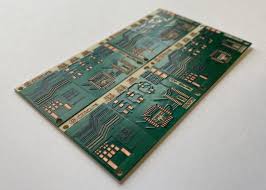

High-power LED systems require extreme reliability, efficient heat spreading, and stable electrical performance across thousands of thermal cycles. Alumina PCB, Alumina Ceramic PCB, and Al₂O₃ PCB substrates have become the preferred materials for LED lighting modules due to their high thermal conductivity, mechanical stability, and superior dielectric strength.

1. Heat Dissipation for High-Power LED Packages

LED efficiency and lifespan are directly tied to operating temperature.

Alumina Ceramic PCB substrates offer thermal conductivity between 20–30 W/m·K, enabling rapid heat extraction from LED junctions.

Compared with FR-4 or metal-core PCB platforms, Alumina PCB solutions maintain dramatically lower junction temperatures.

This improves:

-

Luminous stability

-

Chromatic accuracy

-

Long-term lumen maintenance

-

Prevention of thermal runaway

Al₂O₃ PCB materials ensure that LED arrays can operate at their intended brightness without accelerated degradation.

2. Temperature Cycling Endurance for Harsh Environments

High-power LED modules often face rapid thermal swings during start-stop cycles, outdoor temperature fluctuations, or high-intensity pulsing.

The crystalline ceramic structure of Alumina PCB substrates withstands repetitive expansion-contraction cycles without micro-cracking.

This endurance prevents:

-

Metallization delamination

-

Via fatigue

-

Solder joint failure

-

Optical output instability

As a result, Alumina Ceramic PCB technology is widely deployed in automotive headlights, industrial floodlights, smart city lighting, and aerospace illumination systems.

3. Electrical Stability and High-Voltage Isolation

High-power LED drivers may require elevated operating voltages, especially in multi-series LED strings.

Al₂O₃ PCB substrates provide strong dielectric isolation, ensuring safe separation between the LED drive circuitry and the aluminum heatsink or metal housing.

The high dielectric strength of Alumina Ceramic PCB materials eliminates leakage current, prevents tracking, and improves reliability in moisture-rich or polluted environments.

4. Mechanical Strength for Outdoor and Industrial LED Lighting

Outdoor LED systems encounter vibrations, wind loading, thermal shock, and mechanical stress.

Alumina PCB technology maintains structural integrity due to its high flexural strength and resistance to brittle fracture.

This mechanical durability contributes to:

-

Stable optical alignment

-

Long-term LED solder joint integrity

-

Superior reliability in high-mount lighting installations

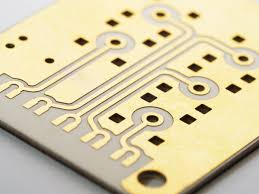

5. Metallization and Packaging Options on Alumina PCB

Alumina Ceramic PCB substrates support thick-film and thin-film metallization using Ag-Pt, Ag-Pd, Au, and W-based conductor systems.

These materials ensure strong adhesion, high current handling, and long-term oxidation resistance.

Combined with selective gold plating and high-reflectivity coatings, Al₂O₃ PCB platforms improve both electrical efficiency and optical extraction efficiency in LED modules.

Conclusion

Alumina PCB, Alumina Ceramic PCB, and Al₂O₃ PCB solutions deliver unparalleled temperature cycling endurance, heat dissipation capability, mechanical stability, and dielectric performance for high-power LED arrays.

These properties make Alumina substrates essential for automotive lighting, industrial illumination, aerospace beacons, and mission-critical LED systems that must perform reliably for tens of thousands of hours.