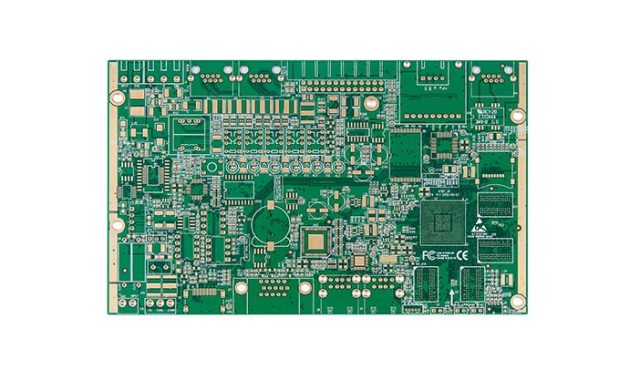

Choosing a PCB supplier direct model allows electronics companies to work directly with a PCB manufacturing factory, eliminating intermediaries and improving cost efficiency, communication speed, and quality control. In today’s fast-paced electronics market, direct collaboration with a PCB supplier has become a preferred choice for engineers, purchasing teams, and OEMs.

A reliable PCB supplier direct partner supports projects from PCB prototyping through volume production, ensuring consistent quality and shorter lead times.

What Does PCB Supplier Direct Mean?

A PCB supplier direct refers to purchasing printed circuit boards directly from the manufacturer rather than through trading companies or distributors. This direct factory model provides customers with better pricing, clearer technical communication, and greater control over manufacturing processes.

Working with a direct PCB supplier enables faster engineering feedback and reduces the risk of miscommunication during design and production.

Advantages of Working with a PCB Supplier Direct

Cost Efficiency

A PCB supplier direct eliminates extra margins charged by middlemen, resulting in more competitive pricing for both prototype and mass production orders.

Direct Engineering Communication

Direct access to PCB engineers allows faster DFM feedback, material selection support, and problem-solving during fabrication.

Better Quality Control

A direct PCB manufacturer manages all production processes in-house, ensuring stable quality standards and consistent process control.

Shorter Lead Time

PCB supplier direct services reduce communication layers, enabling faster response times and shorter production cycles.

Flexible Customization

Direct PCB suppliers can better support customized stack-ups, special materials, controlled impedance, and complex PCB structures.

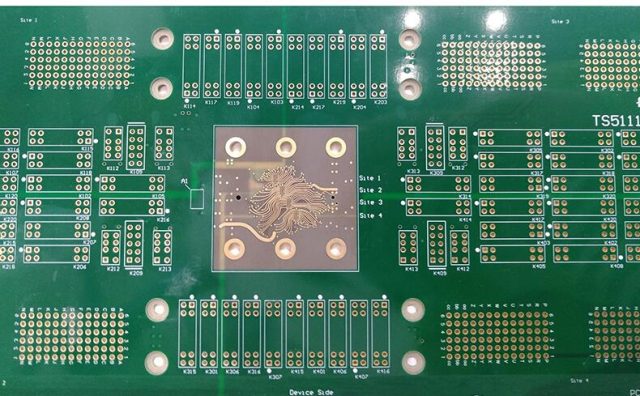

Capabilities Offered by a PCB Supplier Direct

A professional PCB supplier direct typically provides comprehensive manufacturing capabilities, including:

-

PCB prototype and quick-turn services

-

Multilayer and HDI PCB manufacturing

-

Controlled impedance PCB production

-

High frequency and RF PCB fabrication

-

Rigid-flex and flex PCB manufacturing

-

Small batch and mass production support

-

OEM and EMS PCB solutions

These capabilities allow customers to scale smoothly from development to production.

PCB Supplier Direct for Prototype to Mass Production

One major advantage of choosing a PCB supplier direct is lifecycle support. Prototype validation helps confirm electrical performance and manufacturability, while consistent materials and processes ensure stable performance during volume production.

This continuity significantly reduces redesign risk and production delays.

Industries Served by PCB Supplier Direct

PCB supplier direct services are widely used in:

-

Telecommunications and 5G equipment

-

Automotive electronics and ADAS systems

-

Industrial automation and robotics

-

Consumer electronics and IoT devices

-

Medical electronics

-

Aerospace and defense applications

In all these industries, direct PCB manufacturing ensures higher reliability and faster time-to-market.

PCB Supplier Direct vs Trading Company

| Aspect | PCB Supplier Direct | Trading Company |

|---|---|---|

| Price | More competitive | Higher cost |

| Communication | Direct with engineers | Indirect |

| Lead Time | Shorter | Longer |

| Quality Control | Factory-managed | Limited |

| Custom Support | Strong | Restricted |

Choosing a PCB supplier direct model provides clear advantages for complex and high-reliability PCB projects.

Conclusion

Working with a PCB supplier direct offers clear benefits in cost, quality, communication, and delivery speed. By partnering directly with a PCB manufacturer, customers gain better control over design validation, manufacturing consistency, and long-term supply stability.

As electronic products become more complex and time-to-market pressures increase, choosing a reliable PCB supplier direct is a strategic decision that supports successful product development and scalable production.