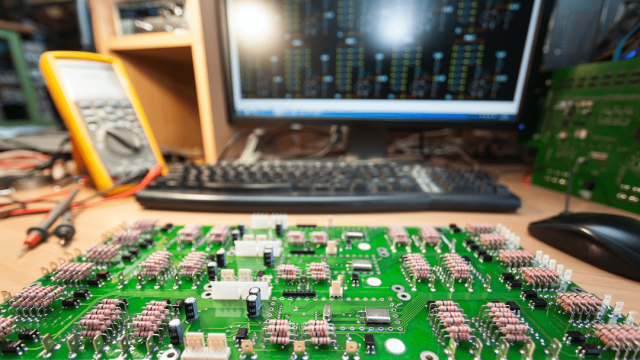

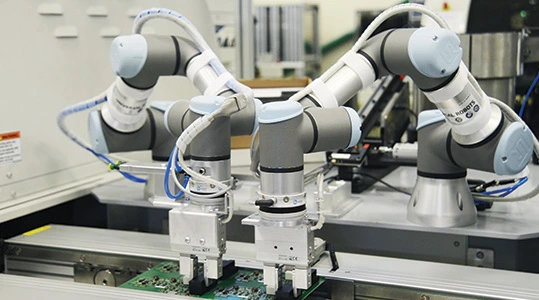

Modern robotics systems—whether industrial robots, autonomous mobile robots (AMRs), AGVs, or collaborative robots—depend on advanced Robotics PCBs as the central platform for sensing, computation, and motion control. As robotic applications expand into high-precision manufacturing, warehouse automation, healthcare, and defense, the engineering requirements for Robotics PCB design continue to escalate.

This article explores the core engineering principles behind high-performance Robotics PCB development and how optimized PCB architecture directly enhances robot intelligence, stability, and safety.

1. High-Speed Signal Architecture for Robotics PCB

A Robotics PCB must support a complex mix of high-speed digital interfaces—CAN, EtherCAT, SPI, MIPI, LVDS, and high-bandwidth camera links. Ensuring signal integrity is critical:

-

Controlled-impedance routing for high-speed buses

-

Matched differential pairs for encoders, vision systems, and LiDAR

-

Strict via-count reduction to minimize reflection and crosstalk

-

Reference-plane continuity to ensure clean return paths

-

Segregation of digital, analog, RF, and motor-driver zones

A well-engineered signal architecture ensures the robot can achieve millisecond-level feedback and real-time control.

2. Power Distribution and High-Current Management in Robotics PCB

Robots combine high-current motors and low-power logic electronics on the same platform. A robust Robotics PCB must maintain stable power distribution under dynamic load:

-

Wide copper pours for motor and servo drivers

-

Low-impedance power planes for logic power rails

-

High-frequency decoupling networks for MCU, DSP, and FPGA

-

Transient suppression for inductive motor back-EMF

-

Thermal relief and copper balancing for high-current regions

Power stability is essential for ensuring robots operate without unexpected shutdowns or controller resets.

3. Multi-Sensor Fusion and Interface Integration

Robotic systems rely on a dense mix of sensors—IMU, LiDAR, ultrasonic, proximity, camera modules, force sensors, and torque encoders. A professional Robotics PCB must integrate these interfaces seamlessly:

-

High-density connectors for sensor modules

-

Ground isolation barriers to reduce sensor noise

-

Differential routing for analog and mixed-signal sensors

-

Shielded traces for noise-sensitive feedback lines

-

On-board edge AI modules for real-time processing

Sensor integration quality determines the robot’s precision, perception accuracy, and motion stability.

4. EMI/EMC Protection for Industrial Robotics PCB

Industrial robots operate in harsh electrical environments surrounded by motors, inverters, welders, and RF equipment. A reliable Robotics PCB must include advanced EMI/EMC engineering:

-

Segmented ground zones and stitching vias

-

Filtering networks on all sensor and communication ports

-

Shielded enclosures for RF-sensitive logic

-

Ferrite beads and LC filters for motor-driver noise

-

Proper PCB stackup to control electromagnetic coupling

Strong EMI/EMC resilience ensures robots maintain stability in electrically noisy factories.

5. Thermal and Mechanical Reliability Engineering

Robotics PCBs frequently experience continuous operation, high ambient temperatures, and mechanical vibration. Engineering considerations include:

-

High-Tg materials for thermal durability

-

Distributed thermal vias under motor drivers, MOSFETs, and FET bridges

-

Mechanical reinforcement around connectors and heavy components

-

Balanced copper distribution to avoid warpage

-

Conformal coating for dust, oil, moisture, and chemical protection

Mechanical and thermal durability directly impacts long-term robotic reliability.

6. Multi-Layer Stackup for High-Density Robotics PCB

Most modern Robotics PCBs operate in the 6-layer to 12-layer range depending on complexity. Ideal stackup principles include:

-

Dedicated power and ground planes for low-impedance performance

-

High-speed layers isolated from noisy power circuits

-

Symmetrical stackup to reduce bending under thermal cycles

-

Hybrid laminates (FR-4 + low-loss materials) for high-speed robotics

A well-engineered stackup enables compact, lightweight, yet robust robotic electronics.

7. Engineering Summary

A high-performance Robotics PCB is the foundation of every advanced robot. By optimizing:

-

High-speed signal routing

-

Power distribution networks

-

Multi-sensor integration

-

EMI/EMC protections

-

Thermal and mechanical reliability

-

Multi-layer stackup

engineers can maximize robotic intelligence, precision, and operational safety.

KKPCB specializes in manufacturing high-density, high-speed, and high-reliability Robotics PCBs, supporting applications from industrial automation to autonomous robotics and collaborative robot systems.