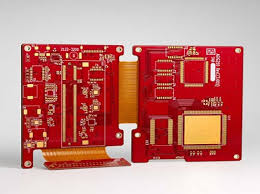

Duroid 6002 PCB: A Technical Deep Dive Into High-Performance Microwave & RF Substrates

1. Introduction: Why Duroid 6002 Matters

As microwave, millimeter-wave, and high-frequency systems increasingly dominate applications such as automotive radar, 5G mmWave systems, satellite communication, phased-array antennas, and aerospace electronics, traditional PCB materials like FR4 fail to meet the stringent electrical and thermal requirements of high-frequency circuits.

Rogers Duroid 6002 is a premium PTFE-based composite engineered specifically for low-loss, high-stability microwave applications.

It bridges the gap between ceramic substrates and conventional PCB laminates, delivering superior RF performance while maintaining manufacturability.

2. Key Material Characteristics of Duroid 6002

Duroid 6002’s performance originates from its highly engineered PTFE-ceramic composite, offering:

-

Low Dk (2.94) with extremely tight tolerance

-

Ultra-low loss tangent (Df ≈ 0.0012)

-

Exceptional dimensional stability

-

Low Z-axis thermal expansion (CTE ≈ 24 ppm/°C)

-

Low moisture absorption (0.03%)

Electrical Properties (25°C)

Property |

Value |

Description |

|---|---|---|

Dielectric Constant (Dk) |

2.94 ± 0.04 | Highly stable across frequency & temperature |

Dissipation Factor (Df) |

0.0012 | Extremely low high-frequency loss |

Z-axis CTE |

24 ppm/°C | Ideal for multilayer & chip-on-board assembly |

Thermal Conductivity |

0.5 W/m·K | Better heat performance than standard PTFE |

Moisture Absorption |

0.03% | Stable in harsh/outdoor environments |

3. Why Duroid 6002 Is Critical for High-Frequency RF Designs

3.1 Industry-Leading Phase Stability

Millimeter-wave systems (24–100 GHz), especially 77 GHz automotive radar or Ka-band satellite links, require extremely stable dielectric properties.

Duroid 6002 features:

-

Low TCDk (~19 ppm/°C)

- Minimal Dk variation across frequency

This results in:

-

More accurate phased-array beam steering

-

Consistent electrical length in transmission lines

-

Better radar resolution & range accuracy

-

Stable system performance over temperature swings

3.2 Lower Loss = Higher Q, Better Efficiency

The low loss tangent of 0.0012 enables:

-

Higher Q resonators

-

Lower insertion loss in microstrip/stripline

-

Improved antenna radiation efficiency

-

Better performance in filters, couplers, and RF feed networks

In the 40–90 GHz band, Duroid 6002 outperforms most PTFE and hydrocarbon laminates.

3.3 Thermal Expansion Matching for RF Chips

Many RF front-end devices (GaAs, GaN, MMICs) require substrates with compatible CTE to avoid mechanical stress.

Duroid 6002’s ceramic-like stability reduces:

-

Solder fatigue

-

Die cracking

-

Delamination during temperature cycling

Thus, it is excellent for:

-

Chip-on-board (COB)

-

Wire bonding

-

High-power PA modules

4. Manufacturing Challenges and KKPCB Solutions

Working with Duroid 6002 requires advanced PCB fabrication techniques. KKPCB provides optimized processes to ensure consistent quality.

4.1 Drilling and Via Metallization

PTFE materials tend to exhibit:

-

Smearing

-

Burrs

-

Poor adhesion in via walls

KKPCB solutions include:

-

Plasma desmear treatment

-

Multi-step controlled-speed drilling

-

Enhanced hole-wall activation

-

Tight copper plating control

Ensures reliable vias and multilayer structures.

4.2 Surface Finishes for RF & Wire Bonding

PTFE surfaces are difficult to plate with standard finishes.

We offer:

-

ENEPIG (wire-bond ready)

-

ENIG for stable RF contact

-

Hard Gold for high-wear connectors

4.3 Multilayer Lamination

Duroid 6002 multilayers require controlled lamination due to PTFE’s thermal behavior.

KKPCB uses:

-

Rogers 3001 / 2929 bondply

-

Precise lamination temperature profiling

-

Vacuum lamination to avoid voids

-

Layer-to-layer dielectric consistency testing

5. Applications of Duroid 6002 PCB

5.1 Automotive 77 GHz Radar Modules

-

Antenna-on-PCB arrays

-

RF feed networks

-

Radar front-end transceiver boards

Low-loss transmission improves radar resolution and detection distance.

5.2 Satellite / Aerospace RF Systems

Ideal for:

-

Ka/Ku band payloads

-

Phased-array satellite antennas

-

High-frequency transceivers

Moisture resistance & thermal stability support long-term reliability in space.

5.3 5G mmWave Modules

Used in:

-

Beamforming antenna modules

-

mmWave PA/LNA matching networks

-

24–40 GHz small-cell units

5.4 Defense & Radar Electronics

Applied in:

-

Missile seeker antennas

-

Active phased-array radars

-

Secure tactical communication systems

Durability, low Dk drift, and thermal stability are mission-critical.

6. Duroid 6002 vs Other High-Frequency Materials

Material |

Dk |

Df |

Strengths |

|---|---|---|---|

| Duroid 6002 | 2.94 | 0.0012 | Best phase stability, excellent CTE |

| Duroid 5880 | 2.20 | 0.0009 | Lowest loss; mechanical weakness |

| RO4350B | 3.48 | 0.0037 | Lower cost, mid-frequency designs |

| Taconic RF-35 | 3.50 | 0.0018 | Good RF cost/performance balance |

→ Duroid 6002 is the preferred choice when phase stability and reliability are top priority.

7. KKPCB Duroid PCB Manufacturing Capabilities

-

2–10 layer Duroid multilayer

-

2.5/2.5 mil line/space

-

±5% impedance control

-

ENEPIG / ENIG / Hard Gold

-

Mixed-material lamination (Duroid + FR4)

-

77 GHz RF testing capability

-

Wire bonding compatibility

KKPCB provides complete engineering support from stack-up design to volume production.

8. Conclusion

Duroid 6002 PCB represents one of the highest-performing microwave substrates available today.

Its exceptional dielectric stability, low loss, and thermal reliability make it a top choice for applications where precision, low attenuation, and long-term dependability are essential.

KKPCB leverages advanced materials expertise and high-end manufacturing to deliver:

Low-loss, high-stability, and mission-grade Duroid 6002 PCB solutions for your RF and microwave designs.