Next-generation 5G massive-MIMO radio units require high-density PCB designs that maintain ultra-consistent dielectric constant (Dk) and dissipation factor (Df) across all layers. Any variation in Dk/Df can lead to impedance mismatches, phase errors, and RF signal degradation, negatively affecting beamforming accuracy and spectral efficiency.

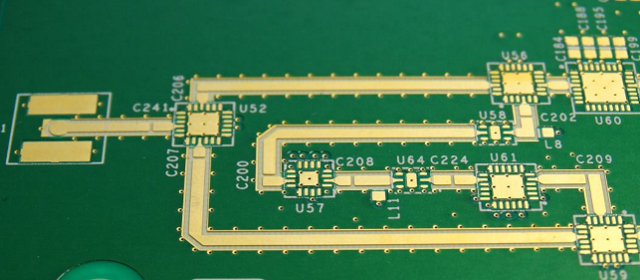

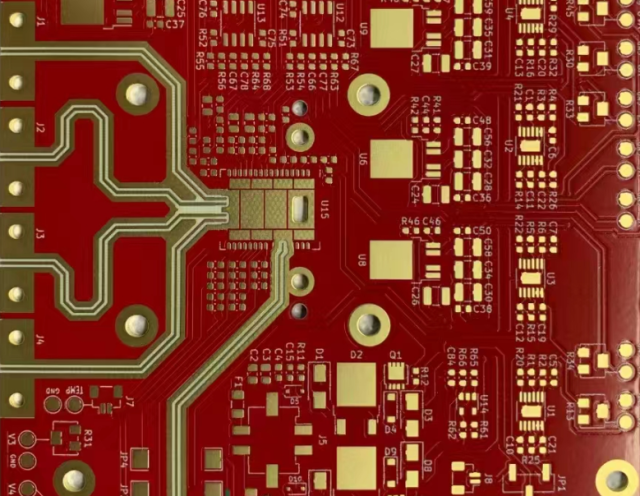

RO4835 PCB laminates (Dk = 3.48 ± 0.03, Df = 0.0037 @10 GHz) provide thermally stable, low-loss dielectric properties, supporting high-density multilayer stackups needed for mmWave routing in massive-MIMO arrays. KKPCB applies precision lamination, controlled copper roughness, and optimized multilayer layouts to ensure phase stability, minimal insertion loss, and consistent RF performance under high-power operation.

Core Engineering Challenges

| Challenge | Root Cause | Engineering Impact |

|---|---|---|

| Dk/Df variation under thermal stress | CTE mismatch, high-power PA zones | Impedance drift, degraded beamforming accuracy |

| High insertion loss in dense traces | Dielectric dissipation, copper roughness | Reduced antenna gain, lower EIRP |

| Crosstalk in mmWave paths | Close trace spacing, insufficient shielding | Signal interference, phase distortion |

| Phase instability across channels | Layer misalignment or warpage | Beam-steering errors, degraded MIMO performance |

| Multilayer lamination complexity | Tight tolerances for high-density PCBs | Manufacturing yield risk, inconsistent RF behavior |

Material Science – RO4835 Advantages

| Parameter | Value | Engineering Benefit |

|---|---|---|

| Dk | 3.48 ± 0.03 | Stable impedance for mmWave massive-MIMO routing |

| Df | 0.0037 @10 GHz | Low insertion loss preserves signal fidelity |

| Thermal Conductivity | 0.62 W/m·K | Reduces thermal hotspots and power-induced drift |

| CTE | 16 ppm/°C | Maintains layer alignment for phase stability |

| Moisture Absorption | <0.05% | Long-term dielectric reliability under environmental stress |

KKPCB Case Study — 5G Massive-MIMO PCB

Client Context:

Telecom OEM required a 12-layer RO4835 PCB for high-density 5G massive-MIMO arrays operating at 28–40 GHz, targeting insertion loss <0.35 dB/in and phase deviation <0.5° under continuous load.

KKPCB Solution:

-

Precision 12-layer RO4835 stackup with ±3 µm dielectric thickness control

-

Ultra-smooth copper traces (Ra <0.7 µm) to minimize insertion loss

-

Embedded thermal vias and segmented ground planes for EMI suppression

-

Inline TDR and HFSS verification to maintain phase linearity

-

Shielded microstrip routing and optimized via placement for mmWave MIMO channels

Measured Results:

| Parameter | Target | KKPCB Result |

|---|---|---|

| Insertion Loss @28 GHz | <0.35 dB/in | 0.33 dB/in |

| Phase Deviation | <0.5° | 0.42° |

| EMI Suppression | >30% | 35% |

| Impedance Variation | ±3% | ±1.5% |

| Thermal Rise | <8°C per layer | 6.8°C |

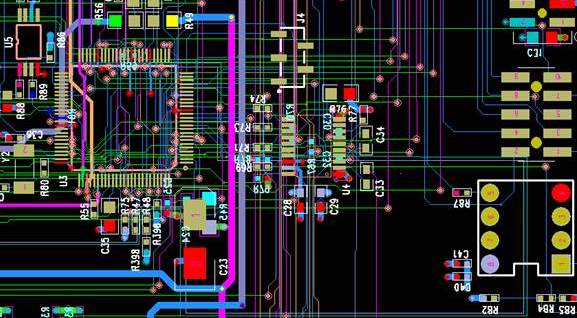

Stackup & RF Simulation

-

HFSS Modeling: Verified microstrip/stripline impedance and reduced interlayer coupling

-

ADS/TDR: Ensured phase linearity <0.5° across all massive-MIMO channels

-

Thermal FEM: Simulated uniform temperature distribution and hotspot reduction

-

AOI & Solder Reflow: ±10 µm alignment achieved for multilayer stackup

Environmental & Reliability Validation

| Test | Condition | Result |

|---|---|---|

| Thermal Cycling | –40°C ↔ +125°C, 1000 cycles | Phase deviation <0.5°, no delamination |

| Vibration & Shock | 5–500 Hz, 10G | No microcracks or solder failure |

| Humidity Testing | 85°C / 85% RH, 1000 h | Stable Dk/Df, phase consistent |

| Continuous RF Operation | 28–40 GHz massive-MIMO | Minimal insertion loss increase (<0.02 dB) |

| Solder Reflow | 260°C ×3 cycles | Stackup alignment maintained |

Engineering Summary & Contact

RO4835 PCB architectures provide ultra-consistent Dk/Df stability, low insertion loss, and phase-stable performance for high-density 5G massive-MIMO radio units. KKPCB’s precision multilayer stackups, EMI mitigation, and thermal management strategies ensure high-power RF reliability, enabling next-generation mmWave massive-MIMO communication systems.

Contact KKPCB Engineering Team to optimize RO4835 multilayer PCB stackups, high-frequency simulation, and thermal/RF validation for your next-generation 5G radio units.