In an increasingly competitive electronics market, shortening development cycles while maintaining product quality has become a major challenge for OEMs and system developers. ODM PCB services address this challenge by integrating PCB design, engineering validation, fabrication, and assembly into a single, efficient workflow.

By working with an experienced ODM PCB partner, companies can reduce coordination costs, minimize technical risks, and accelerate the transition from concept to mass production.

What Are ODM PCB Services?

ODM PCB (Original Design Manufacturer PCB) services go beyond traditional build-to-print manufacturing. Instead of simply producing boards from customer files, ODM PCB providers actively participate in the design and engineering process.

Typical ODM PCB services include:

-

PCB design and layout optimization

-

Stackup planning and material selection

-

Controlled impedance and signal integrity analysis

-

PCB fabrication and PCBA assembly

-

Prototype, small-batch, and volume production

This integrated approach ensures that designs are optimized for both performance and manufacturability from the earliest stage.

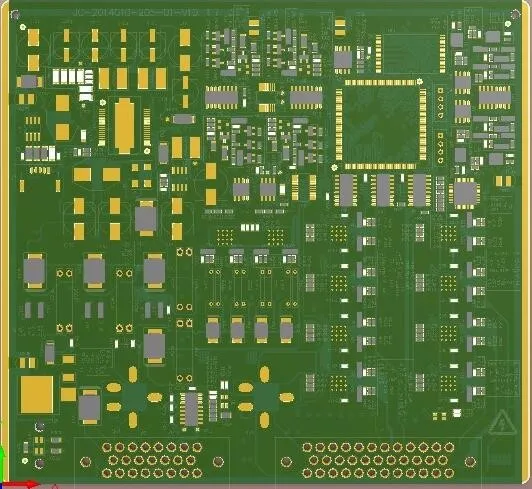

Engineering-Driven PCB Design Optimization

One of the core strengths of ODM PCB services is early engineering involvement. Design decisions made during the initial stage have a significant impact on cost, yield, and long-term reliability.

ODM PCB engineering support focuses on:

-

DFM, DFA, and DFT optimization

-

High-speed and RF signal integrity control

-

Power integrity and thermal management

-

HDI, high-layer-count, and rigid-flex PCB structures

By addressing these factors early, ODM PCB services reduce design iterations and improve first-pass success rates.

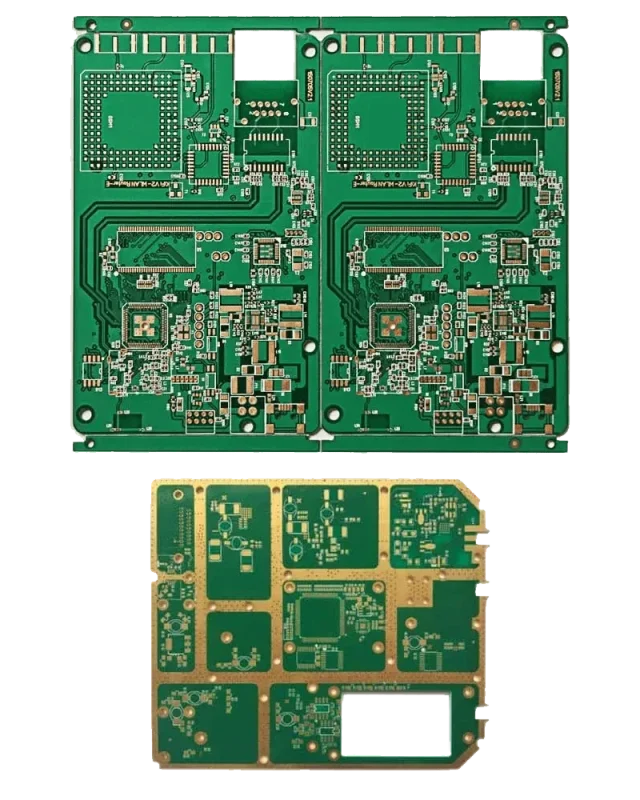

Rapid Prototyping and Small-Batch ODM PCB Manufacturing

ODM PCB services are especially valuable during the prototyping and pilot phases. Fast-turn prototypes allow engineers to validate performance and functionality before committing to large-scale production.

Benefits of ODM PCB prototyping include:

-

Faster design validation and debugging

-

Reduced development risk

-

Seamless transition from prototype to production

-

Consistent process control across all stages

Small-batch ODM PCB manufacturing supports engineering samples, internal testing, and customer qualification.

Material Selection and Advanced Stackup Solutions

ODM PCB projects often require advanced materials and customized stackups to meet electrical and environmental requirements.

Common ODM PCB material solutions include:

-

High-Tg FR-4 for standard and industrial applications

-

Low-loss laminates for high-speed and RF designs

-

Hybrid stackups combining RF and digital layers

-

Thermally stable materials for automotive and industrial electronics

Proper material selection ensures signal integrity, mechanical stability, and long-term reliability.

ODM PCB Assembly and Quality Control

ODM PCB services typically include full PCB assembly (PCBA), ensuring compatibility between design intent and manufacturing execution.

Assembly and quality control processes include:

-

SMT and selective assembly

-

AOI, X-ray inspection, and functional testing

-

Controlled impedance and electrical verification

-

Process monitoring for consistency and repeatability

This end-to-end control helps maintain high quality across prototype and production stages.

Scalable ODM PCB Manufacturing for Mass Production

Once the design is validated, ODM PCB services enable smooth scaling to volume production. Because the same team manages design data, materials, and manufacturing processes, consistency is maintained throughout the product lifecycle.

ODM PCB manufacturing advantages include:

-

Stable supply chain management

-

Repeatable process control

-

Reduced production risk and cost fluctuations

-

Long-term product support

This makes ODM PCB an ideal solution for products with long lifecycles and strict reliability requirements.

Why Choose an ODM PCB Partner

Choosing the right ODM PCB partner is critical for product success. A reliable ODM PCB provider offers:

-

Integrated design-to-manufacturing capabilities

-

Strong engineering communication and support

-

Faster time-to-market

-

Improved yield and quality consistency

-

Reduced coordination and sourcing complexity

ODM PCB services are especially suitable for OEMs developing complex, high-performance electronic systems.

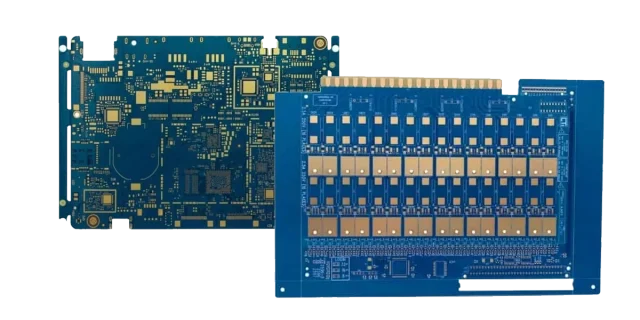

ODM PCB Services by KKPCB

KKPCB delivers professional ODM PCB services covering design support, rapid prototyping, fabrication, and assembly. With expertise in high-speed, RF, multilayer, and rigid-flex PCBs, KKPCB helps customers accelerate development while ensuring reliable, scalable production.

From concept engineering to mass production, KKPCB provides ODM PCB solutions tailored to your product requirements.