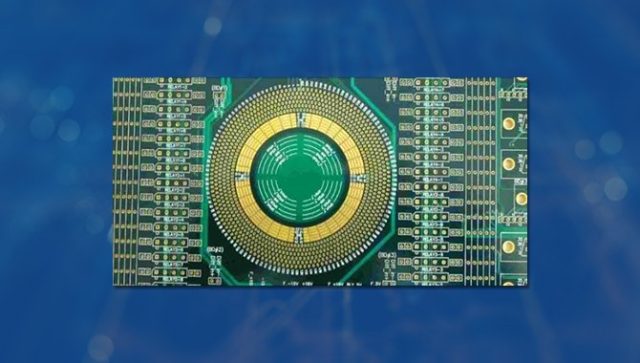

What Is a Load Board PCB?

A Load Board PCB is a printed circuit board used to simulate real-world electrical loads and interface electronic devices with automated test equipment (ATE). Load boards allow engineers to test ICs, modules, and systems under controlled conditions, ensuring functional correctness and reliability before mass production.

Unlike standard PCBs, Load Board PCBs are designed to handle high current, frequent test cycles, and precise signal routing.

Key Design Requirements for Load Board PCB

Designing a high-performance Load Board PCB requires careful attention:

-

High-current trace routing

Supports repeated test cycles without overheating. -

Thermal management

Copper planes or metal-core substrates dissipate heat effectively. -

Precision signal paths

Ensures accurate measurement and minimal signal distortion. -

Durable test points

Withstands repeated probe contact and insertion/removal cycles. -

Stable electrical performance

Maintains consistent results under various test conditions.

These design principles ensure reliable and repeatable testing.

Materials and Manufacturing

Load Board PCBs often require specialized materials:

-

High-temperature FR-4 laminates

For moderate current and thermal stress. -

Metal-core PCBs

For high-power or high-current applications. -

Ceramic or hybrid materials

Provide excellent thermal stability for precise testing.

Manufacturing considerations include:

-

Thick copper layers and robust vias

To handle high currents. -

Accurate layer registration and lamination

Ensures dimensional stability. -

Surface finish options

ENIG, hard gold, or immersion silver for reliable probe contact. -

Electrical and functional testing

Guarantees consistent performance before delivery.

Advantages of Using Load Board PCB

-

Accurate and repeatable testing of electronic devices.

-

Early detection of failures, reducing production risks.

-

Support for high-current and high-density designs.

-

Improved reliability and product quality.

-

Compatibility with automated test equipment for efficient production testing.

Load Board PCBs are critical for quality assurance and R&D testing.

Applications of Load Board PCB

Load Board PCBs are used in:

-

Semiconductor IC and chip testing

-

Automated test equipment (ATE)

-

High-power module validation

-

Consumer electronics functional testing

-

Automotive and industrial electronics stress testing

They are widely adopted wherever accurate and reliable device testing is required.

Conclusion

A Load Board PCB is an essential component for electronic testing, validation, and quality assurance. By combining high-current handling, precise signal routing, and durable design, Load Board PCBs provide engineers with reliable test results and reduce production risks.

Partnering with an experienced Load Board PCB manufacturer ensures high-quality boards capable of supporting repeated testing cycles and demanding electrical conditions.