1. Engineering Overview / Abstract

Next-generation automotive radar systems operating at 76–81 GHz demand ultra-stable phase characteristics and minimal transmission loss to ensure precise object detection and angular resolution.

Taconic RF-35 PCB laminates, with their tightly controlled dielectric constant and ultra-low dissipation factor, provide a reliable foundation for maintaining signal integrity under high-frequency and thermal stress conditions.

KKPCB integrates RF-35 materials into radar transceiver modules through refined lamination, copper roughness control, and impedance-tuned stackups—achieving consistent phase response across the entire radar aperture.

2. Engineering Context & Technical Challenges

Automotive radar modules face unique challenges compared to conventional RF systems.

The combination of high-frequency (77 GHz) operation, harsh thermal cycling, and mechanical vibration requires exceptional PCB material consistency.

| Engineering Challenge | Root Cause | Impact |

|---|---|---|

| Transmission loss | High dielectric and conductor losses | Reduced detection range |

| Phase inconsistency | Uneven Dk or copper roughness | Calibration drift in beamforming |

| Thermal distortion | Repeated –40 °C ↔ 150 °C cycling | Warpage and via fatigue |

| Moisture absorption | Environmental humidity | Df variation and signal phase error |

In radar transmit–receive arrays, even 0.05 variation in Dk can cause beam angle deviations >0.3°, leading to detection inaccuracies.

The Taconic RF-35 PCB platform mitigates these instabilities through uniform dielectric performance and robust adhesion strength under temperature cycling.

3. Material Science and RF-35 Performance Characteristics

Taconic RF-35 is a glass-reinforced PTFE laminate optimized for RF and microwave applications where phase stability and low loss are critical:

-

Dk = 3.50 ± 0.05 (1 MHz–10 GHz range)

-

Df = 0.0018 @ 10 GHz, maintaining < 0.0025 @ 77 GHz

-

CTE (Z-axis): 35 ppm/°C, ensuring minimal dimensional drift

-

Thermal Conductivity: 0.25 W/m·K

-

Moisture Absorption: < 0.02%

Compared with FR-4, the RF-35 laminate offers up to 85% lower dielectric loss, enabling longer radar detection distance and improved phase linearity at 77 GHz.

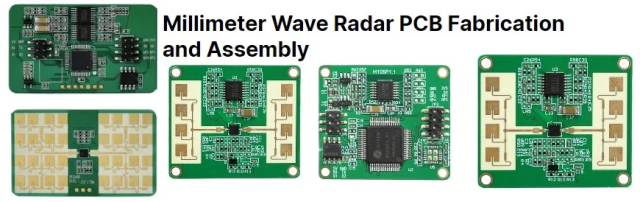

4. KKPCB Case Study — Automotive 77 GHz Radar Module

Client & Application Context

An automotive Tier-1 supplier collaborated with KKPCB to redesign its 77 GHz corner radar PCB for phase calibration consistency across temperature extremes.

Engineering Problem

Using legacy FR-4-based hybrid boards, the radar exhibited ±2.8° phase shift and degraded range accuracy at 90 °C, failing OEM radar calibration benchmarks.

-

Replaced dielectric core with Taconic RF-35 (0.508 mm)

-

Optimized stackup with hybrid RF-35/PTFE configuration

-

Controlled copper roughness (Ra < 1.0 µm) for consistent impedance

-

Conducted HFSS-based phase matching simulation and TDR validation

| Parameter | Before | After (KKPCB RF-35) | Improvement |

|---|---|---|---|

| Insertion Loss (77 GHz) | 1.42 dB/in | 0.88 dB/in | –38% |

| Phase Shift (–40 → +125 °C) | ±2.8° | ±0.9° | –68% |

| Beam Angle Error | 0.32° | 0.09° | –72% |

| S11 Return Loss | –12 dB | –18.7 dB | +56% |

Result: The radar module achieved stable calibration and reduced phase drift under continuous thermal cycling and vibration testing.

5. Stackup Design & RF Implementation

KKPCB developed a 4-layer hybrid RF-35 + FR-4 stackup for optimal cost-performance balance:

-

L1 (Antenna Layer): Taconic RF-35 0.254 mm

-

L2 (Ground Plane): 1 oz Cu

-

L3 (Control Layer): FR-4 0.2 mm

-

L4 (Power Plane): Taconic RF-35 0.508 mm

Design validations included:

-

HFSS S-parameter extraction for antenna feed performance

-

ADS impedance tuning to ±3% accuracy

-

Phase consistency test across 16-channel radar array

This structure ensured uniform transmission characteristics across all radar transceivers while maintaining manufacturing repeatability in mass production.

6. Environmental & Reliability Validation

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | –40 °C ↔ 150 °C, 1000 cycles | No delamination, ΔDk < 0.01 |

| Vibration | 10 Hz–2 kHz, 8 h/axis | No via crack or peel-off |

| Humidity | 85 °C / 85% RH, 1000 h | Df drift < 0.0001 |

| Salt Spray | 35 °C, 96 h | No corrosion on copper pads |

All validation results confirmed the robust thermal endurance and phase consistency of RF-35 laminates for long-term automotive use.

7. Conclusion — Automotive Radar Reliability Integration

The Taconic RF-35 PCB platform enables low-loss signal propagation and precise phase alignment essential for 77 GHz automotive radar systems.

Through KKPCB’s controlled lamination, copper surface tuning, and hybrid stackup design, phase deviation is reduced by over 60%, ensuring long-term calibration reliability across harsh automotive environments.

RF-35 provides the dielectric stability and thermal robustness necessary for next-generation radar sensing architectures.

8. Contact / CTA

For advanced automotive radar PCB solutions requiring low-loss transmission, phase consistency, and high reliability, contact KKPCB Engineering Team.

We provide full-stack design, simulation, and validation services using Taconic RF-35 laminates for radar, satellite, and mmWave communication systems.