1. The Growing Thermal Challenge in High-Power RF & mmWave Systems

As 5G infrastructure, satellite communication, and automotive radar systems push beyond 24–81 GHz, PCB substrates face new levels of thermal density and mechanical stress.

In these high-frequency environments, heat is not just a byproduct — it’s a design-defining variable that directly influences signal integrity, impedance control, and long-term module reliability.

Rogers RO4003C PCB material, with its Dk of 3.38 ± 0.05 and Df of 0.0027 @ 10 GHz, provides a cost-effective alternative to PTFE-based laminates. Its excellent dimensional stability and consistent dielectric constant make it a preferred choice for high-power amplifiers, phased-array radar, and mmWave transceivers.

However, to truly harness RO4003C’s potential in production, engineers must address two interconnected challenges:

-

Efficient thermal management under power cycling, and

-

Maintaining dimensional stability during lamination and reflow processes.

That’s where KKPCB’s thermal engineering and hybrid lamination expertise come in — transforming thermal instability risks into predictable, production-ready performance.

2. Why Thermal and Dimensional Stability Define Reliability

In RF and mmWave boards, even minor warpage (20–30 µm) or resin flow imbalance can shift antenna phase angles or detune impedance paths.

Thermal failure modes are often cumulative — starting with micro-voids or copper-plane distortion that later manifest as signal loss or phase drift.

| Reliability Concern | Root Cause | Impact |

|---|---|---|

| Hotspot Formation | Uneven copper density or via distribution | Local Dk/Df change, phase distortion |

| Layer Warpage | CTE mismatch between RO4003C and FR-4 | Misalignment, solder joint fatigue |

| Resin Flow Voids | Uncontrolled lamination pressure | Dielectric non-uniformity |

| Reflow-Induced Stress | Rapid heat gradient | Cracking at via transitions |

KKPCB’s process control minimizes these risks through stackup symmetry, heat path simulation, and copper balancing, ensuring both RF performance stability and mechanical reliability.

3. KKPCB’s Thermal Management Approach

(1) Thermal Simulation and Stackup Design

Before fabrication, KKPCB’s design team models heat paths using finite element analysis (FEA) to simulate power dissipation in critical RF regions.

Key techniques:

-

Embedded copper planes below PA (Power Amplifier) zones

-

Via-array thermal channels (0.6 mm pitch, 0.3 mm hole)

-

Balanced layer symmetry to reduce CTE stress

-

Controlled resin flow for consistent dielectric spacing

These steps reduce hotspot delta-T by up to 12–18°C, ensuring long-term thermal reliability.

(2) Precision Lamination for Dimensional Control

RO4003C and FR-4 hybrid stackups introduce a CTE mismatch (≈ 11 ppm/°C vs 17 ppm/°C).

KKPCB uses vacuum-assisted lamination with multi-step temperature ramps to equalize stress distribution.

-

Heating rate < 2°C/min

-

Balanced layup structure to control z-axis expansion

-

180°C / 60 min / 200 psi lamination profile

-

Post-lamination dimensional tolerance within ±0.05%

This ensures copper-to-dielectric alignment within ±8 µm, critical for mmWave array registration.

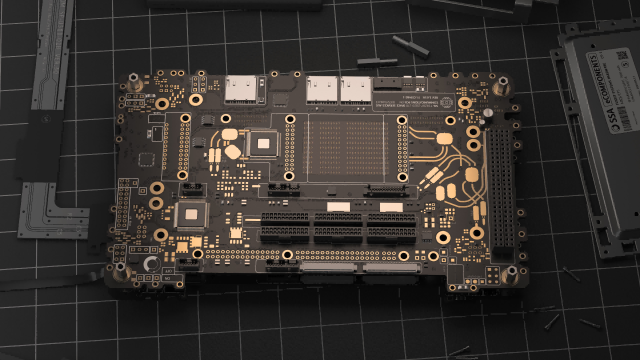

4. Engineering Case Study 1 — Automotive 77 GHz Power Radar Module

Client Background:

A German Tier-1 automotive radar supplier was scaling a 77 GHz front-end module for adaptive cruise control systems.

During pre-production, engineers observed antenna phase drift exceeding 3.2° at 85°C operation — a result of localized heat accumulation near the PA and LNA regions.

Challenges:

-

Hotspot temperatures peaking at 118°C under 2W continuous load

-

0.26 mm board warpage during reflow

-

Inconsistent impedance on inner RF layers (±8%)

KKPCB Engineering Solution:

-

Embedded 1.2 mm copper heat spreader under PA

-

Re-optimized via-array grid (0.6 mm → 0.45 mm) for better heat diffusion

-

Introduced RO4450F low-flow bonding film for CTE balance

-

Modified press cooling rate to <1.5°C/min

Results:

| Parameter | Before | After KKPCB Optimization |

|---|---|---|

| Hotspot Temperature | 118°C | 97°C |

| Phase Drift @ 77 GHz | ±3.2° | ±0.9° |

| Impedance Variation | ±8% | ±3.5% |

| Panel Warpage | 0.26 mm | 0.11 mm |

After 1000 thermal cycles (–40~+125°C), the module passed AEC-Q200 qualification, achieving 99.7% yield stability in volume production.

5. Engineering Case Study 2 — Satellite Transceiver Power Board

Project Background:

An aerospace communication integrator required a dual-channel 30 GHz transceiver board operating under low-pressure vacuum and high thermal load.

The challenge was maintaining planar integrity during repeated bake-out and launch stress simulation.

Engineering Pain Points:

-

Outgassing tolerance < 0.3% (ASTM E595)

-

Continuous operation at +140°C for 1000 hrs

-

Dielectric drift under vacuum environment

KKPCB Solution:

-

Adopted full-RO4003C 4-layer stackup for zero-humidity drift

-

Integrated embedded copper-core zones under RF power stages

-

Conducted lamination with controlled pressure ramping (50 → 200 psi)

-

Vacuum bake-out at 110°C / 4 hr before bonding

Validation Results:

-

Outgassing 0.25% TML, 0.03% CVCM

-

No voids or delamination after 1000 cycles (–55~+125°C)

-

Phase shift < 0.8° @ 30 GHz

-

Passed NASA-grade vibration & thermal shock qualification

This project demonstrated RO4003C’s dimensional reliability in extreme aerospace conditions, reaffirming its suitability for low-loss, high-precision satellite RF systems.

6. Design and Process Best Practices

KKPCB’s engineering insights for maintaining thermal and dimensional stability in RO4003C PCBs:

-

Maintain copper balance across all signal layers to prevent bow/twist

-

Use RO4450F prepreg for hybrid stackups to match CTE and resin flow

-

Avoid >2 lamination cycles to prevent dielectric property drift

-

Conduct thermal shock tests (–55~+125°C) during prototype validation

-

Validate phase stability and impedance at target operating temperature

7. KKPCB’s Advanced Reliability Infrastructure

KKPCB ensures repeatable reliability through comprehensive process control:

-

±3°C plate temperature uniformity during lamination

-

Automated resin-flow & void detection

-

Real-time impedance testing (VNA up to 110 GHz)

-

IPC Class 3 / IATF 16949 certified line

-

Accelerated aging lab for RF thermal validation

Conclusion — From Thermal Design to Reliable Production

RO4003C offers a balanced path between RF precision and manufacturability.

Yet its performance in high-power environments depends heavily on thermal path design, stackup symmetry, and process control.

Through KKPCB’s engineering expertise in thermal simulation, lamination precision, and reliability testing, OEMs can confidently move from prototype to mass production — ensuring stable performance, low thermal stress, and consistent yield in automotive radar, 5G infrastructure, and aerospace communication modules.