In high-frequency electronics, the choice of PCB material directly determines the performance, stability, and reliability of the end product. With the rapid rise of 5G communication, automotive radar, aerospace, and microwave systems, PCB manufacturers are increasingly adopting hybrid PCB solutions to balance electrical performance and cost efficiency.

Among these, the Rogers RO4835 + IT180 Hybrid PCB stands out as one of the most practical and reliable solutions, combining the proven high-frequency performance of Rogers RO4835 with the mechanical stability and cost advantages of IT180.

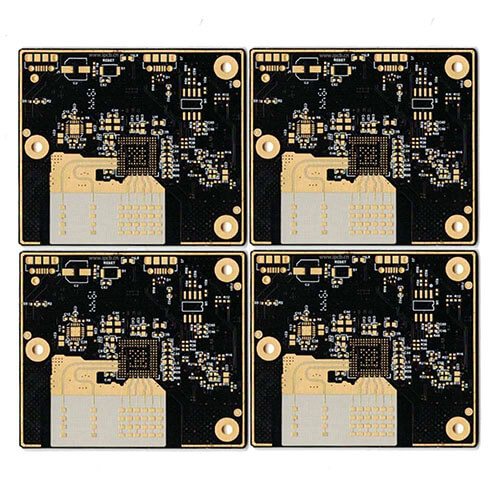

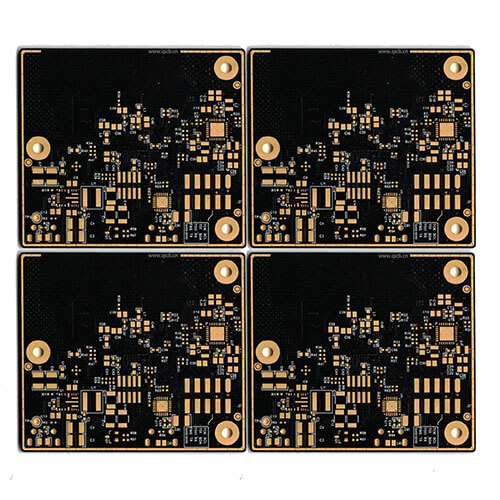

Overview of Rogers RO4835 + IT180 Hybrid PCB

The hybrid design strategically uses Rogers RO4835 in critical RF layers, while IT180 FR-4 is applied in non-RF layers. This approach ensures signal integrity in high-frequency circuits while controlling overall production costs.

Technical Specifications:

-

Material Composition: Rogers RO4835 + IT180

-

Layer Count: 6 layers (expandable for HDI and multilayer designs)

-

Board Thickness: 1.5 mm

-

Copper Thickness: 1 oz finished copper

-

Impedance Control: 50 ohms

-

Dielectric Thickness: 0.127 mm

-

Dielectric Constant (Dk): 3.48 ±0.05 (at 10 GHz)

-

Dissipation Factor (Df): 0.0037 (low loss)

-

Thermal Conductivity: 0.69 W/m·K

-

CTE Stability: Low X/Y axis expansion, compatible with high-layer builds

-

Flammability Rating: UL 94V-0

-

Surface Finish: Immersion Gold / ENIG

Key Advantages of Rogers RO4835 + IT180 Hybrid PCB

1. Superior High-Frequency Performance

- Low Dk and Df provide excellent signal integrity.

- Ensures low insertion loss and minimal signal distortion at GHz-level frequencies.

- Ideal for 77 GHz automotive radar, 5G antennas, RF front-end modules, and satellite communication.

2. Excellent Thermal and Oxidation Resistance

- Rogers RO4835 integrates oxidation inhibitors, offering 10× longer oxidation resistance than conventional thermoset laminates.

- Ensures long-term stability in high-temperature and outdoor environments.

3. Balanced Cost-Performance Ratio

- Hybrid design minimizes the use of expensive Rogers material.

- IT180 provides mechanical strength and cost savings without affecting electrical performance.

4. Enhanced Manufacturability

- Compatible with standard PCB fabrication processes.

- Supports blind/buried vias, HDI structures, and controlled impedance routing.

- Stable dimensional performance reduces warpage risk in multilayer builds.

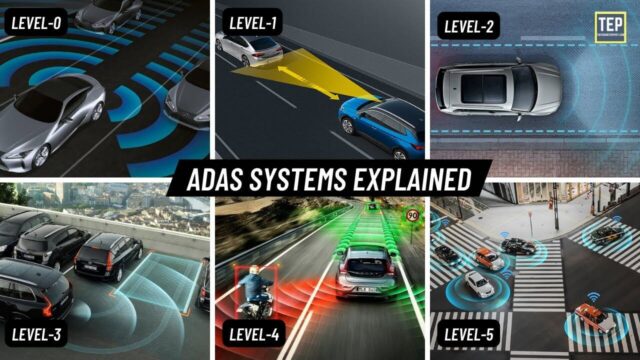

Applications of Rogers RO4835 + IT180 Hybrid PCB

Automotive Electronics

-

77 GHz radar modules for ADAS (Advanced Driver Assistance Systems).

-

Key functions: collision avoidance, adaptive cruise control, blind spot detection, and lane-keeping assistance.

-

High reliability under automotive thermal cycling and vibration stress.

5G & Wireless Infrastructure

-

Low-loss design supports antenna arrays, base stations, RF filters, and power amplifiers.

-

Ensures low latency and high throughput, critical for 5G network rollout.

Aerospace & Defense

-

Stable high-frequency performance under harsh environmental conditions.

-

Suitable for satellite communication, phased array radar, and military RF equipment.

Microwave & RF Communication

-

Provides low insertion loss and stable impedance control for microwave circuits.

-

Applied in backhaul communication links, RF testing boards, and IoT RF modules.

- Automotive Radar Systems: The 77 GHz automotive radar is critical for modern ADAS and autonomous driving systems. Rogers RO4835 + IT180 hybrid PCB ensures that radar systems operate with minimal signal loss and high accuracy, providing reliable real-time performance for vehicle safety and automation.

- Advanced Driver-Assistance Systems (ADAS): These systems rely heavily on sensors and radar, which require stable, high-frequency PCB materials for real-time processing. Rogers RO4835 + IT180 ensures that radar sensors in ADAS remain operational under demanding conditions, providing accurate data for collision avoidance, lane-keeping, and emergency braking systems.

- Wireless Communication Systems: The hybrid PCB solution is ideal for 5G wireless communication infrastructure, which requires low-loss materials for high-frequency signal transmission. The Rogers RO4835 + IT180 hybrid PCB offers outstanding performance in communication systems, ensuring high data throughput and low latency, critical for next-generation wireless technology.

- Microwave and RF Applications: For microwave communication, radar applications, and aerospace technologies, the combination of Rogers RO4835 and IT180 ensures superior performance and reliability in high-frequency environments. The low loss and high thermal stability make this hybrid PCB the preferred choice for high-precision radar and communication systems in harsh environments.

Comparison with Other PCB Materials

| Property | Rogers RO4835 + IT180 Hybrid | FR-4 Only | Pure Rogers RO4350B/RO4003C |

|---|---|---|---|

| High-frequency loss | Very low | High | Very low |

| Cost efficiency | Balanced (hybrid) | Low | Higher cost |

| Thermal management | Good | Limited | Excellent |

| Oxidation resistance | High | Low | Moderate |

| Manufacturability | High (standard process) | High | Requires special handling |

This comparison highlights why RO4835 + IT180 hybrid PCBs are increasingly chosen for projects needing performance and affordability.

Why Choose Rogers RO4835 + IT180 Hybrid PCB?

-

Optimized for GHz-level applications such as automotive radar, 5G, aerospace, and microwave systems.

-

Combines Rogers’ dielectric stability with IT180’s mechanical robustness.

-

Ensures long-term durability, reduced signal loss, and thermal stability.

-

Provides cost-effective solutions without sacrificing high-frequency performance.

Conclusion

The Rogers RO4835 + IT180 Hybrid PCB is a proven solution for next-generation high-frequency electronics. With stable dielectric properties, high oxidation resistance, and excellent manufacturability, it enables advanced applications in automotive, telecom, aerospace, and defense industries.

For designers and engineers seeking reliable, cost-effective, and high-performance PCB materials, the Rogers RO4835 + IT180 hybrid solution remains one of the most trusted options in the high-frequency PCB market.