1. Engineering Overview / Abstract

As 5G smartphone antenna modules integrate multiple MIMO paths and beam-forming arrays, precise impedance control and thermal uniformity become critical for stable signal transmission.

Taconic RF-35 PCB substrates enable consistent dielectric performance and low-loss propagation under compact, multilayer conditions.

KKPCB engineers apply fine-tuned lamination and impedance verification processes to maintain phase coherence and low insertion loss across high-density 5G antenna feed networks.

2. Engineering Context & Technical Challenges

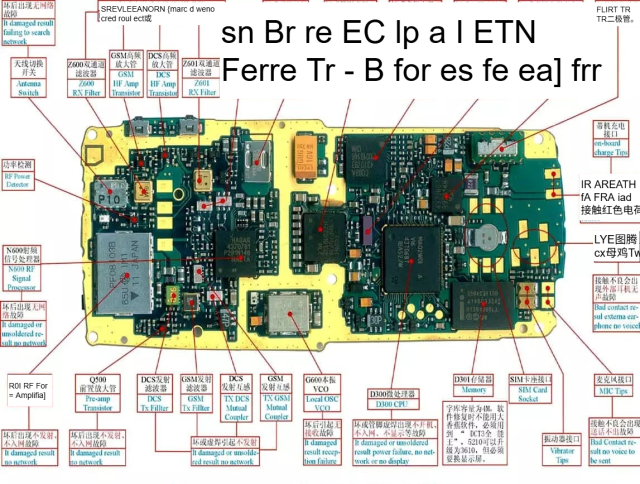

5G smartphone antenna modules combine RF front-end filters, power amplifiers, and antenna arrays within a tight thermal enclosure.

At frequencies up to 39 GHz, minor variations in dielectric or copper roughness can cause impedance mismatch and heat-induced detuning.

| Engineering Challenge | Root Cause | Impact |

|---|---|---|

| Impedance drift | Dielectric non-uniformity | Return loss and phase imbalance |

| Thermal distortion | Localized power density | Frequency shift in antenna array |

| Signal loss | High conductor roughness | Degraded link efficiency |

| Material expansion | CTE mismatch in hybrid stackups | Micro-warpage and solder fatigue |

In such miniaturized modules, Taconic RF-35 PCB offers tight Dk tolerance and low thermal expansion, mitigating both impedance and phase drift across thermal cycles.

3. Material Science and Performance Characteristics

Taconic RF-35 Laminate Properties

-

Dk = 3.50 ± 0.05 @ 10 GHz

-

Df = 0.0018 @ 10 GHz

-

CTE (Z-axis) ≈ 35 ppm/°C

-

Thermal Conductivity ≈ 0.25 W/m·K

-

Moisture Absorption < 0.02 %

Compared to standard FR-4, RF-35 offers > 80 % lower loss tangent and ~60 % better phase linearity at mmWave frequencies.

These advantages enable stable antenna matching and low VSWR within compact smartphone modules.

4. KKPCB Case Study — 5G Smartphone Antenna Feed Module

Client & Application Context

A global smartphone OEM partnered with KKPCB to reduce impedance variance and thermal deformation in its 5G antenna module based on Taconic RF-35 substrates.

Engineering Problem

Early prototypes showed ±6 Ω impedance fluctuation and phase instability under 85 °C thermal load, causing antenna gain variation > 1.5 dB.

-

Optimized lamination at 195 °C with vacuum pressure control (< 2 % resin voids)

-

Adjusted Cu roughness (Ra < 1.0 µm) to reduce loss at 28 GHz

-

Applied inline TDR scanning for impedance uniformity ±3 %

-

Hybridized FR-4 control layers for mechanical balance

| Parameter | Before | After (KKPCB RF-35) | Improvement |

|---|---|---|---|

| Impedance Uniformity | ±6 Ω | ±2.1 Ω | 65 % |

| Phase Stability (28 GHz) | ±1.8° | ±0.7° | 61 % |

| Insertion Loss | 0.45 dB/in | 0.29 dB/in | 36 % |

| Thermal Drift (–40↔85 °C) | 0.11 mm | 0.04 mm | 64 % |

Result: Stable antenna calibration and consistent beam pattern across all production lots.

5. Stackup Design & RF Implementation

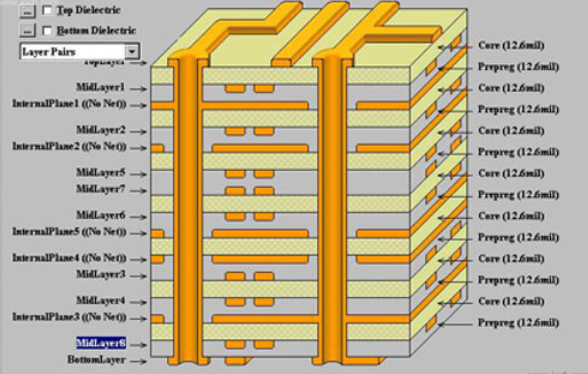

KKPCB designed a 4-layer hybrid stackup for 5G antenna modules to balance thermal and electrical performance:

-

L1: RF Feedline — Taconic RF-35 0.254 mm

-

L2: Ground — 1 oz Cu

-

L3: Control Layer — FR-4 0.18 mm

-

L4: Radiator — Taconic RF-35 0.508 mm

Design verification included HFSS simulation, ADS matching network tuning, and TDR validation at 39 GHz, achieving excellent impedance correlation between model and measurement (< ±0.05 dB variance).

6. Environmental & Reliability Validation

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | –40 ↔ 125 °C, 1000 cycles | No delamination, ΔDk < 0.01 |

| Humidity Test | 85 °C / 85 % RH, 1000 h | Df drift < 0.0001 |

| Mechanical Bending | 50 cycles at R5 mm | No crack or lift-off |

| Reflow Simulation | 260 °C peak 3 times | No warpage > 0.05 mm |

Results demonstrate that RF-35 PCBs maintain electrical and mechanical integrity under typical smartphone assembly and usage conditions.

7. Conclusion — Engineering Reliability Integration

The Taconic RF-35 PCB platform provides stable impedance, low loss, and excellent thermal uniformity for 5G smartphone antenna modules.

Through KKPCB’s precision lamination control, copper surface optimization, and real-time impedance verification, designers achieve phase-consistent RF performance even under thermal stress.

This integration ensures mass-production reliability for next-generation 5G devices.

8. Contact / CTA

For customized Taconic RF-35 PCB designs supporting 5G antenna, mmWave, and RF front-end modules, contact KKPCB Engineering Team.

We provide simulation-driven stackup design, impedance validation, and thermal stability analysis for smartphone and wireless communication systems.