What Are High TG Materials?

High TG materials refer to PCB laminate materials with a high glass transition temperature (Tg), typically above 170°C and often reaching 180°C–200°C or higher.

The Tg value indicates the temperature at which the PCB material transitions from a rigid glass-like state to a softer rubber-like state. Using high TG materials ensures better thermal stability and mechanical reliability under elevated temperature conditions.

High TG materials are widely used in:

-

Automotive electronics

-

Industrial control systems

-

Power electronics

-

High layer count PCB

-

High reliability PCB

-

Lead-free assembly processes

Why High TG Materials Are Important

Modern electronic systems generate more heat due to higher power density and compact designs. Standard FR-4 materials may suffer from:

-

Delamination

-

Warpage

-

Barrel cracking

-

Reduced mechanical strength

-

Poor long-term reliability

High TG materials improve:

-

Thermal resistance

-

Mechanical stability

-

Chemical resistance

-

Moisture resistance

-

Long-term performance under thermal cycling

For high reliability PCB and high temperature PCB applications, high TG materials are essential.

Key Properties of High TG Materials

High Glass Transition Temperature

Typically ≥170°C, improving dimensional stability during soldering and reflow.

Improved Thermal Stability

Better performance under multiple lead-free soldering cycles.

Lower Z-Axis Expansion

Reduced risk of via cracking in multilayer PCB designs.

Enhanced Mechanical Strength

Better resistance to warpage and mechanical stress.

High TG Materials vs Standard FR-4

| Feature | High TG Materials | Standard FR-4 |

|---|---|---|

| Tg Value | ≥170°C | 130°C–150°C |

| Thermal Stability | Excellent | Moderate |

| Lead-Free Compatibility | Excellent | Limited |

| Reliability in Harsh Environment | High | Moderate |

For automotive PCB, industrial PCB, and high power PCB applications, high TG materials provide significantly improved durability.

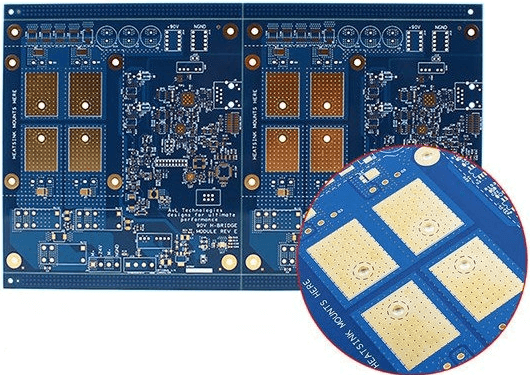

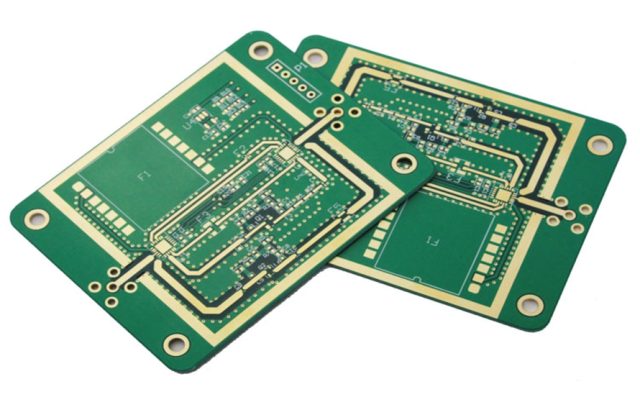

Applications of High TG Materials

High TG materials are commonly used in:

-

Automotive control modules

-

EV power systems

-

Industrial automation PCB

-

High layer count PCB

-

High current PCB

-

Server and networking PCB

-

Power supply PCB

-

LED driver PCB

When thermal stress and reliability are critical, high TG materials offer long-term stability.

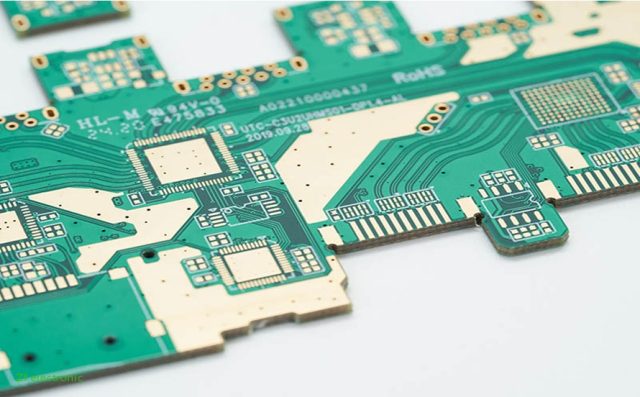

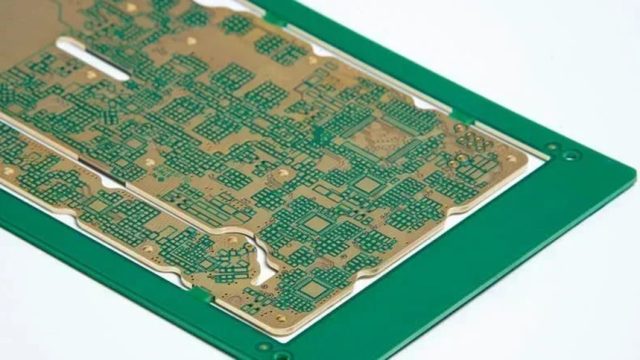

Manufacturing Considerations

PCB fabrication with high TG materials requires:

-

Controlled lamination temperature

-

Precise drilling and plating

-

Proper resin flow control

-

Moisture management

-

Strict process monitoring

Using high TG materials also improves multilayer PCB yield and reduces failure risks during assembly.

Choosing the Right High TG PCB Supplier

A professional high TG PCB supplier should provide:

-

Multiple high TG laminate options

-

High layer count PCB capability

-

Controlled impedance support

-

Automotive-grade PCB manufacturing

-

Stable quality control systems

Selecting high TG materials ensures durability, reliability, and consistent performance in demanding applications.