Why PCB Turnkey Matters in Modern Electronics Manufacturing

As electronic systems become more complex, managing separate suppliers for PCB fabrication, component sourcing, assembly, and testing introduces cost risk, schedule delays, and quality uncertainty. This is especially true for products involving high-speed digital signals, RF circuits, power electronics, or mixed-technology assemblies.

PCB turnkey solutions address this challenge by providing a single, integrated manufacturing workflow. From bare PCB fabrication to finished PCBA delivery, PCB turnkey services reduce coordination complexity and allow engineering teams to focus on product performance rather than supplier management.

What Is PCB Turnkey Service?

PCB turnkey refers to a one-stop manufacturing model that covers the complete lifecycle of a PCB-based product, typically including:

-

PCB fabrication based on Gerber and stackup requirements

-

Electronic component sourcing and BOM management

-

SMT and THT assembly

-

Functional testing and quality inspection

-

Packaging and global logistics

In a turnkey PCB model, the manufacturer takes responsibility for material compatibility, process integration, and delivery consistency, ensuring that design intent is preserved throughout production.

Engineering Value of PCB Turnkey Manufacturing

Design-to-Manufacturing Consistency

One of the biggest advantages of PCB turnkey service is the elimination of disconnects between fabrication and assembly. At KKPCB, PCB layout, stackup design, and assembly processes are evaluated as a unified system. This ensures:

-

Stackups optimized for both signal integrity and assembly yield

-

Pad geometries aligned with real soldering behavior

-

Via structures compatible with SMT and reflow processes

This integration significantly improves first-pass yield, especially for HDI PCB, controlled impedance PCB, and RF PCB assemblies.

BOM Control and Component Risk Management

Component availability and substitution risk are critical issues in today’s supply chain. KKPCB’s PCB turnkey service includes:

-

BOM verification and part number validation

-

Alternative component recommendations when shortages occur

-

Traceability control for critical and high-reliability components

By managing sourcing internally, PCB turnkey services reduce unexpected redesigns and ensure electrical compatibility across production runs.

PCB Turnkey Process at KKPCB

PCB Fabrication Engineering

KKPCB manufactures PCBs covering:

-

Heavy copper and power PCBs

Each PCB turnkey project starts with stackup engineering and DFM review to ensure manufacturability before fabrication begins.

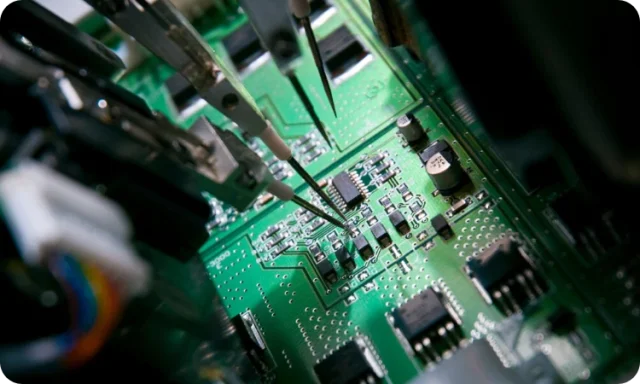

Assembly and Process Control

PCB turnkey assembly at KKPCB supports:

-

High-density SMT with fine-pitch components

-

Mixed SMT + THT assemblies

-

BGA, QFN, LGA, and RF module packaging

-

Selective soldering and wave soldering

Process controls include AOI, X-ray inspection, and reflow profile optimization to ensure assembly reliability.

Testing and Quality Assurance

To ensure functional reliability, KKPCB integrates multiple testing stages into its turnkey PCB workflow:

-

Electrical continuity and insulation testing

-

Functional testing based on customer requirements

-

Visual and automated inspection

-

Reliability screening for industrial and mission-critical applications

This testing-centric approach ensures that turnkey PCB assemblies meet real-world operating conditions, not just visual standards.

Applications Best Suited for PCB Turnkey Services

PCB turnkey solutions are particularly effective for:

-

New product introduction (NPI) and rapid prototyping

-

High-speed computing and communication systems

-

RF transceivers and wireless modules

-

Industrial automation and control electronics

-

Medical, automotive, and aerospace electronics

In these applications, the cost of misalignment between PCB design and assembly far outweighs the cost of an integrated turnkey approach.

PCB Turnkey vs. Consignment Model

Unlike consignment assembly—where customers supply components—PCB turnkey services place responsibility for procurement, compatibility, and delivery on the manufacturer. This reduces management overhead and provides clearer accountability for quality and timelines.

For engineering teams seeking predictable outcomes and scalable production, PCB turnkey manufacturing offers a more robust and efficient solution.

Conclusion

PCB turnkey services are no longer just a convenience—they are a strategic manufacturing model for modern electronics development. By integrating PCB fabrication, component sourcing, assembly, and testing, KKPCB’s turnkey PCB solutions reduce risk, shorten development cycles, and improve product reliability.

From prototype to mass production, KKPCB delivers PCB turnkey services designed to support complex designs, demanding performance requirements, and global delivery needs.