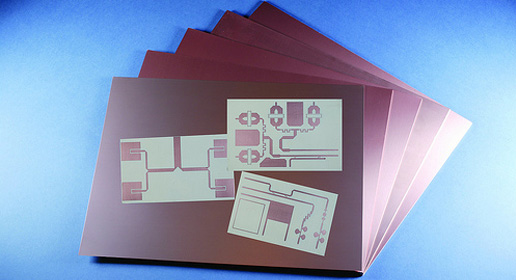

RO4835™ laminates are engineered to provide low loss, outstanding stability, and extended durability in demanding RF and microwave applications. These materials are specifically designed for high-frequency circuits, offering superior performance and compatibility with standard FR-4 PCB processing techniques.

Key Features

- Enhanced Thermal Stability:

- Superior resistance to oxidation, ensuring long-term reliability.

- Low Dissipation Factor (Df):

- Consistent performance across a wide frequency range.

- Excellent Dimensional Stability:

- Ideal for multilayer designs requiring precise alignment.

- FR-4 Compatibility:

- Compatible with standard processing, enabling cost-effective fabrication.

- Low Moisture Absorption:

- Ensures reliable performance in humid environments.

Material Properties

| Property | Typical Value | Unit |

|---|---|---|

| Dielectric Constant (Dk) | 3.48 ± 0.05 | @ 10 GHz |

| Dissipation Factor (Df) | 0.0037 | @ 10 GHz |

| Thermal Conductivity | 0.66 | W/m·K |

| Glass Transition Temperature (Tg) | >280 | °C |

| Thermal Decomposition (Td) | 425 | °C |

| Moisture Absorption | <0.1% | % |

| Peel Strength | ≥1.05 | N/mm |

Applications

- 5G Infrastructure: High-frequency laminates for base stations and antennas.

- Automotive Radar: Advanced driver-assistance systems (ADAS).

- Aerospace and Defense: Mission-critical RF and microwave systems.

- IoT Devices: Reliable circuits for sensors and communication modules.

Processing Guidelines

1. Drilling and Hole Preparation

- Use carbide drills with optimized parameters for precise hole formation.

- Clean vias using plasma etching or desmearing to remove debris.

2. Lamination

- Laminate under pressures of 200–400 psi and temperatures of 425–450°F (220–230°C).

3. Etching and Plating

- Compatible with conventional copper etching techniques.

- Maintain controlled environments for accurate feature definition.

4. Surface Finishes

- Supports multiple surface finishes, including ENIG, immersion silver, and OSP.

Advantages of RO4835 Laminates

- Long-Term Stability:

- Exceptional resistance to environmental degradation, extending operational lifespans.

- Versatile Design Compatibility:

- Suitable for hybrid designs integrating multiple material types.

- Cost-Effective Processing:

- Eliminates the need for specialized fabrication processes.

- Enhanced Thermal Management:

- Effective heat dissipation for high-power designs.

Available Configurations

- Thickness Options: Multiple options for optimized circuit designs.

- Copper Cladding: Available in various weights of rolled or electrolytic copper.

RO4835™ laminates provide an optimal balance of electrical, thermal, and mechanical properties, making them the material of choice for high-frequency PCB designers. These laminates support the development of reliable, efficient, and scalable RF and microwave applications.