Ensuring High-Frequency Stability and Heat Dissipation Integrity Through KKPCB’s Advanced RF Lamination Framework

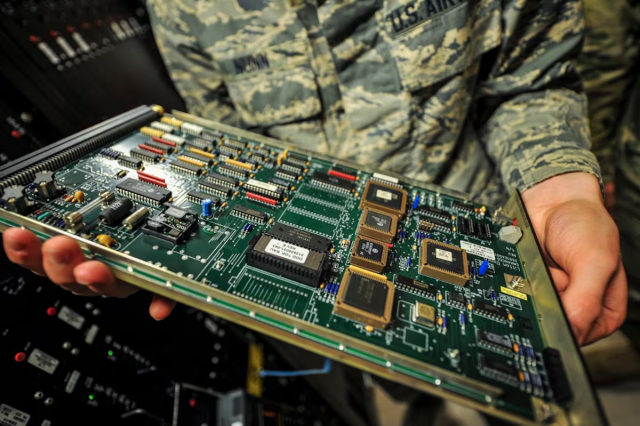

1. Introduction — The Hidden Heat Challenge in Aerospace RF Systems

As defense radar modules and satellite tracking systems migrate toward Ka- and W-band frequencies, the thermal load within power amplifier and antenna front-end PCBs grows dramatically.

At these mmWave power densities (often exceeding 3–5 W/cm²), even a small mismatch in dielectric constant or copper interface can induce localized heating, resulting in:

-

Phase drift under transient load,

-

Substrate deformation during long-term flight cycles, and

-

Deterioration of metallized via conductivity.

Rogers Duroid 5880, with its ultra-low dielectric loss (Df = 0.0009) and thermal conductivity of 0.22 W/m·K, offers a strong foundation for high-power RF design. Yet, ensuring its thermal and dimensional reliability under defense-level operating profiles requires specialized lamination, via, and copper management strategies—areas in which KKPCB’s aerospace RF engineering process plays a defining role.

2. Why Duroid 5880 Faces Power-Induced Reliability Risks

Even though Duroid 5880 is PTFE-glass composite with excellent dielectric uniformity, its low mechanical stiffness and limited heat transfer capacity make it vulnerable under repetitive high-power radar cycles.

| Failure Mode | Root Cause | Impact on Radar Performance |

|---|---|---|

| Thermal Drift | Non-uniform heat dissipation across multilayer arrays | Phase instability and target position error |

| Delamination at Bond Line | CTE mismatch between 5880 core and bonding film | Mechanical fatigue under –55°C~+150°C |

| Via Barrel Fatigue | Inconsistent plating during high thermal cycling | Power drop and return loss degradation |

| Dk Shift Under Heat | Resin relaxation during reflow or flight stress | Frequency offset and reduced detection range |

KKPCB’s process development team introduced a multi-stage lamination control and thermal compensation protocol specifically tailored for high-frequency radar transmit boards.

3. KKPCB’s Thermal Reliability Framework for Duroid 5880

3.1 Hybrid Lamination and CTE Matching Control

-

Duroid 5880 paired with RO4450F bonding film (CTE_z < 60 ppm/°C) to balance expansion in multilayer stackups.

-

Lamination profile: 175°C / 90 min / 200 psi / controlled cooling (1.5°C/min) to suppress stress gradients.

-

Achieved interlayer thickness tolerance: ±8 µm.

3.2 Heat Spreading and Copper Plane Optimization

-

RF microstrip layers over 2 oz RA copper with embedded thermal vias under power devices.

-

0.2 mm staggered via grid improves vertical conduction without altering impedance profile.

-

Simulation (ANSYS Icepak) confirms 22% lower junction temperature at 60 W load.

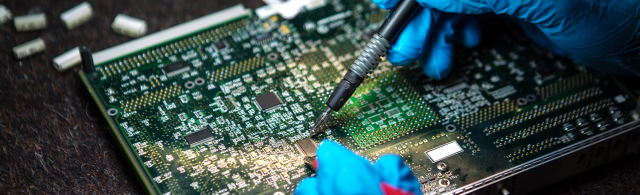

3.3 Via Reliability and Barrel Integrity Validation

-

Electroless copper seed layer + pulse plating for improved ductility.

-

After 1000 thermal cycles (–55°C ↔ +150°C), via resistance change < 3%.

-

X-ray microsectioning shows no barrel cracks or resin pull-out.

4. Case Study — X-Band Airborne Synthetic Aperture Radar (SAR) Transmit Module

Client: Military avionics integrator (confidential)

Application: 9.4 GHz X-band airborne SAR power module

Objective: Achieve stable output power and phase tracking within ±0.5° during continuous flight operations at high duty cycle (>70%).

Challenges Identified

-

Power transistors induced >105°C local hotspot at via clusters.

-

Slight dielectric creep during long-term exposure caused 0.3 dB insertion loss rise.

KKPCB Solution

-

Integrated copper heat spreader in-core within Duroid 5880 mid-layer stack.

-

Optimized via-in-pad array with thermal fill to maintain impedance.

-

Added vacuum lamination + slow cooling gradient to relieve resin stress.

-

Conducted 85°C/85% RH reliability test (1000 h) + 94 GHz RF revalidation.

| Parameter | Before Optimization | After KKPCB Process |

|---|---|---|

| Local Hotspot Temp | 105°C | 82°C |

| Insertion Loss | 0.35 dB/inch | 0.26 dB/inch |

| Phase Drift | 1.7° | 0.6° |

| Reliability (1000h) | Micro-delam at vias | No failures observed |

Outcome:

The improved module achieved < 1°C/min thermal equilibrium rate and retained >99.2% RF phase coherence under extended airborne vibration and temperature cycling.

5. Design and Validation Recommendations

-

Maintain thermal gradient symmetry within ±3°C per layer to avoid Dk shift.

-

Employ embedded copper slugs or filled thermal vias near PA regions.

-

Avoid reflow cycles >2 to preserve PTFE microstructure integrity.

-

Perform RF thermal scanning (using IR + VNA) post-lamination for power mapping.

-

Validate mechanical endurance using MIL-STD-202 Method 107G.

6. KKPCB’s Thermal Assurance Program

| Test Item | Method | Evaluation Target |

|---|---|---|

| Thermal Cycling | –55°C~+150°C / 1000 cycles | Via integrity, Dk drift |

| Power Endurance | 10W/cm² @ 10GHz for 48h | Copper adhesion, phase stability |

| Moisture & Reflow | 85°C / 85% RH / 1000h | Delamination resistance |

| Thermal Shock | 5s immersion @ ±125°C | Bond line reliability |

KKPCB integrates real-time RF impedance and phase mapping after each reliability test, ensuring Duroid 5880-based radar modules sustain mission-grade performance.

7. Conclusion — Turning Material Stability into Field-Proven Reliability

Duroid 5880’s low-loss chemistry makes it an ideal base for mmWave radar, but its thermal softness and CTE imbalance can be critical risk factors in high-power aerospace modules.

Through KKPCB’s hybrid lamination, precision copper balancing, and full-cycle reliability verification, the board not only survives thermal stress but also maintains electrical consistency under mission-level endurance.

KKPCB converts Duroid 5880’s dielectric precision into defense-grade RF stability, enabling reliable radar imaging, guidance, and electronic warfare systems across the most demanding aerospace environments.