Automotive PCBs: The Backbone of Modern Vehicle Electronics

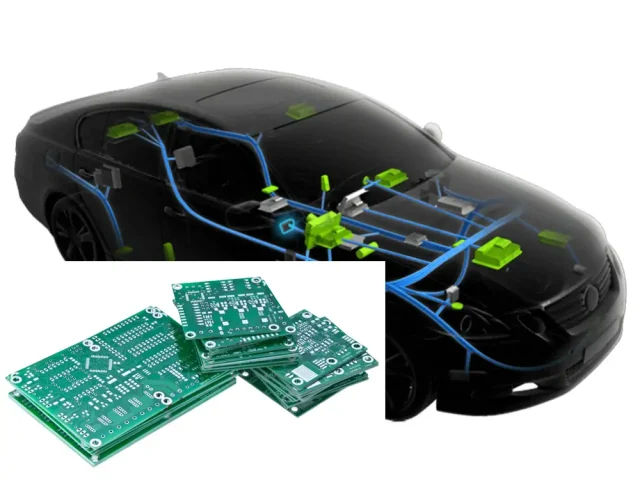

Printed Circuit Boards (PCBs) are fundamental to contemporary electronics, providing the structural foundation and electrical interconnections required by a wide range of components. Within the automotive industry, PCBs play an indispensable role—enabling everything from basic vehicle functions to advanced driver-assistance systems (ADAS) and electrification technologies.

Automotive PCBs must endure extreme vibration, fluctuating temperatures, humidity, and harsh chemicals. Therefore, they are manufactured to the highest reliability standards, commonly meeting IPC Class 3 or above. As vehicles continue to evolve toward greater intelligence, electrification, and connectivity, the importance of robust, automotive-grade PCBs has never been greater.

What Are Automotive PCBs?

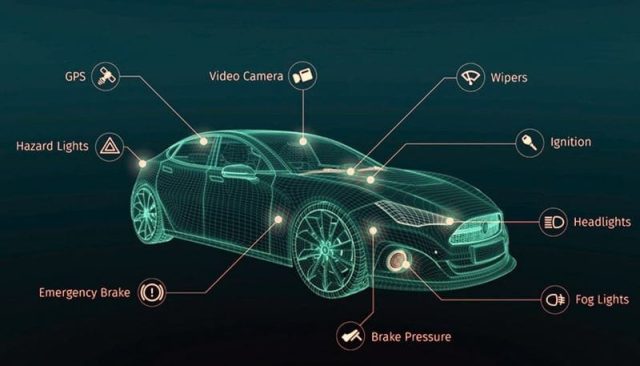

Automotive PCBs are specialized circuit boards engineered specifically for automotive electronic systems. They serve as the central platform for mounting and electrically connecting components that control crucial vehicle functions such as:

-

Engine ignition

-

Navigation systems

-

Headlight controls

-

Safety systems

-

Infotainment

-

ADAS sensors and modules

These PCBs must withstand:

-

High vibration

-

Wide temperature ranges

-

Chemical exposure

-

Moisture and dust

-

Long operating lifecycles (10–20 years)

They are designed to remain stable and fully functional even under the harshest automotive conditions, maintaining safety and reliability throughout the vehicle’s lifespan.

Common Types of Automotive PCBs

Automotive electronics require various PCB types, each serving different functional and environmental needs.

1. Rigid FR4 PCBs

-

Most widely used in automotive electronics

-

Excellent electrical and mechanical performance

-

Cost-effective and suitable for general control and communication modules

2. Aluminum PCBs

-

High thermal conductivity

-

Ideal for automotive LED lighting systems

-

Cost-efficient thermal management

3. Flexible PCBs

-

Bendable, lightweight, and ideal for limited-space applications

-

Perfect for cameras, dashboard systems, and foldable or vibration-prone areas

4. Rigid-Flex PCBs

-

Combine rigidity and flexibility

-

Enable 3D routing designs for highly compact automotive modules

-

Used in ADAS, connectivity modules, and advanced infotainment systems

Materials Commonly Used in Automotive PCBs

The choice of PCB materials directly impacts reliability, heat resistance, and long-term stability.

FR-4

-

Excellent balance of mechanical strength and cost

-

Suitable for engine control units, dashboards, and body electronics

Aluminum

-

Used in LED headlights and brake lights

-

Enhances heat dissipation and improves LED lifespan

Polyimide

-

Withstands high heat and vibration

-

Used in flexible and rigid-flex PCBs within tight or movable spaces

Applications of Automotive PCB Services

Modern vehicles rely heavily on PCBs to support essential and advanced functionalities.

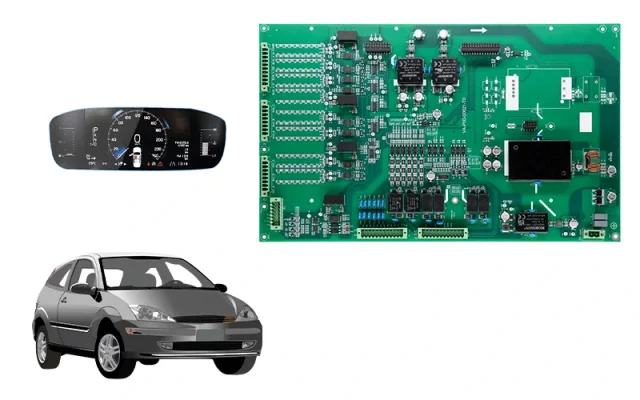

Engine Control Units (ECUs)

PCBs in ECUs manage:

-

Fuel injection

-

Ignition timing

-

Emission control

Ensuring optimal efficiency and reducing environmental impact.

Infotainment & Navigation Systems

Automotive PCBs enable:

-

Touchscreen control

-

Multimedia streaming

-

GPS navigation

-

Bluetooth and wireless communication

Safety Systems

Safety-critical PCBs are used in:

-

Airbag controllers

-

Anti-lock braking systems (ABS)

-

Stability control modules

The responsiveness and accuracy of these systems rely heavily on PCB reliability.

Intelligent & High-Tech Vehicle Systems

Emerging automotive technologies require more advanced PCBs, such as:

-

Autonomous driving modules

-

IoT and connected-car systems

-

Radar/lidar sensors

-

Battery management systems (BMS)

-

EV power inverters and chargers

Automotive PCBs must deliver durability, precision, and high performance to support these technologies safely.

Key Considerations in Automotive PCB Design, Manufacturing & Testing

Automotive PCB development is governed by rigorous engineering requirements.

1. Automotive PCB Design

Thermal Management

Automotive PCBs must handle heat from the engine, power electronics, and LED modules. Techniques include:

-

High thermal-conductivity materials

-

Heat sinks

-

Thermal vias

-

Optimized copper thickness

Vibration Resistanc

To survive constant motion, designers must ensure:

-

Reinforced solder joints

-

Shock-resistant components

-

Optimized board layout for mechanical stability

2. Automotive PCB Manufacturing Process

Step |

Description |

|---|---|

| Material Selection | Choose FR-4, polyimide, aluminum, or other materials based on thermal and mechanical demands. |

| Circuit Pattern Formation | Use photolithography and etching to form conductive pathways. |

| Drilling & Plating | Via holes are drilled and copper-plated to establish interconnections. |

| Component Placement | High-precision assembly machines place SMD and through-hole components. |

| Soldering | Reflow or wave soldering ensures durable electrical and mechanical joints. |

| Conformal Coating | Protects against moisture, dust, and chemical exposure. |

| Final Inspection | AOI, X-ray, and functional tests evaluate manufacturing quality. |

3. Quality Control & Testing

Automotive PCBs undergo some of the most stringent tests in the electronics industry.

-

Thermal Cycling

Simulates extreme temperature swings to ensure solder joint durability. -

Vibration Testing

Replicates road and engine vibrations to detect mechanical weaknesses. -

Moisture & Corrosion Testing

Ensures reliability under humidity, condensation, and chemical exposure. -

Electrical Testing

Validates signal integrity, insulation resistance, and continuity. -

Standards Compliance

Most commonly: -

IATF 16949 (Automotive Quality Management)

-

ISO 9001

-

IPC-A-600 Class 3

These standards guarantee that automotive PCBs meet strict durability and performance expectations.

Conclusion

Automotive PCBs are essential to the performance, safety, and intelligence of today’s vehicles. From basic engine control to advanced ADAS systems, PCB quality directly influences a vehicle’s reliability and user experience.

Through robust design, precise manufacturing, and rigorous testing, automotive PCBs ensure durable, efficient, and safe electronic functioning in all operating conditions. As automotive technology continues to advance, PCBs will play an increasingly critical role in shaping future mobility.