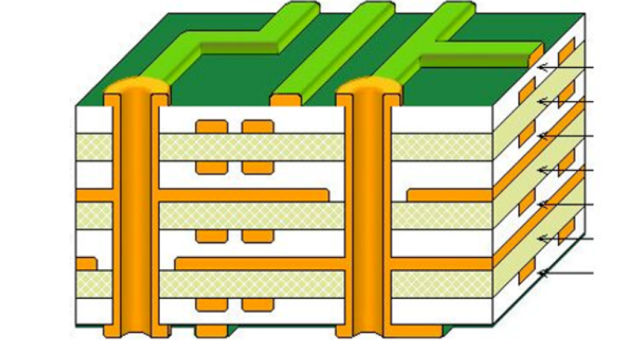

The three main characteristics of Rigid-Flex PCB are Multi-bending, Multi-stackup, and Multi-zone.

In the previous article, we discussed multi-bending designs. In this article, we will take a closer look at the multi-layered design of Rigid-Flex.

01、 Multi-Stackup

Multi-layer stack

Multi-stackup refers to a substrate where the number and thickness of layers differ in different regions, meaning the substrate needs to define multiple stacked structures.

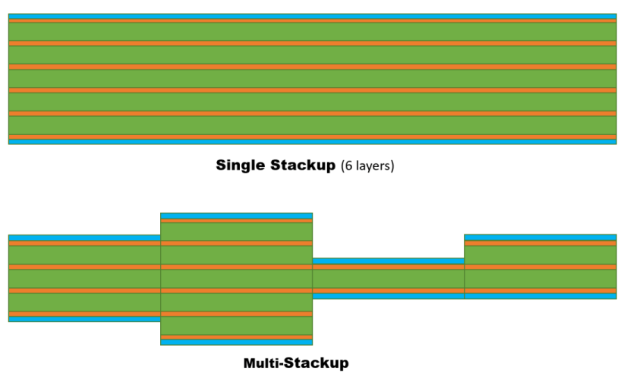

Single Stackup

Regardless of the substrate, there is at least one layer stack-up structure. For example, the common 4-layer, 6-layer, and 8-layer boards all correspond to a layer stack-up structure, which we call a single stack-up. The image below shows the stack-up structure of an 8-layer board.As you can see, although it’s a single stack-up structure, the number of layers can be quite large. Many PCB boards , although single-layered, may have dozens or even hundreds of layers. Because the entire board uses a single stack-up, it’s called a single stack-up structure. In reality, the layer stack-up requirements differ in different locations on the substrate. Some areas require a large number of layers to increase wiring density and routing efficiency, while others only need a small number of wirings. So, can different stack-ups be used in different areas of the board? The answer is yes; this is the idea behind multi-layer stack-ups. The image below compares single-layer and multi-layer stack-up structures:

So, how do we design multi-layered structures?

Multi-Stackup

For rigid-flexible circuit boards, due to significant functional differences in different areas, some areas require bending or folding, while others need reinforcement to mount components . A single layer stack is insufficient, necessitating the use of multi-stackup structures. The thickness and stacking structure vary at different locations on the board, as shown in the figure below. Thicker layers are typically used in rigid sections, while thinner layers are used in flexible circuit sections to facilitate bending and folding.

Multi-Stackup

There may be dozens of different stack definitions for a multi-stackup structure. As long as the stack thickness or the materials in the stack are different, a new stack needs to be defined.

In the image below, we can see that there are already 9 cascading definitions: Primary, Flex, Flex2, A, B, C, D, E, and F. By clicking the “+” sign on the far right, we can continue to add new cascading definitions.

Of all these stacked structures, we can define new stacks or delete existing stacks, but there is one stack that cannot be deleted and is always in the default position. This stack is called the Primary Stackup.

Primary Stackups exist in both multi-level and single-level stackups. Single-level stackups only have Primary Stackups, while multi-level stackups consist of Primary Stackups plus other Stackups.

In the Stackup software design, multiple stacking structures are defined, and corresponding layers are specified for each stack, thus completing the multi-layer stack design.

02、 Layers in Stackup

Different types of layers

A stack consists of different layers, which can be divided into conductor layer, dielectric layer, and mask layer.

The basic characteristic of multilayer boards is that conductor layers and dielectric layers are placed alternately, then laminated together, and the circuits of each layer are connected through vias . The process of laminating the substrate first and then drilling holes is called lamination.

Because lamination uses mechanical drilling, the hole diameter and spacing are relatively large, making it difficult to meet the needs of high-density designs. As design density increases, laser drilling is used. Laser drilling is efficient, with small hole diameter and high density. However, lasers can usually only burn through the medium and will be reflected when they encounter metal. Therefore, only one hole can be drilled, one layer can be laminated, and then another hole can be drilled and laminated again, accumulating layer by layer. Hence, it is called the buildup method.

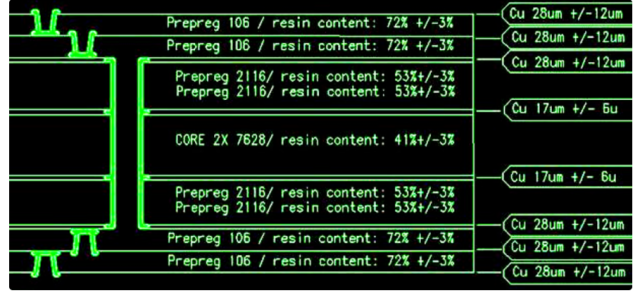

The lamination method uses a high glass fiber content as the dielectric, resulting in higher strength and hardness. The stacking method uses a high resin content as the dielectric, resulting in a softer texture and higher laser drilling efficiency. In practical applications, lamination and stacking methods are often used in combination. For example, lamination is used in the middle layers to enhance the board’s strength, while stacking is used in the outer layers to improve laser drilling efficiency and drilling density.

The figure below shows an 8-layer substrate. The middle 4 layers are laminated, and the outer 4 layers are stacked, which is called a 2+4+2 stacked structure.

In addition to the top and bottom conductor layers of the substrate, a mask layer is usually applied. For a single-layer rigid substrate, these mask layers are typically solder mask layers.

For rigid-flex circuits, there are many types of mask layers, typically including: solder mask, coverlay, EMI shielding, selective plating, and stiffener. These mask layers can be divided into two main categories: conductor masks and non-conductor masks.

Soldermask

Solder mask is used in both rigid substrates and rigid-flex circuits. In flexible circuits, the solder mask layer is a cured epoxy-based liquid, meaning it is initially liquid. It is printed onto the substrate surface using a photomask, serving to isolate and protect the solder pads. Generally, it is presented as a negative in the design, meaning the areas with patterns are cut out, and the areas without patterns are filled with epoxy groups. In practical applications, solder masks are often green, hence the name “green solder mask.” However, the color can be flexibly chosen, so other colors of solder masks are also available.

A new type of solder mask, called LPI or LPISM (Liquid Photo Imager Solder Mask), is currently available . It is a two-component liquid ink that is mixed before application to maintain its shelf life. LPI is superior to epoxy-based liquids, allowing for precise printing, better contact with the PCB, and therefore greater durability.

Coverlay

Coverlays are commonly used in flexible circuits. They employ a polyimide overlay and function similarly to solder masks, providing insulation and protection for the outer circuitry. Coverlays are typically thin films, usually solid sheets of polyimide, unlike solder masks which solidify from a liquid state to a hardened state. In terms of design, coverlays often use a positive design, meaning that empty areas are cut out and graphic areas are covered. Coverlays are often orange-yellow and are used to cover areas in rigid-flex circuits that require insulation and protection.

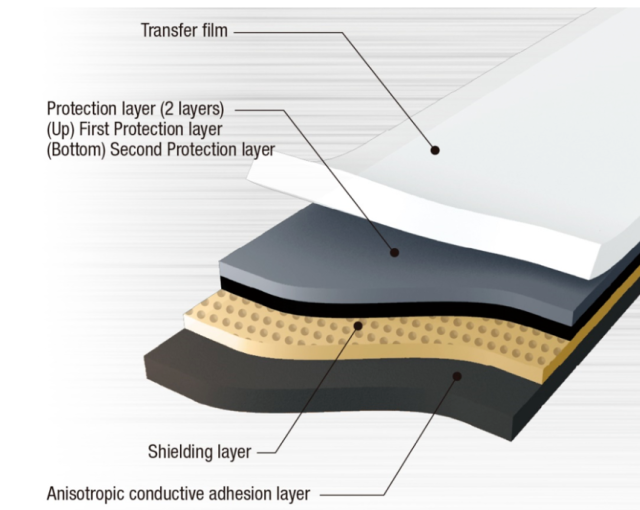

EMI Shielding

EMI shielding can shield or reduce the transmission of electromagnetic fields, eliminating unwanted electromagnetic interference . It prevents signals from entering sensitive systems or from escaping from noisy systems. EMI shielding can reduce many different types of interference, including electromagnetic fields, electrostatic signals, and radio waves (EMI).

In Rigid-Flex, EMI shielding is typically a large-area conductive film covering the substrate surface. Through openings in the solder mask or coverlay, small metal shapes are connected to the GND of the top conductor.

EMI shielding has a protective layer on top and an adhesive layer on the bottom for bonding to the substrate.

Selective Plating

Selective plating is a process where only a portion of the substrate’s surface is plated, rather than the entire surface. This process is often referred to as selective plating or brush plating. In some cases, selective plating can resemble soldering, such as plating the surface of solder pads. The operator holds a flexible brush and applies the plating solution to the pads, using the same principle as electroplating to metallize the pad surface.

Stiffener reinforcement layer

In certain areas of flexible PCB, the substrate needs to be reinforced due to the need to weld components. These reinforced parts are called stiffeners.

Stiffeners typically lack electrical properties; they provide localized structural reinforcement for flexible circuits and offer structural support for devices and connectors .

The above layer types are the layers commonly used in Rigid-Flex.