Industrial electronic systems must operate continuously and reliably under extreme environmental and electrical stress.

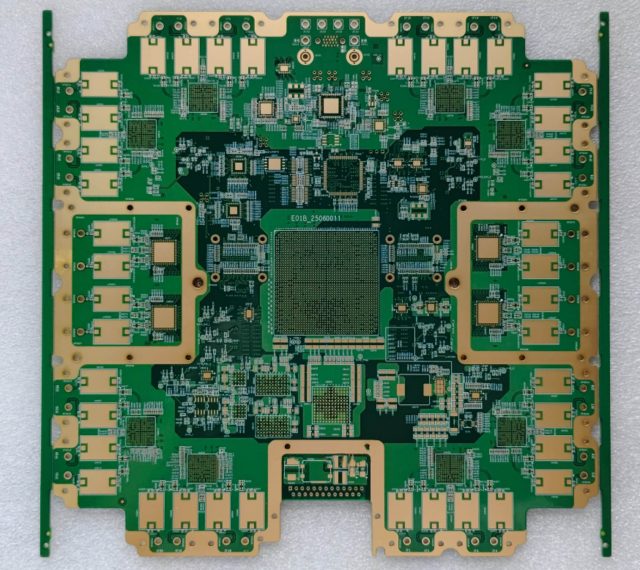

Therefore, an industrial printed circuit board (Industrial PCB) is engineered with rugged materials, reinforced structures, and strict reliability standards to ensure stable long-term performance.

This article explains:

-

What an industrial PCB is

-

How it differs from conventional circuit boards

-

Key materials, design rules, and IPC standards

-

Manufacturing, testing, and quality assurance

-

Real-world industrial applications

What Is an Industrial Printed Circuit Board?

An industrial PCB is a circuit board specifically designed for high-reliability industrial equipment such as:

-

Power supply and energy distribution systems

-

High-voltage motor drives and inverters

-

Building lighting and control systems

-

Industrial automation and manufacturing electronics

These boards support critical electrical functions and must remain operational even when exposed to:

-

Large temperature fluctuations

-

High humidity or corrosive environments

-

Strong vibration and mechanical shock

-

High voltage and high current loads

Because failure may cause safety risks, downtime, or financial loss, industrial PCBs are widely used in:

-

Energy and power industries

-

Industrial automation and robotics

-

Defense and military electronics

-

Aerospace and avionics systems

How Industrial PCBs Differ from Standard PCBs

Industrial circuit boards are designed for greater durability, electrical stability, and service life than commercial or consumer PCBs.

Wide Operating Temperature Range

Industrial-grade PCBs can typically operate from:

−65 °C to +150 °C

This allows reliable performance in outdoor, automotive, and high-heat industrial environments.

Vibration and Shock Resistance

Industrial machinery generates continuous vibration and sudden impact.

To prevent structural failure, industrial PCBs may use:

-

Flexible or rigid-flex substrates to absorb stress

-

Metal-core or reinforced laminates for strength

-

Enhanced solder joint reliability and mechanical fixation

Moisture and Corrosion Protection

Industrial environments often involve humidity, dust, salt spray, oil mist, or chemicals.

Protection methods include:

-

Thick solder mask or conformal coating

-

Corrosion-resistant surface finishes (ENIG, hard gold, etc.)

-

Moisture-resistant laminate materials

High Voltage, High Current, and Thermal Management

Industrial circuits frequently require high power handling, achieved through:

-

Heavy copper traces for large current capacity

-

Thermal vias, heat sinks, or metal-core substrates

-

High-temperature materials such as ceramics or metals

Long Service Life

Compared with consumer electronics, industrial PCBs typically provide:

5 – 15 years of reliable operation, significantly reducing maintenance costs.

Industrial PCB Types and Design Standards

Industrial PCBs are classified by material, structure, and layer configuration.

Types of Industrial Circuit Boards

Rigid PCBs

-

FR-4, high-Tg FR-4, or metal-core substrates

-

High mechanical strength

-

Suitable for fixed industrial installations

Flexible and Rigid-Flex PCBs

-

Polyimide or PTFE materials

-

Withstand bending, vibration, and thermal cycling

-

Ideal for compact or aerospace equipment

Single-Layer and Multilayer PCBs

-

Single-layer: simple applications such as LED lighting

-

Multilayer (4–16+ layers or more): complex routing, impedance control, and EMI shielding

Industrial PCB Reliability Standards

High-reliability industrial PCBs typically comply with IPC Class 3, the strictest quality level.

Important specifications include:

-

IPC-6012E – High-performance rigid PCBs

-

IPC-6012ES – Military and aerospace

-

IPC-6012EM – Medical electronics

-

IPC-6012EA – Automotive electronics

Typical material performance:

-

Tg > 170 °C for thermal stability

-

Thermal conductivity > 0.4 W/m·K

-

Dielectric constant < 4 for signal integrity

-

Thick copper (≥ 2 oz or higher) for power handling

Industrial PCB Manufacturing Process

Industrial PCB production requires special materials, strict design control, and comprehensive testing beyond standard PCB fabrication.

Material Selection for Harsh Conditions

Common materials include:

-

High-Tg FR-4 – cost-effective reliability

-

Polyimide – flexible and heat-resistant

-

Ceramic substrates – RF and high-temperature stability

-

Metal-core PCBs – superior heat dissipation for power and LED systems

Reliability-Focused Design and Layout

Industrial PCB engineering emphasizes:

-

Thick copper for high current

-

Controlled impedance routing

-

Ground planes for EMI suppression

-

Blind/buried vias for multilayer density

-

Redundant traces for fault tolerance

-

Integrated thermal management structures

Prototyping, Production, and Quality Control

Before mass production:

-

Prototypes are fabricated and tested to detect design errors

-

Manufacturing follows strict industry and customer standards

-

Protective coatings and controlled processes enhance durability

Testing and Inspection

Industrial PCBs undergo rigorous reliability validation, including:

-

Automated Optical Inspection (AOI)

-

X-ray inspection

-

In-circuit testing (ICT)

-

Flying-probe testing

-

Burn-in and environmental stress testing

These ensure compliance with UL certification and IPC Class 3 reliability.

Applications of Industrial Printed Circuit Boards

Industrial PCBs are essential in:

-

Motor drives and motion control

-

Power generation and renewable energy

-

Automotive and electric vehicle electronics

-

Industrial automation, robotics, and PLC systems

-

Telecommunications infrastructure

-

Medical and healthcare equipment

-

Aerospace avionics and satellite systems

-

Military and defense electronics

Demand is rapidly increasing in new energy, smart manufacturing, and aerospace, where system reliability is critical.

High-Reliability Industrial PCB Solutions from KKPCB

The aerospace and satellite sectors require extreme precision, tight tolerances, and long-term reliability.

To meet these challenges, KKPCB continuously invests in advanced manufacturing technology, engineering expertise, and quality control systems to deliver:

-

High-performance industrial PCB fabrication

-

Precision multilayer and special-material processing

-

Reliable PCB assembly for mission-critical electronics

Request a Quote for Industrial PCBs

If your project requires:

-

Stable operation in harsh environments

-

High-power or high-temperature capability

-

Certified IPC Class 3 manufacturing quality

Contact KKPCB today for professional engineering support and fast quotation of your industrial PCB solution.