1. Engineering Overview

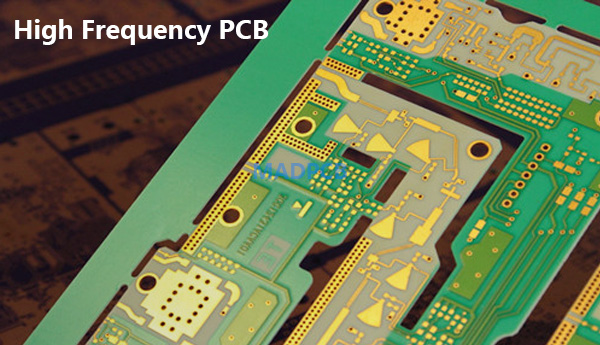

Industrial wireless sensor networks demand high-frequency signal consistency, low insertion loss, and long-term phase stability to maintain accurate sensing and communication. PCBs in these systems must withstand thermal cycling, humidity, and mechanical stress without compromising RF performance. Megtron 7 PCBs, featuring Dk = 3.40 ±0.02 and Df = 0.0018 @ 10 GHz, provide stable dielectric properties and minimal signal attenuation across multilayer sensor boards.

KKPCB applies hybrid lamination, controlled copper surface roughness, and simulation-driven stackup validation to achieve reliable RF transmission and repeatable phase performance in demanding industrial environments.

2. Engineering Context & Technical Challenges

In industrial wireless sensor networks, Megtron 7 PCB substrates face multiple engineering constraints:

| Challenge | Root Cause | Impact on RF/Signal Performance |

|---|---|---|

| Impedance drift | Dielectric fluctuation during lamination | Signal reflection and measurement error |

| Phase instability | CTE mismatch under thermal load | Data synchronization loss |

| Insertion-loss variation | Copper roughness and trace geometry | Reduced RF range and signal clarity |

| Environmental stress | Vibration, humidity, and temperature cycles | Degradation of long-term reliability |

Ensuring phase stability and low-loss performance under these conditions is critical for sensor accuracy and network reliability.

3. Material Science and Performance Characteristics

Megtron 7 PCB laminates provide superior RF performance and environmental stability compared to FR-4 and other conventional materials:

| Property | Megtron 7 | FR-4 | Engineering Impact |

|---|---|---|---|

| Dk @10 GHz | 3.40 ±0.02 | 4.20 ±0.05 | Maintains impedance control |

| Df @10 GHz | 0.0018 | 0.018 | 90% lower signal loss |

| Tg | 210°C | 135°C | High thermal reliability |

| CTE Z-axis | 42 ppm/°C | 70 ppm/°C | Reduced warpage under stress |

| Thermal Conductivity | 0.45 W/m·K | 0.3 W/m·K | Enhanced heat dissipation |

These characteristics enable stable signal propagation and reliable phase behavior across industrial wireless sensor applications.

4. KKPCB Engineering Case Study

Client & Application Context:

A European industrial IoT manufacturer required high-frequency sensor boards for wireless monitoring in harsh factory environments, with stringent phase stability and low insertion loss.

Engineering Problem:

Previous boards using standard laminates exhibited phase deviations up to 1.5° at 28 GHz and insertion-loss variation exceeding 0.3 dB/in under thermal and humidity stress, compromising network accuracy.

KKPCB Solution:

1️⃣ Selected Megtron 7 laminates for stable Dk/Df.

2️⃣ Applied controlled hybrid lamination to minimize dielectric variation.

3️⃣ Optimized differential pair routing, grounding, and via placement.

4️⃣ Performed TDR and HFSS validation for impedance and phase stability across temperature and humidity ranges.

Measured Result:

| Parameter | Design Target | KKPCB Result |

|---|---|---|

| Insertion Loss (28 GHz) | ≤0.30 dB/in | 0.27 dB/in |

| Impedance Tolerance | ±8% | ±3% |

| Phase Deviation | ≤1° | 0.65° |

| Environmental Reliability | Thermal & Humidity cycling | Pass |

Implementation achieved highly repeatable phase behavior and low-loss transmission, ensuring reliable sensor operation in industrial conditions.

5. Stackup Design & RF Implementation

KKPCB utilized a 6-layer hybrid Megtron 7 stackup with low-profile copper (Ra <1 µm), microvia optimization, and controlled ground-plane placement. HFSS and TDR simulations verified impedance uniformity and low crosstalk, supporting long-term sensor network reliability.

6. Reliability & Environmental Validation

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | −40°C to +125°C, 1000 cycles | No delamination, phase deviation <0.7° |

| Humidity Exposure | 85°C / 85% RH, 1000 h | Minimal Df drift, stable impedance |

| Vibration & Shock | Automotive/Industrial standards | Pass, no microvia failure |

| Solder Float | 288°C, 10 sec | Stable adhesion and connectivity |

These results confirm that Megtron 7 PCBs maintain low-loss, phase-stable RF performance under environmental stress.

7. Conclusion — Engineering Reliability Integration

Megtron 7 PCBs enable reliable low-loss transmission and phase stability in industrial wireless sensor networks. Through KKPCB’s hybrid lamination, stackup optimization, and RF validation, these boards deliver predictable high-frequency performance, robust environmental reliability, and long-term operational consistency.

Material uniformity combined with precision fabrication ensures accurate sensing, stable communication, and dependable IoT network performance.

8. Contact / CTA

Contact KKPCB Engineering Team for stackup design, impedance verification, and environmental reliability validation using Megtron 7 PCBs for industrial IoT, automotive radar, 5G, and aerospace RF modules.