As 5G technology continues to expand across telecommunications, IoT, and industrial applications, the demand for reliable 5G module PCB assembly has grown rapidly. 5G modules integrate high-speed digital circuits, RF front-end components, and antennas into compact form factors, making PCB assembly quality critical to overall system performance.

This article explores the key requirements, challenges, and best practices for successful 5G module PCB assembly.

What Is 5G Module PCB Assembly?

5G module PCB assembly refers to the process of assembling electronic components onto PCBs designed for 5G communication modules. These modules typically include:

-

RF transceivers and power amplifiers

-

Baseband processors

-

High-speed interfaces

-

Antenna connectors and shielding structures

Due to high operating frequencies and dense layouts, 5G module PCB assembly requires advanced PCBA capabilities.

Key Requirements for 5G Module PCB Assembly

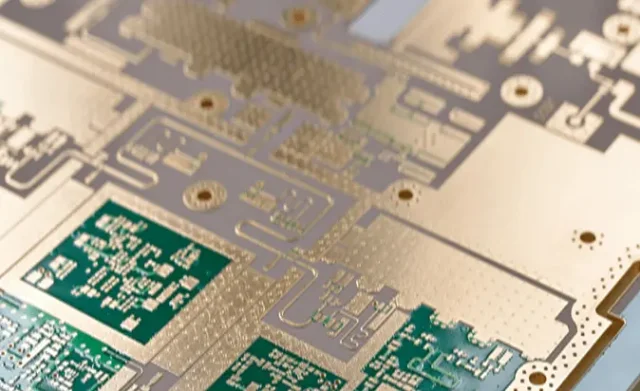

1. High-Frequency PCB Materials

5G modules often use advanced materials such as:

-

Rogers RO4003 / RO4350

-

Taconic RF laminates

-

Hybrid stackups combining RF materials and FR-4

These materials ensure low signal loss, stable impedance, and consistent RF performance.

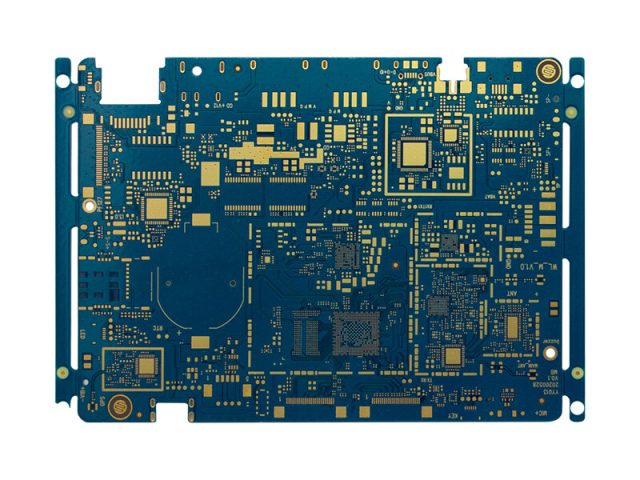

2. Precision SMT Assembly

High-density layouts and fine-pitch components demand:

-

High-accuracy pick-and-place machines

-

Controlled solder paste printing

-

Optimized reflow profiles

Precision SMT assembly ensures proper solder joints and reliable electrical connections.

3. Impedance Control and RF Performance

Accurate impedance control is essential for 5G module PCB assembly:

-

Controlled trace geometry and stack-up

-

RF-sensitive routing and grounding

-

Minimal signal reflection and insertion loss

Maintaining signal integrity directly affects data rate and communication stability.

Quality Control and Testing for 5G Module PCBA

Professional 5G module PCB assembly includes comprehensive testing:

-

AOI (Automated Optical Inspection)

-

X-ray inspection for BGA and QFN packages

-

Functional and RF performance testing

-

Reliability and thermal stress tests

These measures ensure high yield and long-term reliability.

Manufacturing Challenges in 5G Module PCB Assembly

Common challenges include:

-

Dense component placement

-

Mixed RF and digital signal routing

-

Thermal management for high-power RF devices

-

Strict tolerance control

Experienced PCBA manufacturers mitigate these challenges through advanced process control and engineering support.

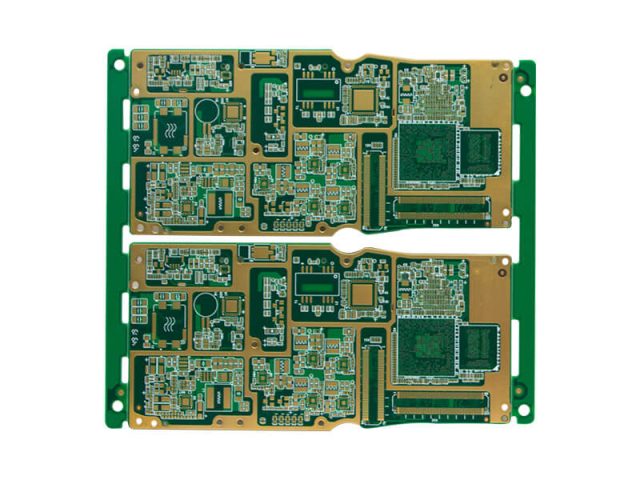

Applications of 5G Module PCB Assembly

5G module PCB assembly is widely used in:

-

5G communication modules

-

IoT and industrial gateways

-

Smart cities and infrastructure

-

Automotive connectivity systems

-

Wireless routers and base stations

Each application requires consistent performance and high reliability.

Conclusion

5G module PCB assembly plays a crucial role in delivering high-performance, reliable 5G communication solutions. From advanced materials and precision SMT to comprehensive testing and quality assurance, every step of the assembly process impacts module performance.

By partnering with an experienced 5G PCBA manufacturer, companies can ensure efficient production, stable RF performance, and scalable manufacturing for next-generation wireless products.