In today’s fast-evolving electronics market, speed, reliability, and manufacturability are just as critical as innovation. ODM PCB services bridge the gap between product concept and mass production by offering a fully integrated workflow that combines engineering design, PCB fabrication, and assembly under one roof.

Rather than managing multiple vendors for design, prototyping, and production, companies choose ODM PCB partners to streamline development, reduce technical risk, and accelerate commercialization.

What Is ODM PCB?

ODM PCB (Original Design Manufacturer PCB) refers to a turnkey solution where a single supplier is responsible for PCB design optimization, material selection, stackup planning, fabrication, and PCBA assembly. ODM PCB services are ideal for customers who need engineering support beyond simple build-to-print manufacturing.

ODM PCB is widely used in:

-

High-speed digital systems

-

RF and high-frequency electronics

-

Automotive and industrial control

-

Semiconductor testing and ATE systems

-

IoT, communication, and embedded hardware

Engineering-Focused ODM PCB Design

A key advantage of ODM PCB is early-stage engineering involvement. By addressing manufacturability and signal integrity at the design phase, ODM PCB significantly improves first-pass yield and long-term reliability.

ODM PCB engineering capabilities include:

-

Controlled impedance PCB design

-

High-speed signal integrity optimization

-

RF and microwave layout support

-

HDI and high-layer-count PCB planning

-

Rigid-flex and mixed-material stackups

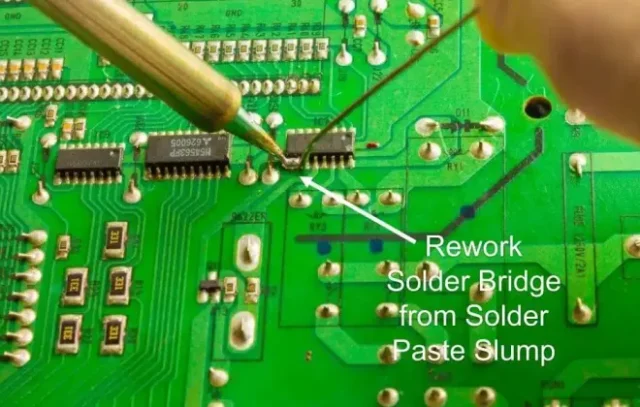

Through DFM, DFA, and DFT analysis, ODM PCB ensures the design is optimized not only for performance but also for stable mass production.

ODM PCB Materials and Stackup Expertise

ODM PCB projects often require advanced materials and hybrid constructions. A professional ODM PCB partner provides guidance on selecting the right laminates to balance performance, cost, and availability.

Common ODM PCB materials include:

-

FR-4 for standard digital and control boards

-

Rogers, Taconic, and PTFE for RF and high-frequency PCB

-

Hybrid stackups combining low-loss RF cores with standard FR-4

-

High-Tg and low-CTE materials for automotive and industrial use

Material selection is tightly integrated with impedance modeling and thermal management in ODM PCB workflows.

Prototyping and Small-Batch ODM PCB Manufacturing

ODM PCB services are especially valuable during prototyping and pilot production stages. Fast-turn ODM PCB prototypes allow engineering teams to validate designs quickly before scaling to volume.

ODM PCB prototype advantages:

-

Rapid PCB layout revision and optimization

-

Small-batch PCB fabrication and PCBA

-

Electrical testing and functional verification

-

Smooth transition from prototype to mass production

This approach minimizes redesign cycles and shortens overall development timelines.

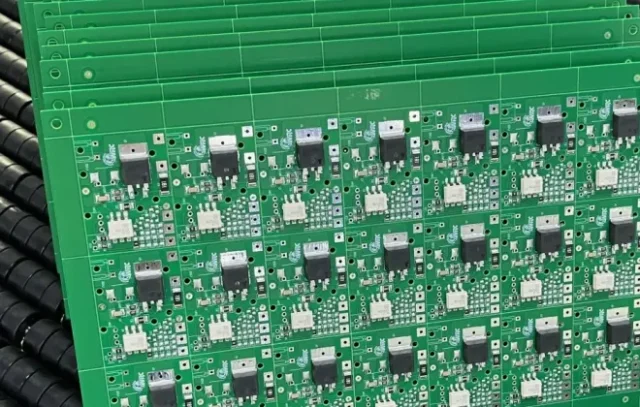

ODM PCB for Mass Production and Long-Term Supply

Once validated, ODM PCB designs are seamlessly transferred into volume manufacturing. Because the same team controls design data, materials, and process parameters, ODM PCB ensures consistency and quality throughout the product lifecycle.

ODM PCB production capabilities typically include:

-

Automated SMT and selective assembly

-

AOI, X-ray, and in-circuit testing

-

Process-controlled impedance and thickness monitoring

-

Stable supply chain and lifecycle management

This makes ODM PCB ideal for long-term projects requiring reliability and scalability.

Why Choose an ODM PCB Partner

Selecting the right ODM PCB partner is not just about cost—it is about engineering collaboration and manufacturing reliability.

An experienced ODM PCB supplier offers:

-

One-stop design-to-production service

-

Reduced engineering and sourcing risk

-

Faster time-to-market

-

Improved yield and cost control

-

Strong technical communication and support

ODM PCB partnerships are especially valuable for startups, system integrators, and OEMs developing complex electronic platforms.

ODM PCB Solutions by KKPCB

KKPCB provides professional ODM PCB services covering design support, prototyping, fabrication, and assembly for high-reliability electronic applications. With expertise in high-speed, RF, rigid-flex, and multilayer PCB manufacturing, KKPCB helps customers bring innovative designs to market faster and more reliably.

Whether you need a proof-of-concept prototype or scalable ODM PCB manufacturing, KKPCB delivers engineering-driven solutions tailored to your product requirements.