A Deep Dive into ADAS PCB Assembly — KKPCB’s Approach to Automotive Precision

Advanced Driver Assistance Systems (ADAS) stand at the forefront of automotive innovation, reshaping how vehicles perceive and respond to their surroundings. From adaptive cruise control to automatic emergency braking, these intelligent systems rely on high-performance printed circuit boards (PCBs) to process massive streams of data with split-second accuracy. At KKPCB, we bring deep expertise and precision engineering to ADAS PCB assembly — ensuring every board delivers reliability, safety, and efficiency in the most demanding automotive environments.

What Defines ADAS PCB Assembly

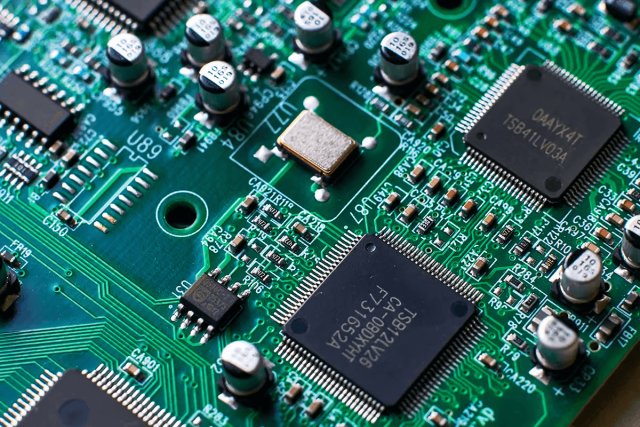

ADAS PCB assembly is a specialized manufacturing process that integrates precision, heat resistance, and electrical integrity into every circuit layer. These boards must endure extreme conditions — from -40°C to 85°C, under constant vibration and exposure to moisture — while maintaining flawless signal transmission for radar, LiDAR, and camera systems.

KKPCB’s automotive-grade PCB assembly ensures that every connection meets strict impedance control requirements (often ±10% tolerance) and adheres to global automotive standards such as AEC-Q100 and ISO 26262. Our production lines are built for consistency, with component placement precision down to 0.01 mm and automated traceability across every batch.

Key Processes Behind KKPCB’s ADAS PCB Assembly

1. Surface Mount Technology (SMT) for Automotive Applications

KKPCB employs high-speed SMT lines capable of placing over 100,000 components per hour with sub-millimeter accuracy. Using lead-free solder paste and advanced stencil printing, components like microcontrollers, sensors, and ICs are mounted seamlessly onto densely packed ADAS boards.

Automotive SMT assembly demands stability across thermal cycles, so KKPCB ensures optimal solder integrity using SAC305 alloys and real-time process monitoring. The result — reliable interconnects that withstand temperature swings and vibration stress.

2. Reflow Soldering Techniques for Thermal Reliability

Once components are placed, reflow soldering locks them in with precision. KKPCB’s multi-zone reflow ovens follow optimized thermal profiles — gradually heating to 240–260°C before controlled cooling — ensuring perfect wetting and joint formation without voids or tombstoning.

For radar and high-speed data circuits, thermal balance is critical. Our engineers continuously calibrate temperature gradients and solder paste viscosity to maintain consistent electrical performance and mechanical integrity.

3. Wave Soldering for Through-Hole Components

While most ADAS assemblies rely on SMT, certain modules — like power connectors and high-current circuits — require through-hole components. KKPCB integrates selective wave soldering systems that apply molten solder precisely where needed, minimizing thermal stress on sensitive nearby components.

We utilize high-purity tin-silver-copper (SAC) alloys to ensure mechanical durability and fatigue resistance under prolonged vibration, meeting the lifetime requirements of automotive applications.

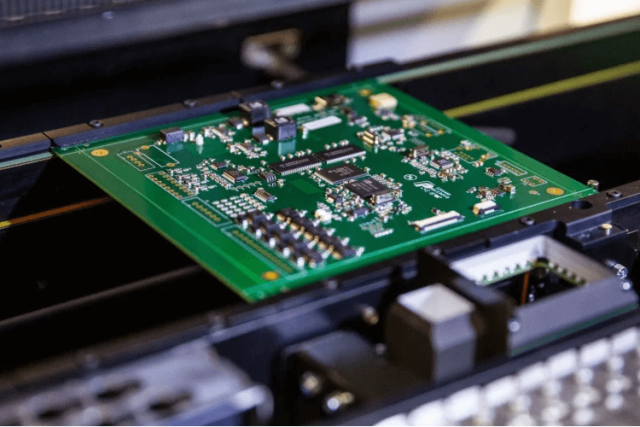

4. Automated Optical Inspection (AOI): The Final Guardian of Quality

Every ADAS board undergoes rigorous 3D Automated Optical Inspection (AOI) to detect solder defects, misalignment, and micro-level inconsistencies. Our AOI systems compare each board against a digital “golden image,” analyzing height, shape, and joint volume with sub-50µm precision.

For safety-critical ADAS functions, this level of inspection is non-negotiable. One faulty solder joint in a radar module can compromise vehicle safety — which is why KKPCB enforces near-zero defect standards through fully integrated optical and electrical testing.

Overcoming Challenges in ADAS PCB Assembly

Building ADAS boards means navigating complex constraints — from high-density layouts prone to signal crosstalk to thermal management issues caused by densely packed chips. KKPCB engineers employ controlled impedance layer stack-ups, thermal vias, and selective potting to ensure robust heat dissipation and electromagnetic compatibility (EMC).

We also implement conformal coatings to protect assemblies from corrosion and contaminants, ensuring long-term reliability under harsh automotive conditions. Each step aligns with functional safety requirements (ASIL) under ISO 26262.

Best Practices That Define KKPCB’s Quality

-

Design for Manufacturability (DFM): Optimized pad spacing, component orientation, and reflow profiles for zero-defect production.

-

High-Reliability Materials: Using Tg≥170°C laminates and lead-free solder alloys for thermal endurance.

-

Precision Process Control: Automated monitoring of placement accuracy, solder joint geometry, and thermal consistency.

-

Comprehensive Testing: ICT, AOI, and full functional simulation under real automotive conditions.

-

Full Traceability: Digital tracking of every component and process step for safety compliance and quality assurance.

Why Partner with KKPCB for ADAS PCB Assembly

ADAS PCB assembly isn’t just about placing components — it’s about ensuring mission-critical reliability in systems that make split-second safety decisions. KKPCB combines state-of-the-art automation, automotive-grade materials, and rigorous testing protocols to deliver assemblies that exceed industry standards.

With experience across radar, camera, and power control modules, KKPCB is more than a manufacturer — we’re your engineering partner in the evolution toward autonomous mobility.

Conclusion

As vehicles evolve from assistance to autonomy, the reliability of ADAS electronics defines the safety of every journey. KKPCB’s integrated approach to ADAS PCB assembly — combining precision SMT, optimized soldering processes, and rigorous inspection — ensures every board operates flawlessly in real-world conditions.

In the fast-changing landscape of automotive innovation, KKPCB stands at the intersection of precision engineering and functional safety, driving the future of intelligent mobility.