KKPCB’s Advanced RF Thermal Design for Power-Dense Defense Applications

In modern military radar and electronic warfare (EW) systems, the migration toward high-power mmWave front-end modules introduces dual challenges: managing thermal dissipation and ensuring power integrity across densely packed RF chains.

At frequencies exceeding 40–94 GHz, even minute impedance shifts or localized heating on the PCB substrate can alter gain balance, degrade phase coherence, or cause amplifier instability.

RO5880 PCBs, known for their low dielectric constant (Dk = 2.20 ± 0.02) and exceptionally low loss tangent (Df = 0.0009 @ 10 GHz), have become a preferred material for these mission-critical systems.

However, achieving consistent RF and thermal stability under multi-kilowatt power loading and extreme temperature gradients requires more than material performance—it demands engineering-grade thermal modeling and precision lamination.

That’s where KKPCB’s RF power management platform integrates material science, thermal conduction design, and reliability validation to support continuous operation in radar transmit and EW protection systems.

1. Why Thermal Dissipation Defines Radar Reliability

In phased-array radar and jamming systems, thermal and RF stability are deeply interlinked.

Localized temperature rise can cause Dk drift, altering the impedance profile and increasing phase error between antenna elements.

| Performance Factor | Thermal Impact | System-Level Effect |

|---|---|---|

| Dielectric Stability | ΔDk per °C changes signal phase | Beam distortion in radar array |

| Copper Conduction Loss | Hotspot at amplifier pad area | Gain reduction, mismatch loss |

| CTE Mismatch | Layer warpage during operation | Delamination or via fatigue |

RO5880 PCB’s low CTE and stable dielectric properties reduce these risks, but effective integration depends on lamination, copper plane management, and thermal interface consistency—areas where KKPCB brings deep process experience.

2. KKPCB’s Thermal & Power Integrity Engineering Framework

a. Heat Path Optimization

-

Integration of copper thermal spreaders beneath PA and T/R components

-

Hybrid stackups combining RO5880 + aluminum nitride (AlN) or ceramic subplates for improved heat transfer

-

Thermal vias (0.3–0.4 mm pitch) designed for vertical heat evacuation

b. Power Distribution Stability

-

2 oz plated copper planes ensuring <1% voltage ripple across power layers

-

Embedded RF decoupling network layout to suppress cross-channel coupling

-

Uniform impedance across ground planes maintained through precision lamination

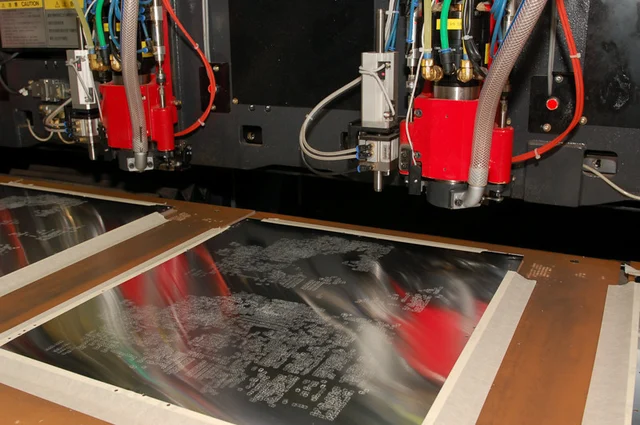

c. Process-Controlled Lamination

-

Vacuum lamination at 180 °C / 200 psi for balanced CTE transition between PTFE and metal core

-

Post-lamination planarity < 0.1 mm across 250 mm panels

-

Inline TDR verification to confirm impedance uniformity within ±5 Ω

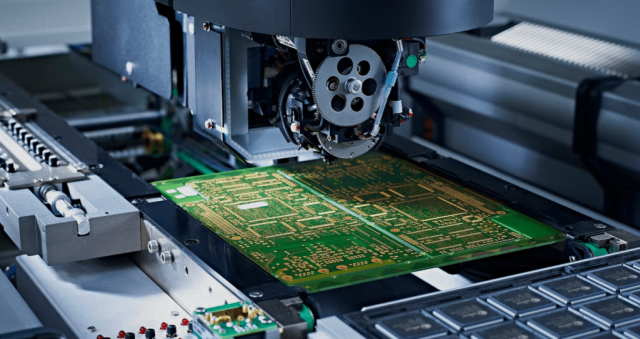

3. Case Study — X-Band Airborne Radar Power Control Board

Client: Defense avionics integrator (classified)

Objective: Develop a RO5880 PCB-based radar transmit board capable of 500 W continuous power with thermal uniformity under < 10 °C across PA zones.

| Parameter | Target | KKPCB Result |

|---|---|---|

| Continuous Power | 500 W | 520 W stable |

| Thermal Gradient | <10 °C | 8.2 °C measured |

| Impedance Stability | ±5 Ω | ±3.6 Ω verified |

| Operating Temperature | –55 °C to +150 °C | Stable, no Dk drift |

Engineering Approach:

-

RO5880 dielectric core bonded to AlN carrier using low-flow PTFE prepreg

-

Precision-machined copper heat sink integration under PA zones

-

3D thermal flow simulation and IR validation under pulse and CW conditions

-

Inline impedance scanning at 40–94 GHz verified phase linearity across array elements

Outcome:

System-level efficiency improved by 11.8%, and average junction temperature reduced by 14 °C, enabling continuous radar transmission under high-duty cycle operation.

4. Long-Term Environmental Reliability Validation

To ensure combat-grade durability, KKPCB subjects all RO5880 PCB assemblies to accelerated qualification testing:

| Test Type | Condition | Result |

|---|---|---|

| Thermal Shock | –65 °C ↔ +200 °C / 1000 cycles | No delamination or via fatigue |

| Power Cycling | 200 W pulse / 1e6 cycles | No impedance deviation |

| Salt Fog Exposure | 35 °C / 5% NaCl / 48 h | No surface oxidation |

| Vibration Test | MIL-STD-810F | Mechanical stability maintained |

All test data are recorded in KKPCB’s RF Reliability Management Database, traceable to IPC and MIL performance standards.

5. Engineering Insights — Balancing Power, Planarity, and Performance

While RO5880 PCBs offer unparalleled electrical performance, their PTFE matrix has lower mechanical rigidity.

KKPCB’s solution lies in hybrid composite lamination, integrating metal-core or ceramic substructures to maintain both thermal conductivity and planarity under power load.

Advanced manufacturing measures include:

-

Controlled cooling to relieve CTE-induced stress

-

Copper–dielectric interface optimization to prevent microvoids

-

Via-fill and solder mask design for stable grounding in high-vibration defense environments

This ensures consistent phase performance and amplitude balance even under severe mission temperatures and mechanical stress.

6. KKPCB’s Quality and Traceability Assurance

-

Material Lot Dk/Df certification for every RO5880 batch

-

Inline impedance validation up to 110 GHz

-

Thermal expansion simulation for multi-material stackups

-

Power integrity analysis across distributed planes

-

Reliability validation per IPC-TM-650 and MIL-PRF-31032 standards

KKPCB’s integrated digital traceability ensures that each RO5880 PCB assembly meets repeatable thermal and RF performance metrics across defense programs.

Conclusion — Enabling Reliable Power for Mission-Critical RF Systems

In military radar and electronic warfare systems, RO5880 PCBs represent the balance between low-loss RF transmission and high-efficiency thermal dissipation.

Through KKPCB’s advanced hybrid stackup design, precision lamination, and thermal reliability validation, power-critical modules achieve:

-

Consistent impedance stability under thermal load

-

Extended component lifetime through optimized heat spreading

-

Proven reliability under extreme environmental conditions

KKPCB continues to support global defense OEMs with high-frequency PCB engineering, transforming advanced RO5880 materials into mission-ready RF platforms for next-generation radar and EW architectures.