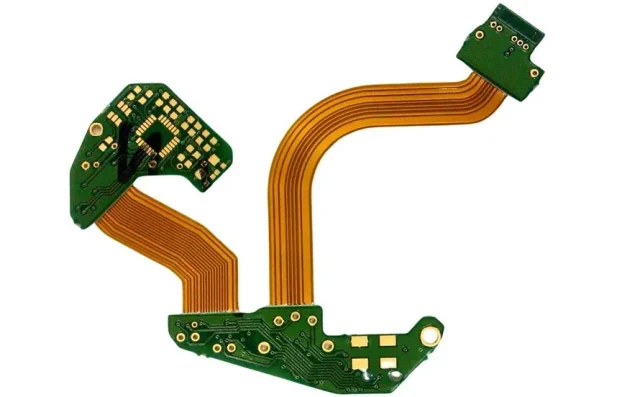

A Rigid-Flex PCB has become a foundational architecture for next-generation electronics that demand compact form factors, high-density interconnect, long-term mechanical durability, and stable signal integrity. By integrating rigid PCB layers with flexible polyimide circuits into a single laminated structure, a Rigid-Flex PCB eliminates traditional connectors, reduces wiring complexity, and enables true 3D electronic packaging. The result is a mechanically robust, lightweight, and electrically efficient platform engineered for demanding aerospace, medical, industrial automation, and portable consumer systems.

1. Rigid-Flex PCB as a High-Density Interconnect Backbone

Modern electronics continue to shrink, yet the performance expectations rise—higher speeds, tighter EMI control, and greater thermal reliability. A Rigid-Flex PCB directly addresses these conflicting demands by merging rigid FR-4 or high-speed laminate cores with flexible polyimide dielectric layers.

Key structural advantages include:

• Connector-free interconnect → dramatically lower failure rates

• Compact 3D folding for ultra-dense electronic packaging

• Reduced parasitics and shorter signal paths → higher signal integrity

• Stable impedance in flex regions for RF and high-speed applications

• Weight reduction critical for aerospace and wearables

The hybrid architecture turns the Rigid-Flex PCB into a multi-functional interconnect backbone rather than just a circuit carrier.

2. Material Engineering: The Foundation of Rigid-Flex PCB Reliability

The performance of a Rigid-Flex PCB depends heavily on the synergy between its rigid and flexible sections.

Rigid PCB materials:

• High-Tg FR-4 for thermal robustness

• Low-loss RF laminates for controlled impedance

• Halogen-free options for environmental compliance

Flex PCB materials:

• Polyimide dielectric with high thermal stability

• Adhesiveless PI for reduced thickness and improved bend reliability

• Rolled-annealed (RA) copper for dynamic flex endurance

• Polyimide coverlay with superior mechanical protection

High-frequency devices benefit from extremely stable dielectric properties, while dynamic systems rely on copper ductility and neutral-axis design—each controlled through precise Rigid-Flex PCB material selection.

3. Mechanical Engineering: The Core Strength of Rigid-Flex PCB

A well-designed Rigid-Flex PCB is mechanically optimized to withstand repeated bending cycles, vibration, shock, and thermal expansion mismatches.

Mechanical reliability enhancements include:

• RA copper with elongated grain structure for maximum bend life

• Accurate neutral-axis alignment to minimize tensile strain

• Staggered flex-to-rigid vias to distribute mechanical stress

• Teardrop pads, fillets, and relief slots in transition zones

• Calculated bend radius (≥10× flex thickness for dynamic flex)

Mechanical engineering is not optional—it defines whether a Rigid-Flex PCB survives thousands of cycles or fails prematurely.

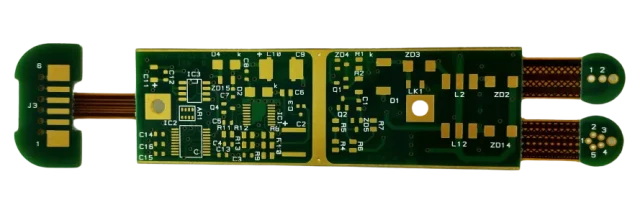

4. High-Density Routing and RF Performance in Rigid-Flex PCB

As systems increase in frequency and speed, the Rigid-Flex PCB becomes an enabler of high-performance electrical routing. HDI technology is commonly incorporated to maximize signal paths in a constrained footprint.

Electrical advantages include:

• Microvias and blind/buried vias for high-density layout

• Controlled-impedance flex traces for RF and mmWave routing

• Minimized interconnect length → lower insertion loss

• Improved EMI performance through optimized layer transitions

• Seamless high-speed differential pairs across rigid and flex regions

The Rigid-Flex PCB structure reduces discontinuities caused by connectors, greatly improving high-speed and RF signal integrity.

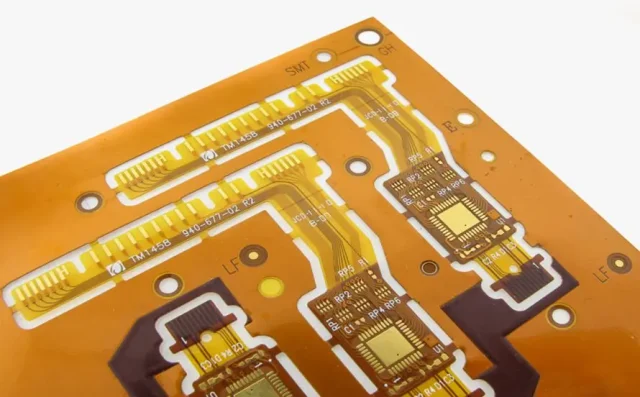

5. Precision Manufacturing for High-Reliability Rigid-Flex PCB

Fabricating a Rigid-Flex PCB requires strict process control and advanced manufacturing capabilities. Each lamination cycle must be executed with precision to avoid delamination, copper cracking, or registration drift.

Key manufacturing factors:

• Multistage lamination engineering

• Coverlay processing instead of solder mask for flex durability

• Controlled etching to maintain copper uniformity in flex regions

• Laser drilling for microvias and transition vias

• Tight dimensional tolerance across rigid-flex bonding areas

These processes ensure stable electrical performance and long mechanical lifespan.

6. Rigid-Flex PCB in High-Reliability Application Fields

The versatility and durability of the Rigid-Flex PCB make it indispensable across industries with strict reliability requirements:

• Aerospace avionics, satellites, and spaceborne electronics

• Defense systems, tactical communication devices, and ruggedized modules

• Medical wearables and surgical diagnostic instruments

• Industrial automation controls and robotic actuators

• Automotive ADAS sensors, radar, and camera modules

• High-speed consumer electronics and foldable devices

Where lightweight structure, compact routing, and long-term durability matter, a Rigid-Flex PCB performs far beyond conventional rigid boards.

Conclusion

The Rigid-Flex PCB is more than a hybrid structure—it is a high-density, high-reliability engineering solution for modern electronic systems facing mechanical, thermal, and signal-integrity challenges. Through advanced material control, precision mechanical design, and sophisticated HDI electrical engineering, a Rigid-Flex PCB provides unmatched performance in environments where failure is unacceptable. As next-generation devices continue to demand higher integration and more compact mechanical architecture, Rigid-Flex PCB technology remains at the center of innovation.