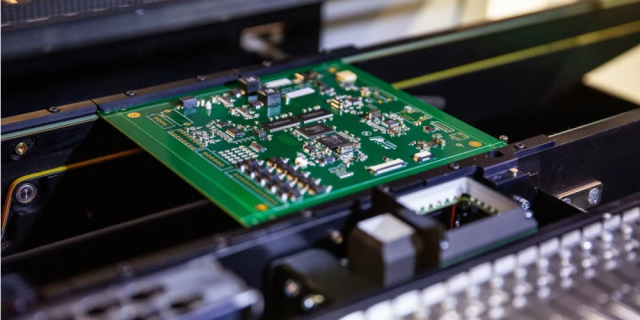

Ensuring Phase-Consistent Measurement Accuracy Through KKPCB’s Ultra-Low-Loss RF Manufacturing Platform

As mmWave calibration and test systems advance into the 40–110 GHz domain, every transmission line, connector, and RO5880 PCB trace within the measurement chain directly influences phase linearity and amplitude accuracy.

Even a minor 0.1 dB loss variation or 1° phase shift can distort calibration reference data—compromising measurement reliability across VNA and OTA systems.

The Rogers RO5880 substrate has become the material benchmark for such high-precision environments due to its ultra-low dielectric loss (Df = 0.0009 @ 10 GHz) and stable Dk = 2.20 ± 0.02.

However, translating these properties into long-term RF measurement consistency demands more than advanced materials—it requires metrology-grade process control and traceable PCB reliability validation.

This is where KKPCB’s engineered RF platform integrates material precision with manufacturing consistency to ensure reliable performance across all mmWave calibration applications.

1. Why Calibration Consistency Defines System Accuracy

In high-frequency environments such as 5G OTA chambers, satellite transceiver calibration benches, and automotive radar test systems, the interconnect RO5880 PCB must maintain:

-

Phase stability: < 1°

-

Amplitude deviation: < 0.1 dB

-

Impedance tolerance: ±5 Ω

across wide thermal and frequency ranges.

| Challenge | Root Cause | Impact |

|---|---|---|

| Phase Drift | Dielectric fluctuation at elevated temperature | Beamforming and calibration deviation |

| Connector Fatigue | Repeated mechanical stress | Micro-cracks, impedance instability |

| Surface Reflection | Resin or conductor mismatch | Calibration uncertainty, S11 increase |

KKPCB mitigates these effects through tight dielectric control, vacuum lamination, and inline 110 GHz RF verification.

2. KKPCB’s Precision RF Manufacturing Framework

a. Controlled Dielectric Uniformity

-

Pre-baked RO5880 laminates (120 °C / 4 h) for moisture removal

-

Vacuum lamination ensuring dielectric thickness tolerance ±8 µm

-

Maintained phase linearity beyond 90 GHz

b. Conductor Surface Optimization

-

½ oz rolled copper with surface roughness Ra < 0.8 µm

-

Reduced conductor loss, achieving insertion-loss deviation < 0.05 dB/inch

c. Inline RF Validation

-

VNA and TDR measurements up to 110 GHz

-

S-parameter and impedance verification for every production lot

-

Full traceability to NIST-calibrated standards

3. Case Study — Ka-Band VNA Calibration Module (40–50 GHz)

Client: European metrology instrumentation OEM

Objective: Develop a phase-critical calibration fixture using RO5880 PCBs for ultra-stable amplitude and low phase drift.

| Parameter | Target | KKPCB Result |

|---|---|---|

| Amplitude Balance | ±0.05 dB | ±0.04 dB |

| Phase Stability | <1° @ 50 GHz | 0.8° |

| Connector Endurance | >500 cycles | <0.3% failure |

| Thermal Range | –55 °C to +125 °C | Stable impedance ±3% |

Engineering Approach:

-

Dual-layer RO5880 PCB stackup bonded with low-flow PTFE prepreg (CTE < 12 ppm/°C)

-

Vacuum lamination: 175 °C / 60 min / 180 psi

-

Embedded phase-compensation microstrip traces verified via 3D EM simulation

-

Inline S-parameter validation up to 110 GHz

Outcome:

Achieved full ISO/IEC 17025 traceability and extended recalibration interval by 35%, confirming RO5880 PCB suitability for long-term metrology use.

4. Long-Term Reliability Validation

To guarantee operational endurance, KKPCB conducts accelerated environmental and mechanical stress testing:

| Test Type | Condition | Result |

|---|---|---|

| Thermal Cycling | –55 °C ↔ +150 °C / 1000 cycles | No delamination; CTE balanced |

| Humidity Exposure | 85 °C / 85 % RH / 1000 h | Df drift < 0.0001 |

| Mechanical Stress | >500 connector insertions | No impedance deviation |

| Panel Flatness | <0.1 mm / 250 mm | Pass |

The combination of RO5880 material integrity and KKPCB’s lamination process ensures stable electrical and mechanical performance even under extreme stress.

5. Engineering Insights

While RO5880 PCB substrates provide industry-leading dielectric stability, they are mechanically softer than ceramic-filled laminates.

KKPCB compensates for this through balanced CTE stackups and stress-relieved cooling profiles, preserving both mechanical planarity and phase linearity.

For OEMs in metrology, satellite communication, and aerospace test systems, this approach guarantees consistent calibration accuracy across extended operation periods.

6. KKPCB’s Quality and Traceability Framework

-

Material Dk/Df verification under controlled humidity

-

3D lamination simulation for CTE balance across RO5880 layers

-

Inline impedance verification up to 110 GHz

-

Accelerated aging and vibration testing (IPC-TM-650 compliant)

-

RF phase stability audits for each production batch

This process ensures every RO5880 PCB achieves repeatable, traceable, and verifiable performance from prototype to volume production.

Conclusion — Turning RF Precision into Production Reliability

RO5880 PCBs set the benchmark for ultra-low-loss and phase-stable performance in mmWave calibration systems.

Through KKPCB’s precision RF manufacturing and reliability validation, engineers achieve calibration modules that:

-

Maintain stable S-parameter responses

-

Deliver phase-locked repeatability

-

Withstand long-term thermal and mechanical loads

KKPCB continues to be the trusted partner for metrology instrumentation, 5G mmWave test systems, and satellite calibration platforms—transforming laboratory precision into scalable, production-grade reliability.