In today’s competitive electronics market, cost control, delivery speed, and manufacturing reliability are critical. Choosing PCB factory direct manufacturing allows companies to source printed circuit boards directly from the production facility, eliminating intermediaries and gaining full transparency over pricing, lead time, and quality control.

For prototype development, engineering validation, and mass production, PCB factory direct sourcing has become the preferred solution for global electronics manufacturers.

What Is PCB Factory Direct Manufacturing?

PCB factory direct manufacturing means purchasing PCBs directly from the PCB fabrication factory rather than through agents or trading companies. In this model, customers work directly with:

-

PCB process engineers

-

Production management teams

-

Quality assurance departments

Direct communication ensures technical accuracy and faster response throughout the manufacturing process.

Why Choose PCB Factory Direct?

Direct Factory Pricing and Cost Control

One of the strongest advantages of PCB factory direct sourcing is transparent pricing:

-

No distributor or trader markup

-

Direct factory cost structure

-

Engineering-driven cost optimization

This makes PCB factory direct manufacturing ideal for both short-term projects and long-term supply agreements.

Shorter Lead Time and Faster Turnaround

With PCB factory direct, communication delays are reduced:

-

Faster DFM feedback

-

Immediate engineering clarification

-

Quicker production scheduling

This significantly shortens prototype and production lead times.

In-House Quality Control

PCB factory direct manufacturing provides:

-

Full in-house process monitoring

-

On-site quality inspection at every step

-

Immediate corrective action when deviations occur

Direct quality control improves yield and long-term reliability.

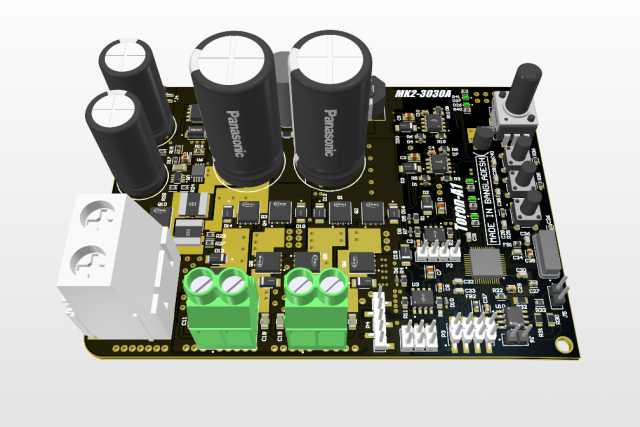

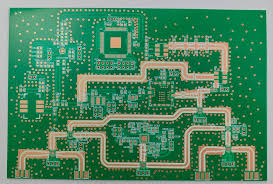

PCB Factory Direct Capabilities

A professional PCB factory direct manufacturer typically offers:

-

Single-layer to multilayer PCB fabrication

-

High-frequency and high-speed PCB manufacturing

-

Controlled impedance PCB production

-

Advanced surface finishes (ENIG, OSP, Immersion Silver, Immersion Tin)

-

Electrical testing and reliability inspection

These capabilities ensure stable performance from prototype to mass production.

PCB Factory Direct for Prototype and Mass Production

PCB factory direct manufacturing supports:

-

Quick-turn PCB prototypes

-

Small batch and pilot production

-

Medium and high-volume mass production

This scalability allows customers to move smoothly from R&D to commercial production.

Industries That Benefit from PCB Factory Direct Sourcing

PCB factory direct manufacturing is widely used in:

-

Consumer electronics

-

Industrial automation

-

RF and high-frequency systems

-

Communication and networking equipment

-

Automotive and advanced electronics

These industries benefit from cost efficiency, stable supply, and technical support.

How to Select a Reliable PCB Factory Direct Partner

When choosing a PCB factory direct manufacturer, evaluate:

-

Manufacturing capacity and equipment

-

Experience with complex and RF PCBs

-

Quality management systems

-

Engineering communication efficiency

-

Delivery reliability and scalability

A reliable factory direct partner supports long-term business growth.

Conclusion

PCB factory direct manufacturing offers a clear advantage in pricing transparency, production efficiency, and quality assurance. By sourcing PCBs directly from the factory, companies gain better control over cost, lead time, and manufacturing quality.

Partnering with an experienced PCB factory direct manufacturer ensures reliable PCB production from prototype to mass production, supporting faster product development and long-term success.