Heat Dissipation Challenges in High-Power RF Circuits

As RF and mmWave systems scale beyond 24 GHz, power density and thermal stress become critical limiting factors for system reliability. Engineers designing automotive radar front-ends, 5G transceivers, and satellite payloads must manage high localized temperatures within densely packed multilayer PCBs.

While traditional FR-4 substrates often exhibit resin softening and dielectric drift under heat, Rogers RO4835 PCB provides superior thermal stability (Tg > 280 °C) and oxidation resistance, making it a preferred choice for high-power RF and aerospace systems. However, achieving reliable thermal performance requires more than material selection—it demands precision in stackup design, copper balancing, and via thermal conduction optimization.

RO4835 PCB Thermal Characteristics and Material Advantages

RO4835 PCB is engineered for low dielectric loss (Df = 0.0037 @ 10 GHz) and stable Dk (3.48 ± 0.05) even after 1,000 hours of 150 °C aging. Its oxidation-resistant resin system maintains dielectric stability over extended exposure, reducing loss increase compared to RO4350B and other hydrocarbon-ceramic laminates.

| Parameter | RO4835 | RO4350B | FR-4 |

|---|---|---|---|

| Dk @ 10 GHz | 3.48 ± 0.05 | 3.48 ± 0.05 | 4.2 ± 0.15 |

| Df @ 10 GHz | 0.0037 | 0.0038 | 0.018 |

| Thermal Conductivity (W/m·K) | 0.69 | 0.64 | 0.28 |

| Tg (°C) | > 280 | > 280 | 135–150 |

The improved thermal conductivity and oxidation control make RO4835 a stable platform for power amplifiers, phased array antennas, and radar sensor modules where both thermal management and RF integrity must coexist.

Stackup and Lamination Strategies for Thermal Balance

KKPCB engineers implement hybrid stackups that combine RO4835 dielectric layers with FR-4 or copper cores to achieve both electrical precision and cost efficiency.

Thermal imbalance and CTE mismatch (RO4835 ≈ 11 ppm/°C vs FR-4 ≈ 17 ppm/°C) are mitigated through:

-

Balanced Copper Layering: Symmetrical copper distribution minimizes warpage during lamination and thermal cycling.

-

Stepwise Lamination: Multi-stage press cycles (180 °C / 60 min / 200 psi) with controlled cooling gradients (< 2 °C/min) prevent resin stress cracking.

-

Embedded Copper Coins: In power amplifier boards, localized copper inlays under power devices reduce θJA by up to 20 %.

KKPCB’s hybrid lamination optimization ensures consistent z-axis expansion, maintaining via reliability over 1,000 thermal cycles (–55 °C ↔ +150 °C) with less than 0.5 % delamination occurrence.

Thermal Via, Heat Spreading, and Simulation-Driven Design

RO4835 PCBs used in high-power RF designs often employ via arrays and metal core transitions to facilitate efficient heat conduction from surface components to internal copper planes. KKPCB integrates thermal-electrical co-simulation (via ANSYS Icepak + HFSS) to identify hot-spot concentration and optimize via geometry.

Design Practices for Effective Thermal Dissipation:

-

Via density: ≥ 80 vias/cm² near high-power devices

-

Plated-through-hole (PTH) aspect ratio: < 8:1 for improved heat flow

-

Filled vias (copper or resin): Reduce voiding and maintain planarity for BGA assembly

-

Thermal interface optimization: Integration with AlN or copper baseplates in power modules

Case Example — 28 GHz Power Amplifier Module

A 6-layer RO4835 PCB (0.508 mm core) with 4-oz copper inner layers achieved a 15 °C junction-to-ambient reduction compared to a non-optimized stackup, extending module MTBF by 22 %.

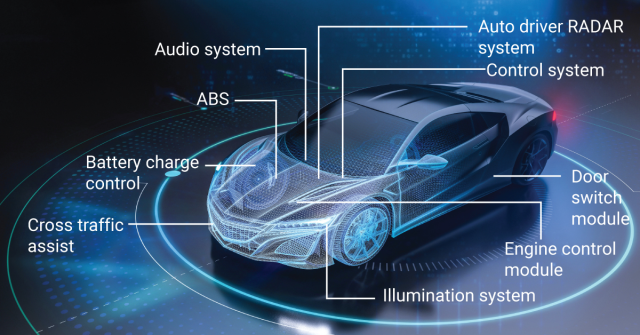

Case Study: 77 GHz Automotive Radar Front-End Module

A Tier-1 radar supplier collaborated with KKPCB to develop a hybrid RO4835 + FR-4 PCB for a 77 GHz radar transceiver module. The system required both low-loss RF routing and effective heat removal for integrated power amplifiers.

| Parameter | Before Optimization | After KKPCB Redesign |

|---|---|---|

| Max Board Warpage | 0.22 mm | 0.13 mm |

| Thermal Resistance (θJA) | 18.6 °C/W | 14.7 °C/W |

| Impedance Stability | ± 7 % | ± 3 % |

| RF Loss (24 GHz) | 0.26 dB/inch | 0.24 dB/inch |

KKPCB’s redesign—featuring thermal vias under PA regions and symmetric stackup alignment—enabled stable RF gain and phase performance even after 500 thermal shock cycles (–55 °C ↔ +125 °C).

Engineering Insights and Conclusion

Thermal management in RO4835 PCBs requires a holistic design approach—integrating material selection, stackup balance, and heat path optimization rather than relying on resin properties alone. KKPCB’s experience in RF thermal simulation, precision lamination, and qualification testing ensures every RO4835 PCB sustains both electrical performance and thermal reliability under high-frequency operation.

-

Simulation-driven thermal optimization up to 110 GHz

-

Hybrid lamination process control (IPC-4103C / IPC-6018)

-

Automotive-grade reliability testing (AEC-Q200, –55 °C ↔ +150 °C)

Partner with KKPCB for your next high-power RF or mmWave project.

Our RF engineering team provides thermal simulation, impedance verification, and stackup co-design support for 5G, automotive, and aerospace applications.

Contact KKPCB Engineering Support to discuss your RO4835 PCB design or request a detailed reliability validation plan.