ATE PCB Assembly is a critical process in the manufacturing of automated test equipment used for semiconductor and electronic device testing. Unlike standard PCB assembly, ATE PCB assembly must meet extremely high requirements for reliability, precision, and repeatability to ensure accurate test results and long-term system stability.

As ATE systems continue to support higher pin counts, faster signal speeds, and more complex test environments, professional ATE PCB assembly services have become essential for successful test system deployment.

What Is ATE PCB Assembly?

ATE PCB Assembly refers to the assembly of printed circuit boards specifically designed for automated test equipment. These PCBs serve as load boards, test interface boards, probe card interfaces, and other critical modules within ATE systems.

ATE PCB assembly integrates high-density components, precision connectors, sockets, and test interfaces while maintaining strict electrical and mechanical tolerances required for high-cycle testing applications.

Key Requirements for ATE PCB Assembly

High Reliability and Long Service Life

ATE PCBs operate in continuous test environments and must withstand repeated mechanical stress, thermal cycling, and long operational hours.

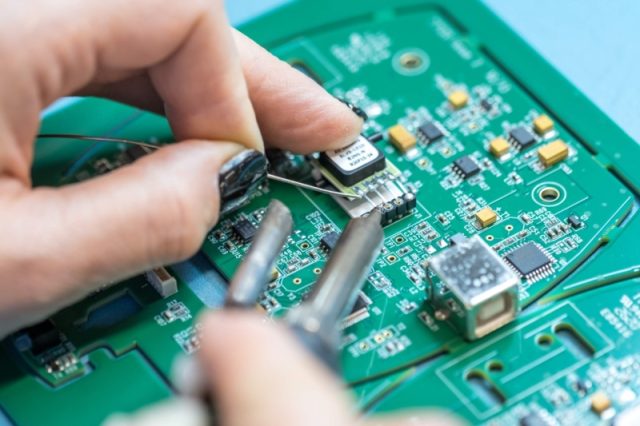

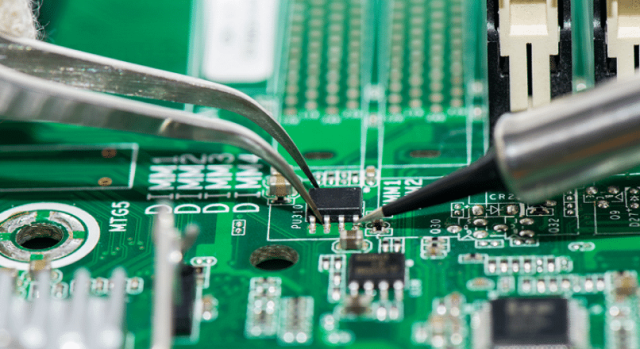

Precision Component Placement

High pin count devices, fine-pitch BGAs, and dense connectors require accurate placement and soldering to ensure electrical integrity.

Signal Integrity and Controlled Impedance

High-speed and RF test signals demand careful assembly processes that preserve controlled impedance and minimize signal degradation.

Mechanical Stability

ATE PCB assemblies must support frequent connector mating, DUT insertion, and probe contact without mechanical failure.

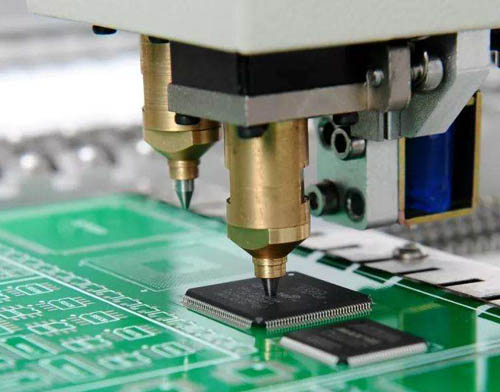

Assembly Capabilities for ATE PCB Assembly

Professional ATE PCB assembly services include advanced capabilities such as:

-

SMT and through-hole mixed assembly

-

Fine-pitch and high pin count component assembly

-

BGA, LGA, and QFN assembly and inspection

-

Controlled solder profile and thermal management

-

Precision connector and socket installation

-

AOI, X-ray inspection, and functional testing

These processes ensure consistent assembly quality for demanding ATE applications.

Materials and Components in ATE PCB Assembly

ATE PCB assembly often involves specialized materials and components:

-

Multilayer and high layer count PCBs

-

Controlled impedance and high-speed PCB designs

-

High-reliability connectors and test sockets

-

Low-loss materials for RF and high-frequency testing

-

Thick copper and reinforced structures for durability

Component selection and handling directly impact long-term test performance.

Engineering Support and Quality Control

Successful ATE PCB assembly requires close collaboration between design, manufacturing, and test teams:

-

DFM and DFA review before assembly

-

Assembly process optimization for test reliability

-

Inspection and traceability control

-

Electrical testing and functional verification

-

Documentation and quality reporting

Experienced ATE PCB assembly providers help reduce assembly-related failures and improve overall test system uptime.

Applications of ATE PCB Assembly

ATE PCB assembly is widely used in:

-

Semiconductor wafer testing systems

-

IC package and final test platforms

-

Logic and functional test equipment

-

Burn-in and reliability test systems

-

Automotive and industrial electronics testing

In these applications, assembly quality directly affects test accuracy, yield, and throughput.

From Prototype to Volume Assembly

ATE PCB assembly projects often begin with prototype or small-batch assembly to validate component placement, solder quality, and mechanical performance. Once confirmed, the same processes are scaled to volume assembly with strict process control to ensure consistency across all test systems.

Working with a single supplier for both PCB fabrication and ATE PCB assembly improves quality control and simplifies supply chain management.

Conclusion

ATE PCB Assembly is a mission-critical step in delivering reliable and accurate automated test equipment. Through precision assembly processes, high-quality components, and strict quality control, professional ATE PCB assembly providers ensure stable performance and long service life for semiconductor and electronic test systems.

As ATE systems continue to evolve, choosing an experienced ATE PCB assembly partner is essential for achieving repeatable test results and scalable production.