Achieving Traceable Phase Accuracy and Long-Term Measurement Repeatability Through KKPCB’s RF Metrology Manufacturing Framework

1. Context — Why Measurement Stability Defines Modern RF Metrology

In advanced calibration systems, such as Vector Network Analyzers (VNA), antenna test chambers, and satellite link verification benches, the PCB substrate becomes the reference plane of accuracy.

Even a 0.05 variation in Dk or a 0.1 dB amplitude imbalance can distort calibration constants across the full signal path—affecting every subsequent measurement.

Duroid 5880, with its ultra-low dielectric constant (Dk = 2.20 ± 0.02) and dissipation factor of 0.0009, is widely adopted in precision RF fixtures due to its linear dielectric response up to 110 GHz.

However, ensuring consistent electrical behavior across multiple production lots and environmental conditions requires a controlled, traceable, and repeatable process chain—one that KKPCB’s RF metrology platform was engineered to deliver.

2. The Challenge — Translating Material Purity Into System-Level Accuracy

Even though Duroid 5880 provides excellent dielectric stability, in real metrology systems it faces compound mechanical and electrical stresses:

| Engineering Challenge | Root Cause | Measurement Impact |

|---|---|---|

| Dk variation across lot | Glass microfibre orientation / moisture content | Calibration phase drift |

| Surface roughness inconsistency | Copper foil Ra deviation | Insertion loss variation |

| Micro-delamination | Lamination voids during multiple thermal cycles | Reference plane instability |

| Phase imbalance between channels | CTE mismatch during operation | Differential skew in multi-port VNA calibration |

KKPCB’s approach focuses on controlling every variable that could alter the phase stability and calibration repeatability of precision RF fixtures.

3. KKPCB’s Controlled Dielectric Process Framework

3.1 Material Conditioning & Pre-Processing

-

All Duroid 5880 panels are pre-baked at 120 °C for 4 h in vacuum to eliminate moisture and volatile outgassing.

-

Dielectric constant mapping (20 × 20 cm grid) ensures ±0.01 uniformity prior to layup.

-

Each batch’s Dk/Df verified via split-post resonator test at 10 GHz.

3.2 Precision Lamination Control

-

175 °C / 200 psi vacuum lamination, with controlled cooling rate < 1.5 °C/min to minimize resin stress.

-

Interlayer dielectric thickness controlled within ± 8 µm tolerance.

-

Low-profile RA copper (Ra < 0.8 µm) applied to minimize phase ripple above 90 GHz.

3.3 Metrology-Grade Validation

-

Inline VNA & TDR verification up to 110 GHz across test coupons.

-

S-parameter deviation between test lots maintained within 0.05 dB / 0.5°.

-

All data stored in KKPCB’s traceable quality archive, enabling calibration reproducibility.

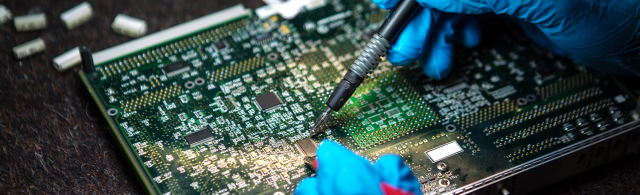

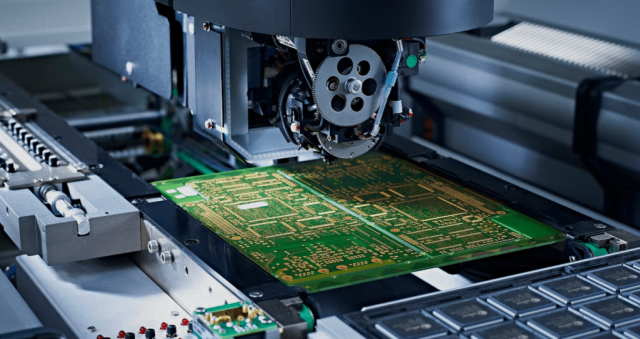

RO5880 PCB

4. Case Study — 67 GHz Multi-Port VNA Calibration Subsystem

Client: European measurement equipment OEM

Application: High-precision 67 GHz calibration module for multi-channel test bench

Objective: Ensure phase-locked repeatability across 8 ports within ±0.5°

Engineering Pain Points

-

Previous FR-PTFE hybrids exhibited phase nonlinearity during 85°C operation, corrupting calibration coefficients.

-

Repeated connector insertions led to microscopic delamination near microstrip edges, increasing S11.

KKPCB Engineering Solution

-

Transitioned to Duroid 5880 double-layer core with low-flow PTFE bond film (CTE_z < 15 ppm/°C).

-

Integrated in-pad thermal vias under connector pads to reduce localized heating.

-

Added 3D EM compensation to preserve phase linearity above 60 GHz.

-

Implemented inline Dk verification and VNA traceability protocol during production.

| Parameter | Before KKPCB Process | After KKPCB Process |

|---|---|---|

| Dk uniformity | ±0.04 | ±0.01 |

| Phase drift (50–67 GHz) | 1.6° | 0.4° |

| Insertion loss deviation | 0.18 dB | 0.06 dB |

| Connector endurance (500 cycles) | 4 % failure | < 0.5 % failure |

Result: The system achieved a 30 % longer calibration retention period, with traceable dielectric consistency across all modules—allowing the OEM to align multi-site calibration results within ±0.2 dB globally.

5. Environmental Endurance & Reliability Verification

KKPCB performs rigorous reliability and calibration retention tests for all Duroid 5880-based precision boards:

| Test Type | Condition | Result |

|---|---|---|

| Thermal cycling | –55 °C ↔ +150 °C / 1000 cycles | No Dk drift or layer delamination |

| Humidity aging | 85 °C / 85 % RH / 1000 h | Df increase < 0.00005 |

| Power endurance | 10 W/cm² @ 40 GHz | Stable amplitude ± 0.05 dB |

| Mechanical stress | > 500 connector cycles | No via cracking or resonance shift |

6. Engineering Insights — The Dielectric-to-Calibration Continuum

A metrology-grade PCB isn’t only defined by its low loss, but by its predictable behavior under all test conditions.

KKPCB’s production discipline transforms Duroid 5880’s material potential into repeatable, traceable calibration stability by:

-

Maintaining moisture-free pre-lamination to stabilize dielectric constant.

-

Enforcing tight copper profile control for predictable insertion loss.

-

Conducting lot-to-lot Dk/Df verification tied to RF metrology data.

-

Simulating thermal expansion and phase drift through EM co-simulation.

This closed-loop process ensures that each Duroid 5880 PCB functions as a consistent measurement reference, not merely as a substrate.

7. Conclusion — KKPCB’s Role in Precision RF Calibration Reliability

Duroid 5880 PCBs are the foundation of modern calibration systems operating above 50 GHz.

However, maintaining dielectric consistency and phase integrity across thermal and mechanical stresses requires engineering beyond materials.

KKPCB’s metrology manufacturing platform provides:

-

Controlled dielectric uniformity across full lot runs,

-

In-process Dk and phase verification to 110 GHz, and

-

Full traceability for global calibration equivalence.

-

With KKPCB, precision measurement equipment manufacturers gain phase-locked, repeatable, and verifiable dielectric stability—transforming Duroid 5880 from a high-performance material into a metrology-grade standard for RF calibration reliability.