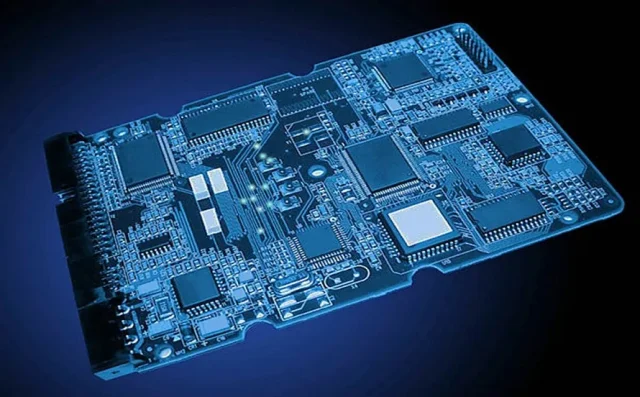

What Is a PCB Prototype?

A PCB prototype is a small-quantity printed circuit board produced to verify circuit design, layout, and functionality before full-scale manufacturing. PCB prototypes are essential during the early stages of product development to reduce design risk and shorten time to market.

Engineers rely on PCB prototyping to test electrical performance, mechanical fit, and assembly compatibility.

Why PCB Prototype Is Important

Using a PCB prototype provides several key benefits:

-

Early detection of design errors

-

Verification of electrical and signal integrity

-

Evaluation of materials and stack-up

-

Functional testing before mass production

-

Reduced development cost and risk

A reliable PCB prototype helps ensure a smooth transition to production.

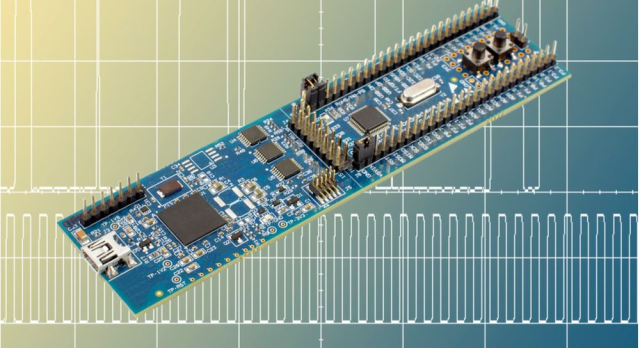

PCB Prototype Manufacturing Capabilities

Professional PCB prototype services typically support:

-

Single-layer to multilayer PCB prototypes

-

HDI PCB prototypes

-

Impedance controlled PCB prototypes

-

RF and high-frequency PCB prototypes

-

Rigid, flex, and rigid-flex PCB prototypes

-

Special materials and hybrid stack-ups

These capabilities support a wide range of engineering requirements.

PCB Prototype Lead Time Options

Fast turnaround is a key advantage of PCB prototyping:

-

Standard prototype lead time: 5–7 working days

-

Quick-turn PCB prototype: 24–72 hours

-

Engineering review and DFM support before fabrication

Flexible lead time options allow engineers to meet tight development schedules.

Applications of PCB Prototype

PCB prototypes are widely used in:

-

Product development and R&D

-

Electronics design verification

-

RF and communication systems

-

Automotive and industrial electronics

-

Medical and aerospace electronics

-

Semiconductor test and evaluation

Every successful product starts with a reliable PCB prototype.

From PCB Prototype to Mass Production

After prototype validation, designs can be smoothly transferred to:

-

Pilot production

-

Small-batch manufacturing

-

Full-scale mass production

Working with the same PCB supplier ensures process consistency, quality stability, and faster scale-up.

Conclusion

A PCB prototype is a critical step in electronic product development, enabling fast design validation and risk reduction. With advanced manufacturing capabilities and fast turnaround, PCB prototyping accelerates innovation and improves product reliability.

Choosing an experienced PCB prototype manufacturer ensures accurate fabrication, professional engineering support, and on-time delivery from prototype to production.