What Is a PCB Prototype Order?

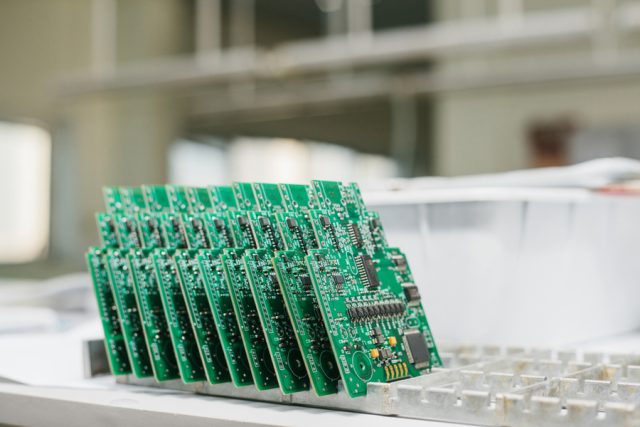

A PCB prototype order refers to the fabrication of a small batch of printed circuit boards used for design verification, functional testing, and performance validation before moving to mass production. PCB prototype orders are a critical step in the electronics development cycle, helping engineers identify design issues early and reduce overall project risk.

Unlike volume production, a PCB prototype order focuses on speed, flexibility, and accuracy, ensuring the prototype closely matches the final production board.

Why PCB Prototype Order Is Important

Placing a PCB prototype order provides several key benefits:

-

Early detection of design and layout issues

-

Verification of electrical performance and signal integrity

-

Mechanical fit and assembly validation

-

Reduced risk before mass production

-

Shorter development and iteration cycles

A well-managed PCB prototype order saves both time and cost in later production stages.

Key Requirements for PCB Prototype Order

To ensure a successful PCB prototype order, several technical and logistical factors must be considered:

-

Complete design files

Gerber, drill files, stack-up details, and impedance requirements. -

Material selection

FR-4, high-frequency, HDI, or specialty materials depending on application. -

Layer count and board complexity

-

Controlled impedance and tolerance requirements

-

Surface finish options

ENIG, HASL, OSP, or immersion silver.

Clear specifications help PCB manufacturers deliver accurate prototype boards.

PCB Prototype Order Manufacturing Process

A standard PCB prototype order process typically includes:

-

Design file review (DFM/DFA)

Identifies potential manufacturing or assembly risks. -

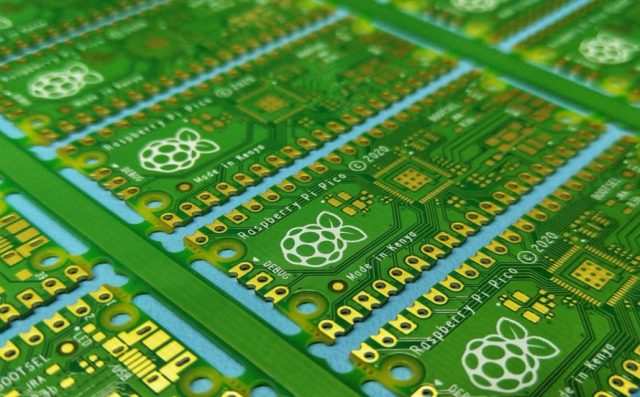

Prototype PCB fabrication

Imaging, etching, drilling, lamination, and finishing. -

Inspection and electrical testing

AOI and 100% electrical testing ensure basic functionality. -

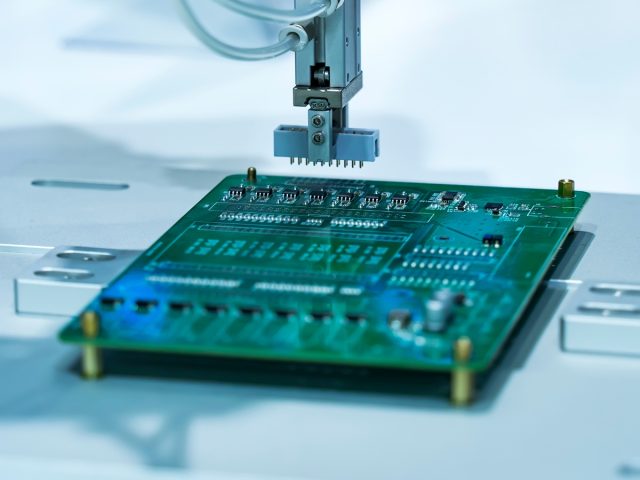

Optional prototype PCB assembly (PCBA)

SMT, THT, or mixed assembly for functional testing. -

Packaging and shipment

Fast and secure delivery to support rapid iteration.

Efficient workflow is key to fast-turn PCB prototype orders.

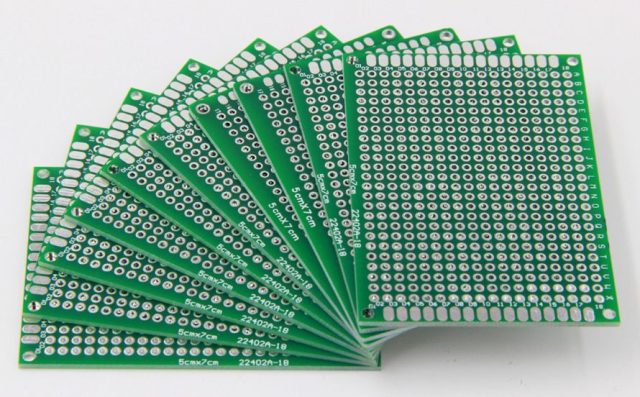

Fast Turn PCB Prototype Order Options

Many PCB suppliers offer quick-turn PCB prototype order services, including:

-

24-hour / 48-hour PCB prototypes

-

Small quantity prototype runs

-

Engineering support during prototyping

-

Rapid revisions for design iterations

Fast prototype PCB orders are especially valuable for startups, R&D teams, and time-sensitive projects.

Applications of PCB Prototype Order

PCB prototype orders are widely used in:

-

New product development (NPD)

-

R&D and engineering validation

-

Automotive and industrial electronics

-

Medical device development

-

Telecommunications and IoT projects

Almost every electronic product begins with a PCB prototype order.

How to Choose a PCB Prototype Order Supplier

When selecting a supplier for PCB prototype orders, consider:

-

Turnaround time and delivery reliability

-

Manufacturing capability and process control

-

Engineering and DFM support

-

Quality inspection standards

-

Ability to scale from prototype to mass production

A supplier that supports both prototype and volume production ensures smoother project transition.

Conclusion

A PCB prototype order is a vital step in turning electronic designs into reliable products. By choosing a capable PCB manufacturer offering fast turnaround, engineering support, and consistent quality, engineers can accelerate development and reduce time-to-market.

Reliable PCB prototype order services help bridge the gap between design and mass production with confidence.