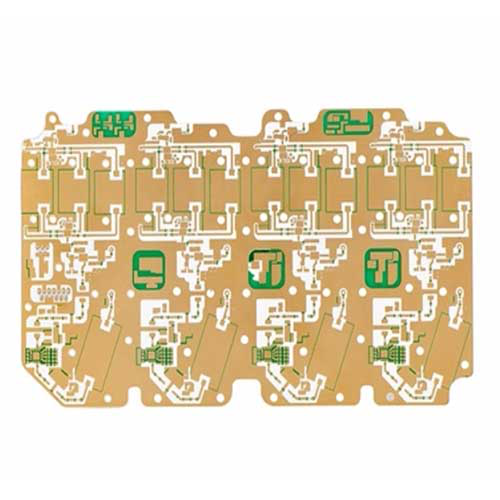

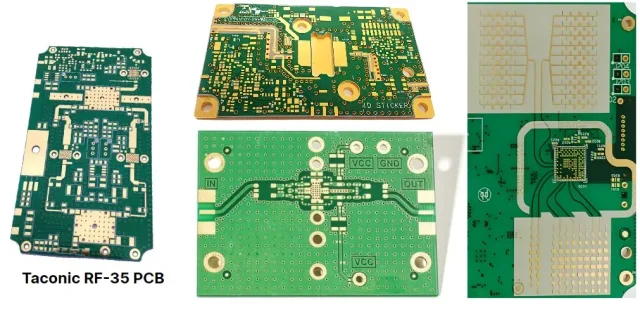

Taconic RF-35 High-Performance Laminates for Precision RF & Microwave PCB Design

In the demanding fields of RF and microwave electronics, every decibel counts. That’s why KKPCB partners with leading material suppliers like Taconic to provide high-performance laminates such as RF-35. This material combines consistency, precision, and low loss to enable next-generation signal performance. Taconic RF-35 features a dielectric constant (Dk) of 3.5 and a dissipation factor (Df) as low as 0.0019, forming a solid foundation for microwave, millimeter-wave, and multi-gigabit digital frequency designs.

What Makes Taconic RF-35 Unique

Taconic RF-35 is a ceramic-filled PTFE composite laminate, offering exceptional thermal stability, dielectric uniformity, and moisture resistance—critical properties for maintaining performance in high-frequency environments.

Key Highlights:

-

Dielectric constant (Er): 3.5 ± 0.05, ensuring tight impedance control

-

Dissipation factor (Df): 0.0019, maintaining minimal insertion loss beyond 10 GHz

-

Moisture absorption: only 0.02%, ensuring excellent environmental stability

-

Z-axis CTE: 82 ppm/°C, closely matched to copper for long-term reliability

-

Thermal conductivity: 0.71 W/mK, enabling efficient heat dissipation

-

Tg > 280°C: fully compatible with lead-free reflow and high-temperature assembly

At KKPCB, we leverage these properties to produce high-frequency PCBs with consistent impedance control, stable performance, and excellent manufacturability across production batches.

RF-35 vs. FR-4 — Why It Matters for High-Frequency Design

Compared to traditional FR-4 laminates, Taconic RF-35 offers superior signal integrity and frequency stability.

| Property | Taconic RF-35 | Standard FR-4 |

|---|---|---|

| Dielectric Constant (Er) | 3.5 ± 0.05 | 4.5 ± 0.25 |

| Dissipation Factor (Df) | 0.0019 | 0.02 |

| Moisture Absorption | 0.02% | 0.2% |

| Frequency Range | Up to Ku-band | <5 GHz |

| Impedance Stability | Excellent | Moderate |

As RF designs move into microwave or millimeter-wave ranges, FR-4 performance begins to degrade. RF-35 maintains low attenuation, tightly controlled Dk, and high Q-factor, making it ideal for 5G base stations, satellite links, and radar systems.

Applications of Taconic RF-35

At KKPCB, we apply RF-35 in a wide range of precision high-frequency PCB projects, including:

-

5G & wireless communication systems: base stations, antennas, routers, RF modules

-

Radar systems: aerospace, defense, automotive radar boards

-

Microwave and millimeter-wave components: filters, couplers, amplifiers, phased-array elements

-

High-speed digital PCBs: network switches, data servers, backplanes

-

Automotive electronics: ADAS radar and in-vehicle communication systems

-

Aerospace & defense: satellite and electronic warfare subsystems

These applications demand the strict dielectric control and moisture resistance of RF-35 to ensure stable performance even in harsh conditions.

Importance of RF-35 in PCB Manufacturing

From a manufacturing perspective, RF-35 simplifies achieving precise impedance control and repeatable process performance. KKPCB’s production team emphasizes:

-

Stable dielectric properties and predictable etching tolerances

-

Consistent inter-layer impedance for multi-layer RF designs

-

Compatibility with standard drilling, plating, and soldering processes

-

Excellent yield and repeatability for production-scale runs

Combined with KKPCB’s advanced process control, RF-35 boards meet stringent frequency and impedance targets from prototype to mass production.

Considerations When Using Taconic RF-35

When specifying RF-35 laminates, KKPCB engineers carefully evaluate:

-

Target operating frequency range

-

Stack-up design and dielectric thickness

-

Impedance control requirements

-

Manufacturing process compatibility

-

Environmental exposure and long-term stability

Proper material selection and stack-up engineering are critical to fully leverage RF-35 performance. KKPCB provides simulation-based design support to ensure your final PCB achieves optimal results.

Why Choose KKPCB for Taconic RF-35 PCBs?

With years of RF and microwave PCB manufacturing experience, KKPCB is a trusted partner for global clients seeking precision, low-loss, and highly stable PCB solutions.

KKPCB offers:

-

Deep expertise in RF and millimeter-wave PCB stack-up design

-

Proven compatibility with Taconic, Rogers, and Isola laminates

-

Custom thickness and shape options—round, rectangular, or complex RF geometries

-

High-quality surface finishes (ENIG, immersion silver, lead-free HASL)

-

Comprehensive electrical testing and impedance verification before shipment

Whether you’re developing radar modules, 5G infrastructure, or advanced RF sensors, KKPCB delivers not only materials but also engineering precision and manufacturing excellence.

Conclusion

Taconic RF-35 represents an ideal balance of low dielectric loss, environmental resilience, and manufacturability. In the hands of skilled engineers, it unlocks performance unattainable with traditional laminates. At KKPCB, we transform this material’s potential into real-world RF and microwave PCB solutions, ensuring your designs achieve the signal integrity, reliability, and repeatability required for today’s high-frequency applications.

Partner with KKPCB to explore how Taconic RF-35 can elevate your next high-frequency PCB design to new levels of precision and performance.