In high-speed wireless systems, radar, 5G networks, and other advanced electronic products, selecting the right high frequency PCB supplier is critical to ensure signal integrity, minimize losses, and achieve reliable performance. Unlike standard PCB manufacturing, high frequency PCB production demands tight material control, precise impedance management, and advanced fabrication technology.

This article provides a comprehensive guide to help engineers and procurement teams evaluate and choose the best high frequency PCB supplier for RF and microwave applications.

What Is a High Frequency PCB Supplier?

A high frequency PCB supplier is a manufacturer capable of producing PCBs designed for high-frequency and RF applications. These boards typically operate at gigahertz (GHz) or higher frequencies and require:

-

Low dielectric constant (Dk) and dissipation factor (Df)

-

Stable electrical and thermal properties

-

Tight impedance control and minimal signal loss

-

Advanced manufacturing and quality control processes

Choosing a supplier with proven high frequency PCB expertise is essential to delivering designs that meet performance expectations.

Key Considerations When Choosing a High Frequency PCB Supplier

1. Material Expertise

The right high frequency PCB supplier must be proficient in handling specialized materials such as:

-

Rogers laminates: Known for stable dielectric properties and low loss

-

PTFE-based materials: Ideal for ultra-high frequency and microwave applications

-

Hybrid stackups: Combining advanced RF materials with FR-4 for cost-effective solutions

Material selection directly affects signal quality, impedance stability, and manufacturing yield.

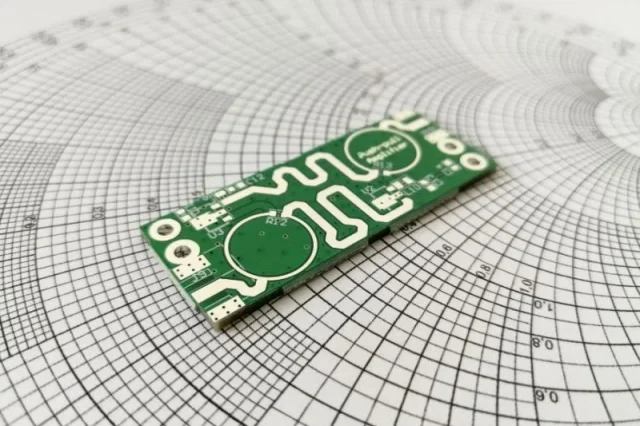

2. Impedance Control Capability

Impedance control is fundamental in high frequency PCB design and manufacturing. The supplier should demonstrate:

-

Accurate impedance modeling and control

-

Tight tolerance capabilities (e.g., ±5%, ±10%)

-

Test coupons and TDR (Time Domain Reflectometry) validation processes

Strong impedance control capability ensures predictable signal behavior and improved overall system performance.

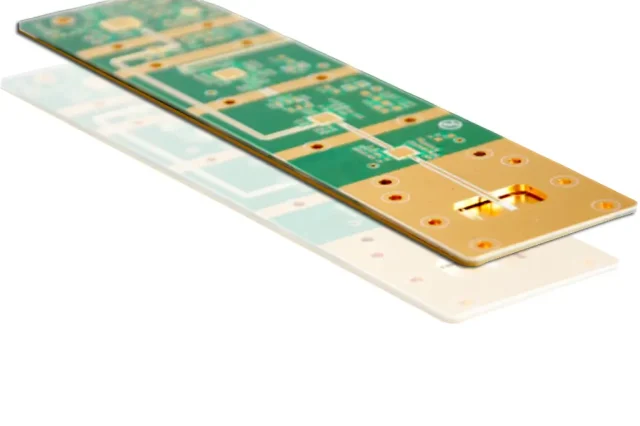

3. Advanced Manufacturing Processes

A qualified high frequency PCB supplier should offer advanced fabrication capabilities, including:

-

Precise lamination and etching

-

Fine line width and spacing control

-

RF-specific inspection and testing

-

Stable multilayer stackup processes

These capabilities are critical for high performance RF and microwave PCB production.

Quality Assurance and Testing

Reliable suppliers implement rigorous quality assurance processes such as:

-

TDR impedance testing

-

Network analysis for RF integrity

-

AOI and X-ray inspection

-

Thermal and environmental stress testing

These testing methods ensure that the finished boards meet electrical and reliability criteria before delivery.

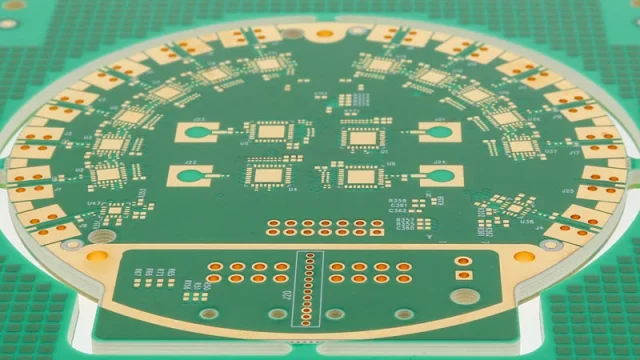

Real-World Applications of High Frequency PCBs

High frequency PCBs are widely used in:

-

RF front-end modules

-

5G and wireless communication systems

-

Radar and satellite electronics

-

Automated driver-assist systems (ADAS)

-

Aerospace and defense electronics

In each of these fields, selecting a capable high frequency PCB supplier enhances performance and reduces development risk.

Conclusion

Choosing the right high frequency PCB supplier requires careful evaluation of material expertise, impedance control capability, manufacturing processes, and QA/testing procedures. A reliable supplier ensures stable performance, consistent quality, and seamless transition from prototype to volume production.

Partner with a trusted high frequency PCB manufacturer to ensure your RF and microwave designs achieve exceptional performance and long-term reliability.