In today’s highly competitive electronics market, speed is often the key differentiator between success and missed opportunity. Fast delivery PCB services enable engineers, startups, and OEMs to shorten development cycles, validate designs faster, and respond quickly to market demands.

Whether for early-stage prototypes, small-batch production, or urgent engineering revisions, fast delivery PCB manufacturing plays a critical role in modern electronic product development.

What Is Fast Delivery PCB?

Fast delivery PCB refers to rapid-turn PCB fabrication and assembly services designed to minimize lead time without compromising quality or reliability. Unlike standard PCB production, fast delivery PCB focuses on:

-

Shortened manufacturing cycles

-

Priority engineering review

-

Optimized process flow

-

Immediate material readiness

Fast delivery PCBs are commonly delivered within 24–72 hours for prototypes and within a few days for small-batch production, depending on complexity.

Why Fast Delivery PCB Matters?

Accelerated Product Validation

Fast delivery PCB allows engineers to quickly verify circuit functionality, signal integrity, and thermal performance. Faster prototypes mean faster design decisions.

Reduced Time-to-Market

For startups and OEMs, fast delivery PCB shortens development timelines and enables earlier product launches.

Efficient Engineering Iteration

Design issues can be identified and corrected quickly, reducing costly delays in later production stages.

Support for Urgent Projects

Fast delivery PCB is ideal for urgent customer demands, last-minute design changes, or time-critical testing schedules.

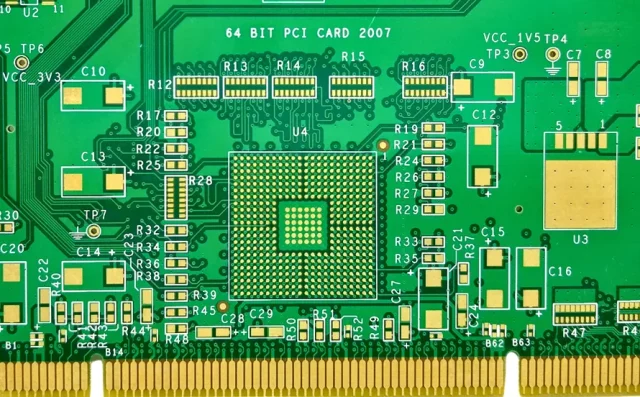

Key Capabilities of Fast Delivery PCB Manufacturing

A professional fast delivery PCB supplier must balance speed with precision. Core capabilities include:

-

Rapid DFM and engineering review

-

Quick-turn multilayer PCB fabrication

-

Controlled impedance and tight tolerance processing

-

HDI and high pin count PCB support

-

Fast delivery PCB assembly (SMT & THT)

These capabilities ensure that even complex boards can be delivered quickly and reliably.

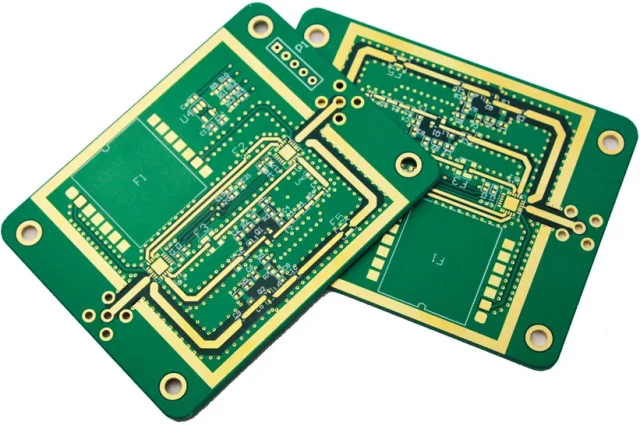

Fast Delivery PCB for Prototypes and Small Batches

Fast delivery PCB services are especially valuable during the prototype and pilot stages.

Typical applications include:

-

New product development (NPD)

-

High-speed and RF PCB prototyping

-

ATE and semiconductor test PCB

-

Automotive and industrial control boards

-

IoT and communication modules

Small-batch fast delivery PCB manufacturing allows teams to validate performance before scaling to mass production.

Materials and Technologies in Fast Delivery PCB

To ensure both speed and performance, fast delivery PCB manufacturers commonly support:

-

Standard and high-Tg FR-4 materials

-

Controlled impedance stackups

-

HDI structures with microvias

-

Multilayer PCBs up to high layer counts

-

Select low-loss materials for high-speed designs

Material availability and process optimization are critical to achieving fast delivery without quality trade-offs.

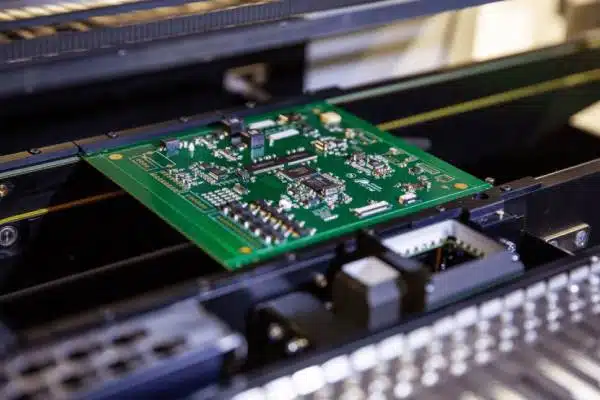

Quality Control in Fast Delivery PCB

Speed should never come at the expense of reliability. High-quality fast delivery PCB production includes:

-

Automated optical inspection (AOI)

-

Electrical testing and continuity checks

-

Impedance verification when required

-

Process control for thickness and registration

These steps ensure that fast delivery PCBs meet performance and reliability requirements, even under tight timelines.

Choosing the Right Fast Delivery PCB Partner

When selecting a fast delivery PCB supplier, consider the following factors:

-

Proven quick-turn manufacturing experience

-

Strong engineering support and communication

-

Capability for both PCB fabrication and assembly

-

Stable material supply and in-house process control

-

Ability to scale from fast prototype to volume production

A reliable partner ensures speed, consistency, and long-term manufacturability.

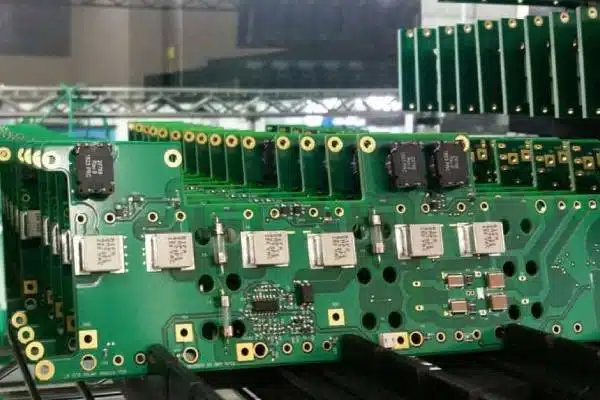

Fast Delivery PCB Solutions by KKPCB

KKPCB provides professional fast delivery PCB services, supporting rapid prototyping, small-batch production, and time-critical projects. With advanced fabrication capabilities, in-house engineering support, and strict quality control, KKPCB helps customers accelerate product validation and shorten development cycles.

From fast delivery PCB prototypes to scalable manufacturing, KKPCB delivers speed without sacrificing quality.