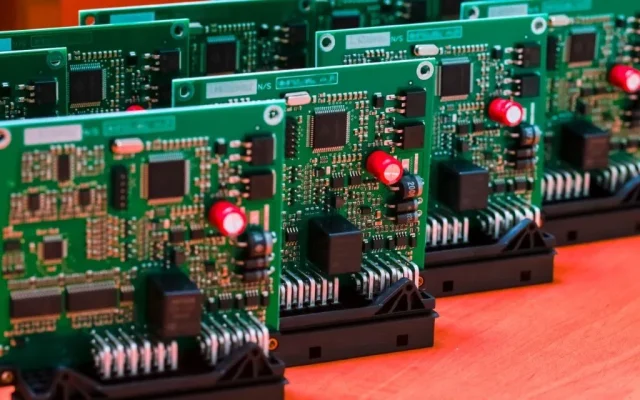

Small Batch PCB manufacturing refers to low-volume PCB production typically ranging from a few pieces to several hundred units, designed to support prototype validation, pilot runs, and early-stage product commercialization. Unlike mass production, Small Batch PCB emphasizes engineering accuracy, process flexibility, and rapid iteration over scale efficiency.

For modern electronics development, Small Batch PCB is a critical bridge between prototype and volume manufacturing.

Why Small Batch PCB Is Essential in Modern Electronics

High-speed signals, RF performance, compact layouts, and advanced packaging have significantly increased PCB design complexity. Small Batch PCB manufacturing enables engineers to validate electrical performance, thermal behavior, and assembly yield before committing to mass production.

Key drivers for Small Batch PCB adoption include:

-

High-mix, low-volume product strategies

-

Rapid design iterations and ECO updates

-

Risk reduction before volume scaling

-

Validation of materials, stackups, and impedance

Small Batch PCB is not simply “low quantity PCB”—it is a controlled engineering process.

Engineering Challenges in Small Batch PCB Production

Producing Small Batch PCB requires tighter process control than mass production because there is less statistical margin for error. Each board must meet design intent precisely.

Common Small Batch PCB challenges include:

-

Controlled impedance consistency at low volumes

-

Material handling for specialty laminates

-

Assembly yield with fine-pitch components

-

Cost control without sacrificing quality

Without strong engineering support, Small Batch PCB projects often suffer from rework, delays, or unreliable test data.

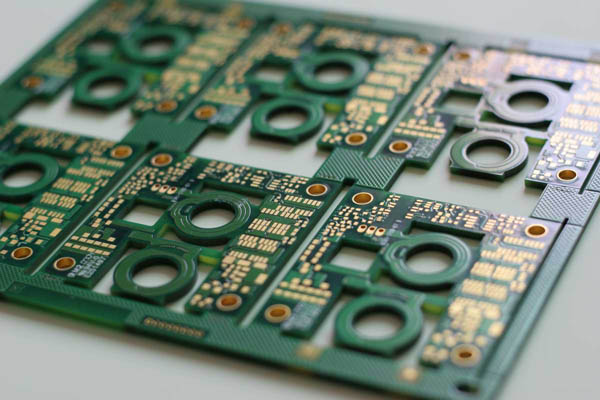

PCB Fabrication Considerations for Small Batch PCB

In Small Batch PCB manufacturing, fabrication parameters are optimized for accuracy rather than throughput. Stackup symmetry, dielectric thickness control, copper balance, and via reliability must be validated carefully.

KKPCB’s Small Batch PCB fabrication focuses on:

-

Tight dielectric thickness tolerance

-

Precise impedance control

-

Advanced via structures (blind, buried, via-in-pad)

-

Compatibility with RF, high-speed, and HDI designs

This ensures that Small Batch PCB results accurately represent future volume production behavior.

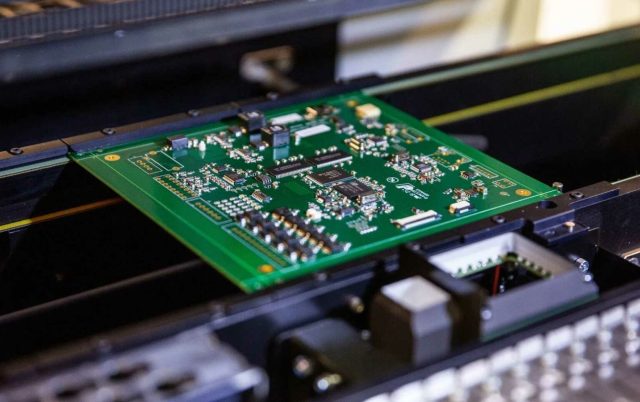

Small Batch PCB Assembly and Process Control

Assembly is often the highest risk stage in Small Batch PCB projects. Fine-pitch BGAs, QFNs, LGA packages, and mixed-technology assemblies demand customized process tuning.

Professional Small Batch PCB assembly integrates:

-

DFM/DFA feedback before production

-

Custom stencil optimization

-

Reflow profile tuning for low-volume runs

-

AOI and X-ray inspection for each lot

This level of control ensures Small Batch PCB assemblies deliver reliable electrical and mechanical performance.

Material and BOM Flexibility in Small Batch PCB

Small Batch PCB projects frequently involve new materials, alternative components, or evolving BOMs. Engineering-led BOM verification is essential to prevent sourcing and assembly conflicts.

Effective Small Batch PCB services support:

-

Prototype-grade material selection

-

Engineering-approved component substitutions

-

Traceable component sourcing

-

Fast response to BOM revisions

This flexibility allows R&D teams to move quickly without compromising quality.

Applications of Small Batch PCB Manufacturing

Small Batch PCB manufacturing is widely used in:

-

New product introduction (NPI)

-

Industrial automation prototypes

-

RF and mmWave module development

-

Medical and instrumentation electronics

-

Aerospace and defense validation builds

In these applications, Small Batch PCB provides confidence before scaling to volume production.

Transition from Small Batch PCB to Mass Production

A key advantage of professional Small Batch PCB manufacturing is smooth scalability. When fabrication parameters, assembly processes, and materials are validated during small batch production, the transition to mass production becomes faster and more predictable.

Engineering-driven Small Batch PCB minimizes design changes and yield loss during scale-up.

KKPCB Small Batch PCB Capabilities

KKPCB specializes in Small Batch PCB fabrication and assembly, supporting high-mix, low-volume projects with strong engineering involvement. From stackup review and impedance modeling to controlled assembly and inspection, KKPCB ensures every Small Batch PCB build meets design intent.

Our Small Batch PCB services are designed to reduce development risk, shorten validation cycles, and accelerate time-to-market.