In the rapidly evolving world of high-frequency electronics, material stability, signal integrity, and cost-effectiveness are key factors in achieving reliable performance. Among the Rogers RO4000® series, Rogers RO4835™ laminate stands out as an advanced high-frequency substrate engineered for superior thermal stability and oxidation resistance — making it ideal for automotive radar, ADAS, and microwave communication systems.

1. Overview of Rogers RO4835™ Laminate

Rogers RO4835™ is a thermoset hydrocarbon laminate reinforced with glass fiber, specifically designed to deliver consistent dielectric properties under extreme operating conditions. It maintains excellent electrical performance even at frequencies beyond 77GHz, enabling designers to achieve stable impedance control and minimal signal loss in high-speed, high-frequency applications.

Unlike conventional PTFE-based materials, RO4835 can be processed using standard FR-4 manufacturing techniques, significantly reducing production costs while maintaining premium performance.

2. Key Features and Advantages

| Feature | Benefit |

|---|---|

| Enhanced Oxidation Resistance | Provides long-term reliability and dielectric stability even at high operating temperatures. |

| Low Dielectric Loss (Df = 0.003) | Ensures minimal signal attenuation in high-frequency radar and RF applications. |

| Stable Dielectric Constant (Dk = 3.48 ± 0.05) | Enables precise impedance control for consistent circuit performance. |

| Lead-Free Compatible | Withstands high-temperature lead-free soldering without blistering or delamination. |

| Low Z-Axis Expansion | Improves plated-through-hole reliability during multiple lamination cycles. |

| Low In-Plane Expansion Coefficient | Enhances dimensional stability throughout PCB fabrication and reflow processes. |

| CAF Resistant | Prevents conductive anodic filamentation, extending long-term PCB reliability. |

These properties make RO4835 an ideal material for multilayer, hybrid, and high-reliability PCB designs, particularly when combined with FR-4 cores for cost optimization.

3. Typical Applications

RO4835™ laminates are engineered for demanding high-frequency and microwave systems where performance, precision, and reliability are critical:

-

77GHz Automotive Radar Systems

Collision avoidance, blind-spot detection, and adaptive cruise control modules. -

Advanced Driver Assistance Systems (ADAS)

High-frequency PCBs for sensor fusion and real-time radar data processing. -

Phased Array and Point-to-Point Microwave Systems

Stable phase response for directional communication antennas. -

Power Amplifiers and RF Components

Low dielectric loss enables efficient power transmission and high gain. -

5G Infrastructure and Wireless Communication

Excellent high-frequency stability and low insertion loss for next-gen RF networks.

4. Processing and Manufacturing Compatibility

One of the main advantages of RO4835™ is its compatibility with standard FR-4 PCB fabrication processes.

It can be drilled, plated, and etched using traditional methods, eliminating the need for special via preparation or PTFE-handling equipment.

With a Tg > 280°C (536°F) and a CTE matched to copper, it maintains dimensional stability and PTH integrity even during multiple lamination cycles or thermal shocks — a major benefit in mixed dielectric multilayer boards (Rogers + FR-4 hybrid stackups).

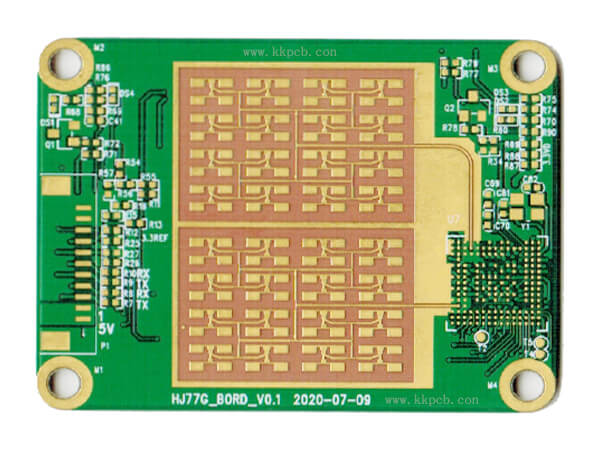

KKPCB leverages these properties to produce hybrid multilayer radar boards combining Rogers RO4835 and IT180 FR-4, delivering both high-frequency performance and cost efficiency for customers worldwide.

5. Technical Summary

| Property | RO4835™ Value |

|---|---|

| Dielectric Constant (Dk) | 3.48 ± 0.05 |

| Dissipation Factor (Df) | 0.0037 @ 10 GHz |

| Thermal Conductivity | 0.69 W/m·K |

| Tg (Glass Transition Temp.) | > 280°C |

| Coefficient of Thermal Expansion (CTE, z-axis) | 32 ppm/°C |

| Lead-Free Compatibility | Yes |

| RoHS Compliance | Yes |

| UL Flammability Rating | UL 94V-0 |

6. Why Choose Rogers RO4835™ for 77GHz Automotive Radar PCBs

Automotive radar systems operating at 77GHz or 79GHz demand extremely low-loss, thermally stable, and oxidation-resistant materials. RO4835 meets these requirements while offering:

✅ High reliability under harsh automotive conditions

✅ Stable performance over wide temperature and frequency ranges

✅ Excellent adhesion and mechanical strength for multilayer designs

✅ Cost-effective processing using conventional FR-4 production lines

These characteristics make Rogers RO4835™ the go-to material for high-performance radar antennas, ADAS systems, and RF front-end modules.

7. Conclusion

The Rogers RO4835™ laminate represents the perfect balance between cost, performance, and processability. With superior dielectric stability, oxidation resistance, and low loss, it enables the next generation of automotive radar, 5G, and microwave systems to operate with higher precision and reliability.

At KKPCB, we integrate RO4835 laminates into advanced hybrid PCB structures (RO4835 + FR-4), providing customers with high-performance, scalable, and cost-optimized PCB solutions for mission-critical applications.