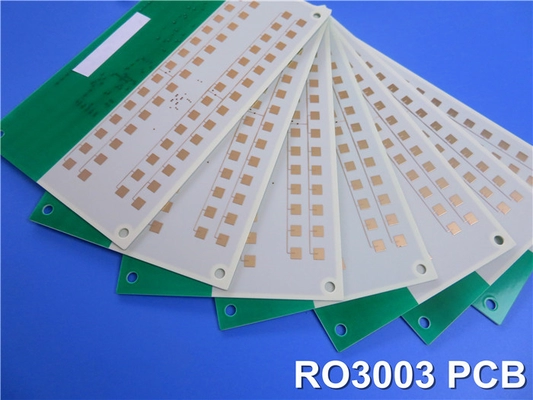

Rogers RO3003 PCB is one of the most advanced high-frequency circuit board materials available today. Designed with a ceramic-filled PTFE composite, this substrate delivers exceptional electrical, thermal, and mechanical performance, making it a preferred choice for engineers developing RF, microwave, and high-speed communication systems.

At KKPCB, we specialize in manufacturing custom Rogers RO3003 PCBs, providing high reliability and precision solutions for demanding electronic applications.

1. Overview of Rogers RO3003 High Frequency Materials

Rogers RO3003 is part of the RO3000™ series developed for commercial microwave and RF applications. It features a stable dielectric constant (Dk = 3.0 ±0.04) and an ultra-low dissipation factor (Df = 0.001), ensuring minimal signal distortion and low transmission loss even at frequencies above 20 GHz.

Unlike typical PTFE-based materials, RO3003 offers superior dimensional stability due to its CTE (Coefficient of Thermal Expansion) of 17 ppm/°C in the X and Y axes, which closely matches copper. This compatibility ensures excellent layer-to-layer registration and via reliability, even in thermally demanding environments.

2. Key Material and Electrical Properties

| Property | Typical Value | Units | Condition/Test Method |

|---|---|---|---|

| Dielectric Constant (εr) | 3.0 ±0.04 | — | 10 GHz / 23°C, IPC-TM-650 2.5.5.5 |

| Dissipation Factor (tan δ) | 0.001 | — | 10 GHz / 23°C |

| Thermal Conductivity | 0.5 | W/m·K | 50°C, ASTM D5470 |

| Volume Resistivity | 1×10⁷ | MΩ·cm | IPC 2.5.17.1 |

| CTE (X/Y/Z) | 17 / 17 / 24 | ppm/°C | -55°C to 288°C |

| Moisture Absorption | 0.04 | % | IPC-TM-650 2.6.2.1 |

| Flammability Rating | UL 94 V-0 | — | UL Standard |

| Glass Transition Temperature (Tg) | >280°C | — | — |

These parameters ensure low signal loss, high heat resistance, and outstanding mechanical reliability, which are essential for RF and microwave circuit integrity.

3. KKPCB RO3003 PCB Construction & Manufacturing Capability

| Specification | Details |

|---|---|

| Material | Rogers RO3003, Ceramic-filled PTFE |

| Dielectric Constant (Dk) | 3.0 |

| Dissipation Factor (Df) | 0.001 |

| Thickness | 60 mil / 1.524 mm / 2.27 mm (Customizable) |

| Copper Foil | 18 μm (0.5 oz) / 35 μm (1 oz) |

| Surface Finish | ENIG (Immersion Gold, 1 µm) |

| Layers | 2–6 layers |

| Min. Trace / Space | 5 mil / 5 mil |

| Min. Drill Hole | 0.2 mm |

| Blind/Buried Via Support | DRL3–4 |

| Final PCB Thickness | 1.6 mm ±10% |

| Testing | 100% Electrical Test |

| Flammability | UL 94 V-0 |

| Finish Color | Optional – bare or white silkscreen |

High-Precision Surface Finish

The ENIG (Electroless Nickel Immersion Gold) finish guarantees excellent solderability, oxidation resistance, and low contact resistance—ideal for high-frequency signal integrity and reliable long-term performance.

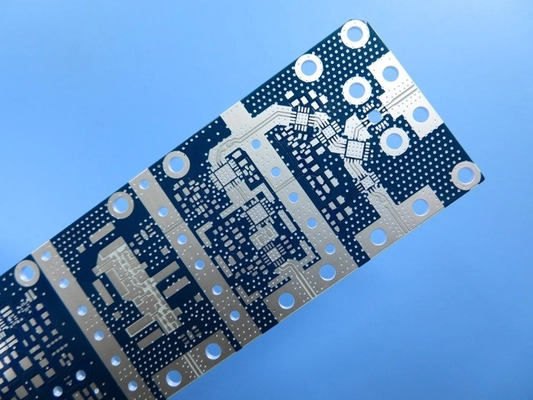

Micro-Via & Blind Hole Technology

With minimum drilling size of 0.2mm, KKPCB’s precision drilling technology supports HDI and multi-layer RF PCB structures, enabling compact, high-density interconnect designs.

4. Thermal and Mechanical Stability

Rogers RO3003 offers exceptional mechanical strength and thermal stability, making it reliable for both static and dynamic environments:

-

High Tg (>280°C) ensures consistent dielectric behavior under high thermal stress.

-

Low Z-axis expansion (24 ppm/°C) ensures reliable plated through-holes (PTH) and prevents delamination.

-

Dimensional stability (<0.07 mm/m) maintains layer alignment during fabrication and reflow processes.

This ensures consistent impedance control, minimal signal phase shift, and superior reliability across temperature ranges from -55°C to +150°C.

5. Applications of Rogers RO3003 PCB

1. RF and Microwave Systems

Ideal for power amplifiers, low noise amplifiers (LNA), RF switches, and filters, where stable dielectric properties ensure precise signal performance.

2. Automotive Electronics

Used in radar sensors, vehicle communication modules, and ADAS systems, providing reliable signal transmission in high-temperature environments.

3. Wireless Communication & Antennas

Perfect for GPS antennas, patch antennas, 5G base stations, and wireless transmitters, supporting stable, low-loss RF propagation.

4. Aerospace & Defense

RO3003 PCBs are widely adopted in satellite communication, radar systems, and navigation modules, where low loss, mechanical robustness, and thermal reliability are essential.

5. Data & Broadcast Systems

Applied in direct broadcast satellites (DBS) and data link over cable systems, ensuring precise signal phase control and low insertion loss.

6. Advantages of Rogers RO3003 PCB from KKPCB

✅ Low Loss & High Signal Integrity

Low Dk and Df values minimize signal attenuation, providing clear, stable transmission for GHz-level circuits.

✅ Excellent Heat Resistance

High Tg and CTE matching with copper ensure minimal warpage, ideal for reflow and lead-free soldering processes.

✅ Superior Reliability

ENIG finish enhances corrosion resistance and contact quality for long-term field performance.

✅ Supports Multi-Layer & Compact Designs

Blind/buried vias and precision drilling enable compact, high-density, multi-layer RF designs.

✅ Wide Frequency Range

Stable electrical performance from 8 GHz up to 40 GHz, suitable for advanced microwave and mmWave applications.

7. KKPCB – Professional Manufacturer for High-Frequency & RF PCBs

At KKPCB, we provide one-stop PCB manufacturing and assembly solutions for high-frequency applications.

Our factory is equipped with advanced lamination, drilling, and laser equipment, ensuring tight impedance control, precise registration, and zero-defect quality assurance.

We Process Various High-Frequency Materials:

-

Rogers: RO3003, RO4003C, RO4350B, RO4835, RO5880

-

Taconic: RF-35, TLY-5, TSM-DS3

-

Isola: I-Tera MT40, Astra MT77

-

F4B, TP-2, FR4: for hybrid and cost-effective designs

Dielectric Constant Range:

From 2.2 to 10.6, supporting custom impedance-controlled designs for high-speed and high-reliability circuits.