What Is PCB Turnkey Service?

PCB Turnkey refers to a complete solution where a single supplier manages the entire process from PCB fabrication, component procurement, PCB assembly, testing, and final product delivery. Turnkey PCB services allow customers to outsource complex supply chain management and focus on product development.

Turnkey PCB assembly is widely used in industries requiring fast production, high reliability, and simplified procurement processes.

Types of PCB Turnkey Services

PCB Turnkey services are generally divided into several service models:

Full Turnkey PCB

The manufacturer handles PCB fabrication, component sourcing, assembly, testing, and final delivery. Customers only need to provide design files and BOM.

Partial Turnkey PCB

Customers supply some components while the supplier manages PCB manufacturing and assembly.

Consigned PCB Assembly

Customers provide all components and the manufacturer performs PCB assembly and testing only.

Each PCB turnkey model provides flexibility based on customer supply chain preferences.

PCB Turnkey Service Process

A professional PCB Turnkey process typically includes:

Design File Review

Engineering teams perform DFM and DFA analysis to ensure manufacturability and assembly reliability.

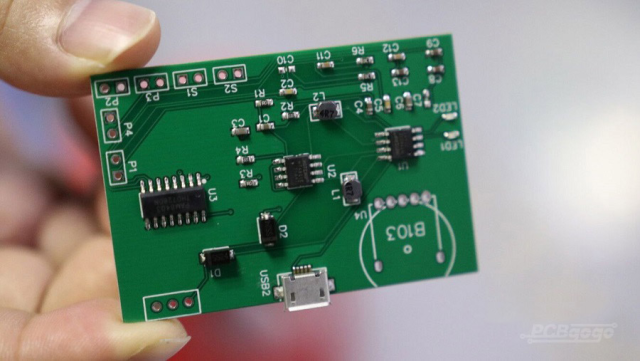

PCB Fabrication

Printed circuit boards are produced according to customer specifications and stack-up requirements.

Component Sourcing

Turnkey PCB suppliers procure components through reliable global supply channels to ensure authenticity and availability.

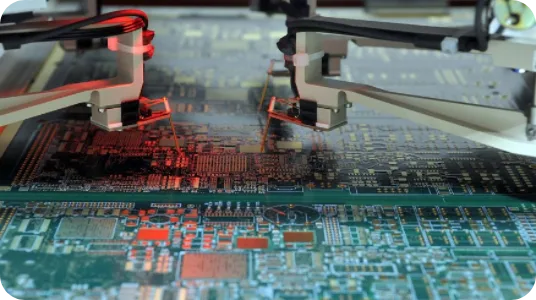

PCB Assembly

Automated SMT assembly and through-hole soldering ensure accurate and consistent component placement.

Testing and Quality Control

Turnkey PCB services include multiple testing methods such as AOI, X-ray inspection, functional testing, and burn-in testing.

Packaging and Delivery

Finished PCB assemblies are packaged and shipped according to customer requirements.

Advantages of PCB Turnkey Services

Choosing PCB Turnkey solutions offers several key benefits:

Simplified Supply Chain Management

Customers work with a single supplier instead of managing multiple vendors.

Reduced Production Time

Integrated PCB fabrication and assembly shorten overall lead time.

Lower Procurement Risk

Experienced suppliers manage component sourcing and supply chain challenges.

Improved Quality Control

Unified production and assembly processes reduce compatibility issues.

Cost Efficiency

Turnkey PCB services help optimize material procurement and manufacturing cost.

Quality Assurance in PCB Turnkey Manufacturing

Reliable PCB Turnkey suppliers implement strict quality control procedures, including:

-

Incoming material inspection

-

Automated optical inspection (AOI)

-

X-ray solder joint inspection

-

Functional testing and reliability verification

-

Traceability and quality documentation

These quality assurance measures ensure high reliability and consistent performance.

Applications of PCB Turnkey Services

PCB Turnkey solutions are widely used across multiple industries, including:

-

Consumer electronics manufacturing

-

Industrial automation systems

-

Automotive electronics and ADAS modules

-

Medical device electronics

-

Communication and networking equipment

-

Aerospace and defense electronics

-

IoT devices and smart technology products

-

Semiconductor test and evaluation systems

Turnkey PCB services help accelerate product development and mass production across these sectors.

How to Choose a PCB Turnkey Supplier

Selecting the right PCB Turnkey partner is critical for project success. Important factors include:

-

Engineering support capability

-

Component sourcing reliability

-

Manufacturing and assembly capacity

-

Quality certification and inspection standards

-

Supply chain stability

-

Experience with complex PCB technologies

Working with an experienced PCB Turnkey manufacturer ensures efficient production and reliable delivery.

Conclusion

PCB Turnkey services provide a comprehensive manufacturing solution that integrates PCB fabrication, component procurement, assembly, and testing into a streamlined production process. By simplifying supply chain management and improving production efficiency, PCB turnkey services help companies accelerate product development and reduce operational risks.

Partnering with a professional PCB Turnkey supplier ensures consistent quality, reliable sourcing, and efficient production from prototype to mass manufacturing.