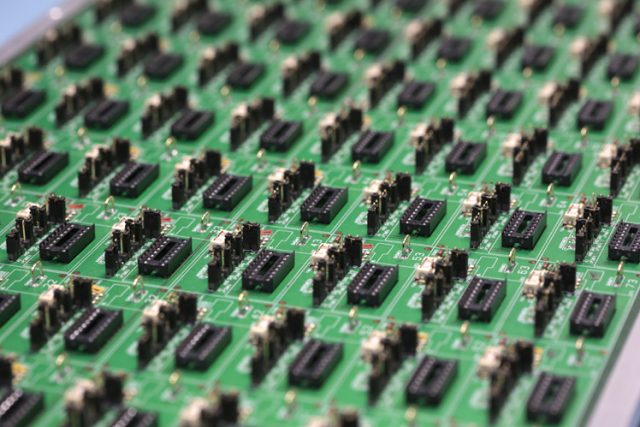

In semiconductor manufacturing, probe cards play a critical role in wafer testing before packaging. The Probe Card Assembly PCB is the core structural and electrical platform that integrates probes, connectors, and signal routing. Its quality directly impacts test accuracy, yield rate, and overall production efficiency. Due to extremely fine pitches, high-frequency signals, and strict impedance requirements, probe card PCBs demand advanced fabrication and assembly technologies.

Key Functions of Probe Card Assembly PCB

- Signal Transmission: Ensures stable and low-loss signal paths between ATE and wafer pads.

- Mechanical Support: Provides structural stability for probe needles or MEMS probes.

- High-Density Interconnection: Supports ultra-fine traces, microvias, and multilayer stack-ups.

- Thermal Management: Maintains electrical performance under repeated test cycles.

Technical Requirements

Probe Card Assembly PCBs are among the most demanding PCB products in the industry:

- Ultra-fine line/space (down to 30/30 μm or below)

- Multilayer structures (often 10–40 layers)

- Controlled impedance for high-speed signals

- Low-Dk and low-Df materials for signal integrity

- High planarity and tight dimensional tolerances

- Reliable via-in-pad and microvia structures

Materials Commonly Used

- High-performance FR-4

- Polyimide (PI)

- BT resin

- Low-loss laminates for high-frequency testing

Assembly Challenges

- Precise alignment of probes and connectors

- Strict cleanliness control to avoid contamination

- High-reliability soldering and bonding processes

- Electrical testing to ensure signal integrity and continuity

Applications

Probe Card Assembly PCBs are widely used in:

- Wafer test and die sort processes

- Logic IC testing

- Memory chip testing (DRAM, NAND)

- RF and mixed-signal IC testing

- Advanced semiconductor R&D and validation

Importance of a Reliable PCB Manufacturer

Choosing an experienced PCB manufacturer for probe card assembly is essential. Advanced equipment, strict process control, and in-depth understanding of semiconductor test requirements ensure consistent performance and long service life of probe cards.

Conclusion

Probe Card Assembly PCB is a critical enabler in semiconductor wafer testing. With the continuous advancement of IC technology and shrinking node sizes, the demand for higher precision, higher density, and higher reliability probe card PCBs will continue to grow. Partnering with a professional PCB and PCBA supplier ensures optimal test performance and long-term cost efficiency.