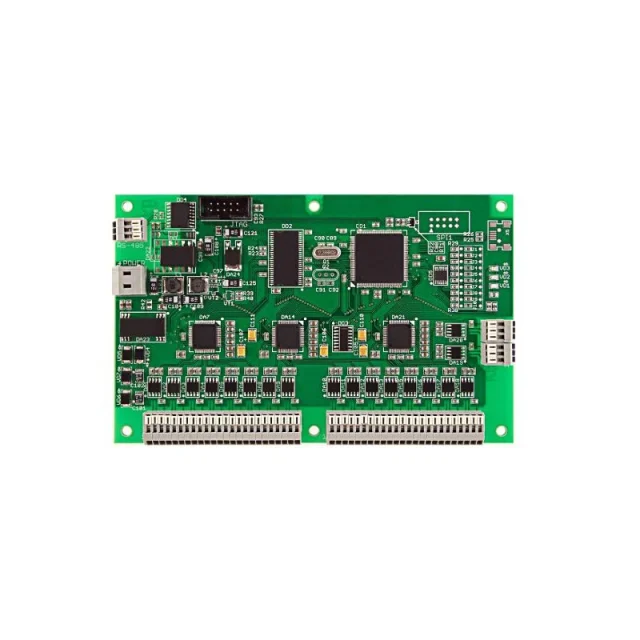

What Is OEM PCB?

An OEM PCB refers to a customized printed circuit board manufactured and assembled by a professional PCB supplier based on the customer’s design files and specifications. OEM PCB services typically cover PCB fabrication, PCB assembly, component sourcing, testing, and logistics, enabling customers to focus on product design and market development.

OEM PCB manufacturing is widely used by electronics brands, system integrators, startups, and OEM/ODM companies seeking reliable production partners.

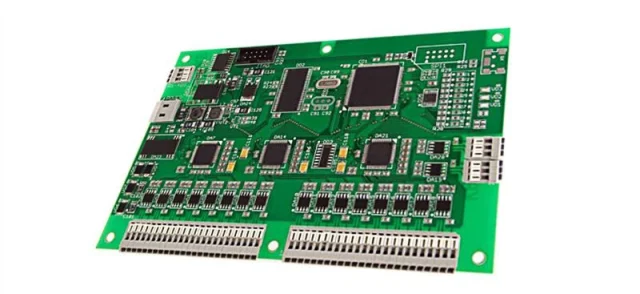

Scope of OEM PCB Services

A complete OEM PCB service usually includes:

-

PCB fabrication

Single-layer, multilayer, HDI, rigid-flex, heavy copper, ceramic, and low-loss PCBs. -

PCB assembly (PCBA)

SMT, THT, and mixed-technology assembly. -

Component sourcing

Active and passive components from authorized channels. -

Testing and inspection

AOI, X-ray, ICT, functional testing. -

Packaging and logistics

Customized packaging and global shipment support.

OEM PCB services can support prototype, small batch, and mass production.

Key Advantages of OEM PCB Manufacturing

Choosing a professional OEM PCB manufacturer offers several advantages:

-

Customized production based on customer designs

-

Cost optimization through manufacturing expertise

-

Stable quality and process consistency

-

Scalable production from prototype to volume

-

Reduced supply chain complexity

-

Faster time-to-market

OEM PCB manufacturing allows customers to turn designs into reliable products efficiently.

OEM PCB Manufacturing Capabilities

A qualified OEM PCB supplier typically supports:

-

Wide material selection

FR-4, high-Tg, low-loss, RF laminates, ceramic substrates. -

Advanced PCB structures

HDI, blind/buried vias, back drilling, hybrid stack-ups. -

Precision impedance control

-

Automotive and industrial-grade quality systems

-

Traceability and documentation support

These capabilities ensure reliable OEM PCB production.

Quality Control in OEM PCB Production

Quality is critical in OEM PCB manufacturing. Key quality measures include:

-

Incoming material inspection

-

Process control during fabrication and assembly

-

AOI and X-ray inspection

-

Electrical and functional testing

-

Reliability testing when required

Strict quality control ensures OEM PCBs meet customer and industry standards.

Applications of OEM PCB

OEM PCBs are widely used in:

-

Consumer electronics

-

Industrial control systems

-

Automotive electronics and ADAS

-

Telecommunication and networking equipment

-

Medical devices

-

Power electronics and energy systems

OEM PCB services support a wide range of electronic products.

OEM PCB vs ODM PCB

-

OEM PCB: Customer provides design; manufacturer focuses on production.

-

ODM PCB: Manufacturer provides both design and production.

OEM PCB offers greater design control and brand ownership for customers.

Conclusion

An OEM PCB service provides a reliable and scalable solution for transforming electronic designs into finished products. With comprehensive manufacturing capabilities, strict quality control, and flexible production volumes, OEM PCB manufacturing supports efficient product development and mass production.

Partnering with an experienced OEM PCB manufacturer ensures stable quality, optimized cost, and long-term production success.