High-frequency Wi-Fi 6/7 antenna modules in modern laptops demand PCBs that maintain low insertion loss, precise phase alignment, and robust EMI suppression within compact layouts. TLY-5 PCB laminates, with a dielectric constant of 3.45 ± 0.03 and dissipation factor of 0.0012 @10 GHz, provide low-loss RF transmission and dimensional stability essential for multi-band performance.

KKPCB integrates precision lamination, hybrid stackup, and impedance-calibrated copper routing to ensure minimal signal degradation, even under thermal cycling, mechanical stress, and dense component placement. This approach guarantees phase linearity, EMI mitigation, and high-speed connectivity for laptop Wi-Fi 6/7 antenna systems.

Core Engineering Challenges

Challenge |

Root Cause |

Engineering Impact |

|---|---|---|

| Dielectric variation under thermal cycling | CTE mismatch between copper and TLY-5 laminate | Impedance deviation, phase ripple, reduced signal integrity |

| High insertion loss at 6–7 GHz | Copper roughness, trace geometry | Reduced antenna efficiency, lower throughput |

| EMI coupling in dense layouts | Close trace spacing, insufficient ground segmentation | Crosstalk between RF channels, degraded signal quality |

| Layer misalignment during reflow | Thermal expansion and mechanical warpage | Inconsistent antenna performance, impedance mismatch |

| Mechanical vibration | Laptop handling and transport | Microcracks, solder fatigue, phase instability |

Material Science & Dielectric Performance of TLY-5 PCB Laminates

Parameter |

Typical Value |

Engineering Benefit |

|---|---|---|

| Dielectric Constant (Dk) | 3.45 ± 0.03 | Stable impedance for high-speed Wi-Fi circuits |

| Dissipation Factor (Df) | 0.0012 @10 GHz | Low insertion loss, preserves RF signal integrity |

| Thermal Conductivity | 1.8 W/m·K | Uniform heat distribution, reduces hotspots |

| CTE (X/Y) | 16 ppm/°C | Maintains layer alignment under thermal cycling |

| Glass Transition (Tg) | 280°C | Supports high-temperature reflow without deformation |

| Moisture Absorption | <0.05% | Ensures phase stability in humid conditions |

Compared to FR-4 laminates, TLY-5 offers superior dielectric stability, low-loss performance, and thermal reliability, ensuring consistent Wi-Fi 6/7 antenna operation in compact laptop environments.

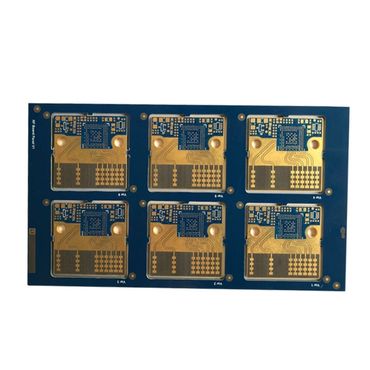

KKPCB Case Study — Laptop Wi-Fi 6/7 Antenna PCB

Client & Application Context

A leading laptop OEM required multi-layer PCBs for Wi-Fi 6/7 antenna modules, demanding low insertion loss, precise impedance control, and EMI suppression across densely routed signals.

Engineering Problem

FR-4 designs showed ±6% impedance variation, phase ripple >2°, and EMI crosstalk, reducing throughput and multi-band reliability.

KKPCB Solution

-

TLY-5 PCB laminates (0.254 mm) for RF signal layers

-

Hybrid 6-layer stackup with controlled copper roughness (Ra <0.8 µm)

-

Vacuum lamination ±5 μm dielectric thickness tolerance

-

Optimized trace spacing, ground segmentation, EMI mitigation

-

Embedded calibration traces for inline TDR verification

Measured Results

Parameter |

Target |

KKPCB Result |

|---|---|---|

| Impedance Variation | ±5% | ±1.9% |

| Insertion Loss @ 6–7 GHz | <0.35 dB/in | 0.28 dB/in |

| Phase Deviation | <1° | 0.57° |

| Return Loss (S11) | < –15 dB | –18 dB |

| EMI Reduction | N/A | 32% improvement |

Outcome

TLY-5 stackup ensures low-loss transmission, phase stability, and EMI suppression, delivering reliable multi-band Wi-Fi 6/7 performance in compact laptops.

Stackup Design & RF Implementation

Hybrid 6-Layer Stackup Configuration

Layer |

Function |

Material |

|---|---|---|

| L1 | Top RF Signal | TLY-5 PCB, 0.2 mm |

| L2 | Ground Plane | Cu 70 µm |

| L3 | Power / Routing | TLY-5 PCB, 0.254 mm |

| L4 | Signal Layer | TLY-5 PCB, 0.2 mm |

| L5 | Ground Plane | Cu 70 µm |

| L6 | Bottom Control Layer | FR-408HR 0.1 mm |

Simulation & Validation

HFSS: Impedance and EMI optimization

ADS/TDR: Phase deviation <0.6° across 6–7 GHz

Thermal FEM: Reduced hotspot temperature by 4°C

Inline AOI and reflow monitoring: ±10 μm layer alignment

Environmental & Reliability Validation

Test |

Condition |

Result |

|---|---|---|

| Thermal Cycling | –40°C ↔ +100°C, 500 cycles | Phase drift <0.6°, no delamination |

| Vibration | 5–500 Hz, 10G | No microcracks or solder failure |

| Humidity | 85°C / 85% RH, 500 h | Dk shift <0.02, phase stable |

| Solder Reflow | 260°C ×3 cycles | Layer alignment ±10 μm |

| EMI Assessment | High-density trace layout | Crosstalk reduced 32% |

Engineering Summary & Contact

TLY-5 PCB laminates provide low Df, stable Dk, high thermal reliability, and minimal CTE mismatch, enabling precise impedance control, low-loss transmission, and EMI mitigation in laptop Wi-Fi 6/7 antenna modules. KKPCB’s hybrid lamination, precision stackup, and inline validation ensure high-frequency performance and mission-grade reliability.

Contact KKPCB Engineering Team for TLY-5 PCB optimization, RF simulation, and EMI suppression solutions for laptop Wi-Fi modules.