As electronic systems operate at ever-higher frequencies, performance margins become increasingly narrow. When sourcing high frequency PCBs for radar, aerospace, and other high-reliability electronics, precision stackup engineering is no longer optional—it is essential. Engineers and purchasing teams must work with PCB manufacturers capable of delivering controlled impedance, low signal loss, and consistent layer-to-layer accuracy.

This article explains why precision stackup engineering matters and what to consider when buying high frequency PCBs for mission-critical applications.

Why Precision Stackup Engineering Matters in High Frequency PCBs

At high frequencies, even small variations in dielectric thickness, copper weight, or material properties can cause significant impedance mismatch and signal degradation. Precision stackup engineering ensures:

-

Accurate impedance control

-

Predictable signal propagation

-

Minimal insertion loss and reflection

-

Stable performance across production batches

For radar and aerospace systems, where reliability and accuracy are critical, stackup precision directly impacts system performance and safety.

Material Selection for High Frequency PCB Stackups

When you buy high frequency PCBs, material selection is a key part of stackup engineering. Common high-frequency materials include:

-

Rogers laminates (RO4003, RO4350, RO3003, RO5880)

-

PTFE-based materials for ultra-low loss applications

-

Taconic RF materials for microwave and mmWave designs

-

Hybrid stackups combining RF materials with FR-4

Selecting the right dielectric materials ensures stable Dk/Df values and long-term electrical reliability.

Impedance Control and Layer Design

Precision stackup engineering allows manufacturers to tightly control impedance for:

-

Microstrip and stripline structures

-

Differential pair routing

-

RF transmission lines and antenna feeds

Controlled impedance tolerances (typically ±5% or tighter) reduce signal distortion and ensure consistent performance in high frequency environments.

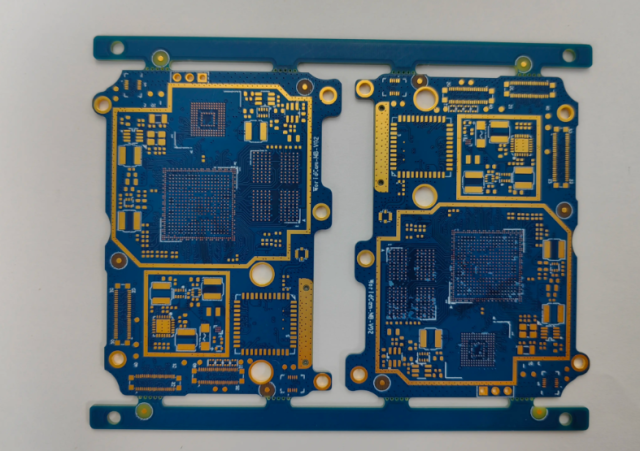

Manufacturing Accuracy for High-Reliability Applications

High frequency PCBs used in radar and aerospace applications demand advanced manufacturing capabilities, including:

-

Tight control of dielectric thickness and copper roughness

-

Precision lamination and etching processes

-

Accurate registration for multilayer boards

-

RF-specific testing such as TDR and insertion loss measurement

Manufacturers with these capabilities deliver high frequency PCBs that meet strict reliability standards.

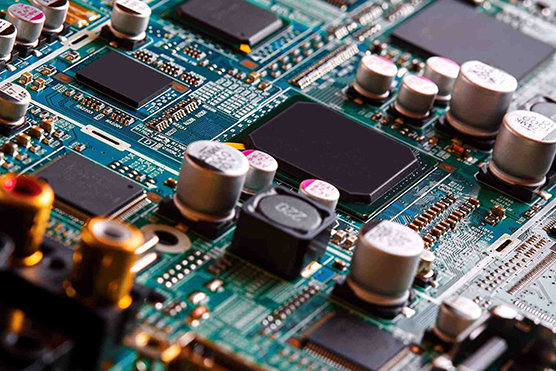

Applications Requiring Precision Stackup High Frequency PCBs

High frequency PCBs with precision stackup engineering are widely used in:

-

Radar and sensing systems

-

Aerospace and defense electronics

-

Satellite communication equipment

-

High-reliability RF modules

-

Advanced industrial and military electronics

In these applications, consistent electrical performance and manufacturing stability are mandatory.

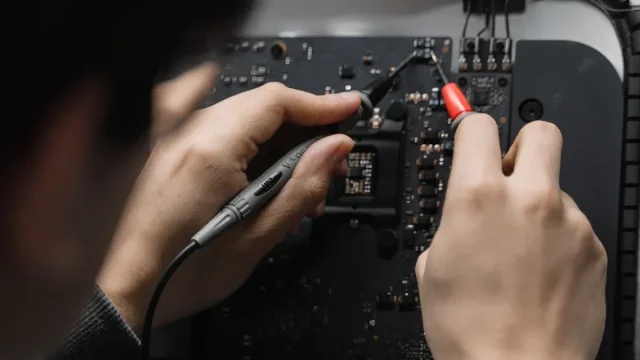

How to Choose the Right High Frequency PCB Supplier

When buying high frequency PCBs, look for suppliers that offer:

-

Stackup design and engineering support

-

Experience with RF and microwave materials

-

Proven impedance control capability

-

Reliable quality assurance and testing

-

Support from prototype to mass production

A qualified supplier ensures that your high frequency PCBs meet both electrical and reliability requirements.

Conclusion

To buy high frequency PCBs for radar, aerospace, and high-reliability electronics, precision stackup engineering is critical. From material selection and impedance control to manufacturing accuracy and testing, every detail affects performance.

Partnering with an experienced high frequency PCB manufacturer ensures consistent quality, reliable performance, and confidence in even the most demanding applications.