In today’s electronics supply chain, uncertainty in cost, quality, and delivery can delay product launches and increase risk. Choosing a PCB supplier direct—working directly with the PCB factory rather than intermediaries—gives customers greater control over every critical manufacturing variable.

A direct PCB supplier relationship transforms procurement from a transactional process into a strategic manufacturing partnership.

What Makes PCB Supplier Direct Different?

A PCB supplier direct model means the customer communicates and places orders directly with the PCB manufacturer. This direct connection eliminates layers between engineering intent and actual production execution.

With a PCB supplier direct, you gain:

-

Direct access to manufacturing engineers

-

Clear visibility into materials and processes

-

Faster feedback on design and DFM questions

-

Factory-level accountability

This transparency is essential for complex or performance-critical PCBs.

Cost Transparency and Pricing Control

One of the biggest advantages of a PCB supplier direct is pricing clarity. Factory-direct sourcing avoids:

-

Distributor markups

-

Broker handling fees

-

Hidden cost buffers

Instead, customers receive:

-

True manufacturing cost breakdowns

-

Clear impact of materials, layer count, and tolerances

-

Predictable pricing for repeat and volume orders

This is especially valuable for high-frequency, multilayer, and controlled impedance PCBs where cost drivers are highly technical.

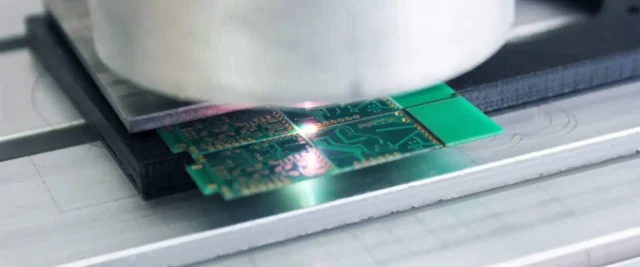

Faster Engineering Communication and DFM Optimization

Working with a PCB supplier direct shortens the feedback loop between design and production. Engineers can:

-

Review stackups and impedance requirements early

-

Suggest manufacturable alternatives

-

Identify risk areas before fabrication

This reduces redesign cycles, prevents delays, and improves first-pass yield—critical for tight development schedules.

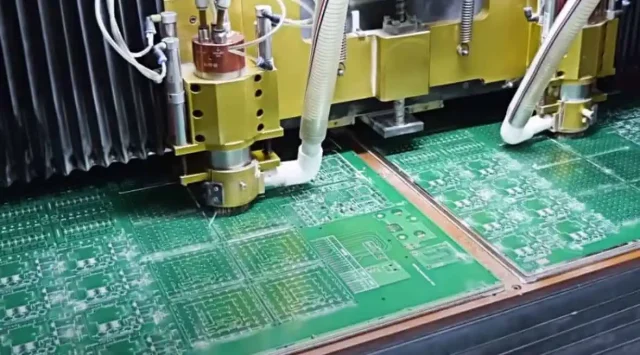

Quality Ownership and Manufacturing Accountability

When sourcing through multiple intermediaries, responsibility can become fragmented. With a PCB supplier direct, quality ownership remains with the factory.

Direct suppliers provide:

-

In-house quality control and inspection

-

Electrical testing and impedance verification

-

Full production traceability

-

Immediate root-cause analysis if issues arise

This level of accountability is vital for automotive, RF, industrial, and aerospace applications.

Lead Time Reliability and Supply Stability

A PCB supplier direct manages production schedules internally, allowing:

-

More accurate lead time commitments

-

Priority handling for urgent builds

-

Better coordination during material shortages

Direct communication helps align production planning with customer demand, reducing uncertainty and delivery risk.

Ideal Applications for PCB Supplier Direct Sourcing

Factory-direct PCB sourcing is especially beneficial for:

-

High frequency and RF PCBs

-

Controlled impedance and high-speed designs

-

Multilayer and HDI boards

-

Automotive and industrial electronics

-

Prototype-to-mass-production programs

These applications require tight control over performance and consistency.

How to Evaluate a PCB Supplier Direct Partner

When choosing a PCB supplier direct, consider:

-

Engineering support capability

-

Material and process expertise

-

Quality systems and inspection methods

-

Scalability from prototype to volume

-

Communication speed and clarity

A strong direct supplier acts as an extension of your engineering and procurement teams.

Conclusion

Choosing a PCB supplier direct provides more than cost savings—it delivers control, transparency, and reliability across the entire PCB manufacturing process. By working directly with the factory, customers gain faster engineering support, consistent quality, predictable lead times, and reduced supply chain risk.

For companies building performance-critical or high-volume electronics, a PCB supplier direct relationship is a strategic advantage.