What Are Hybrid PCB Materials?

Hybrid PCB materials refer to multilayer PCB constructions that combine two or more different laminate materials within the same stack-up.

Instead of using a single material throughout the board, hybrid PCB designs integrate materials such as:

-

Standard FR-4

-

High TG materials

-

Low loss laminates

-

High frequency laminates (Rogers, PTFE, etc.)

This approach allows engineers to balance electrical performance, thermal stability, and cost efficiency within one PCB.

Hybrid PCB materials are widely used in:

-

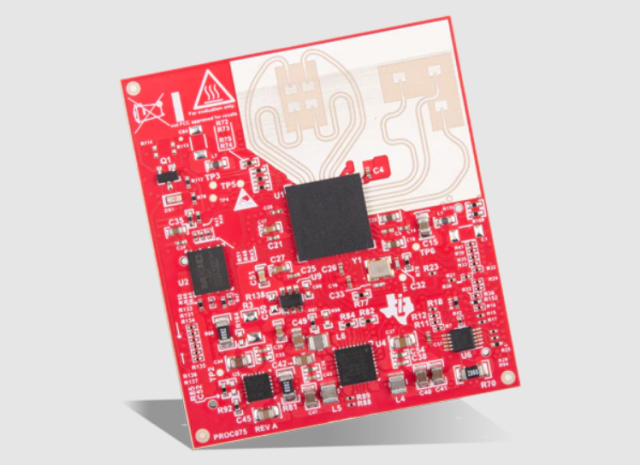

RF and microwave PCB

-

5G communication PCB

-

Automotive radar systems

-

Mixed signal PCB

-

High speed digital + RF combo boards

Why Use Hybrid PCB Materials?

Modern electronic systems often combine:

-

High speed digital signals

-

RF/microwave circuits

-

Power management sections

-

High current circuits

Using only high frequency laminate for the entire PCB would increase cost significantly.

Hybrid PCB materials allow designers to:

-

Use high frequency laminates only where needed

-

Use FR-4 for non-critical layers

-

Optimize material cost

-

Maintain signal integrity

-

Improve overall reliability

This makes hybrid PCB construction a smart solution for performance-driven applications.

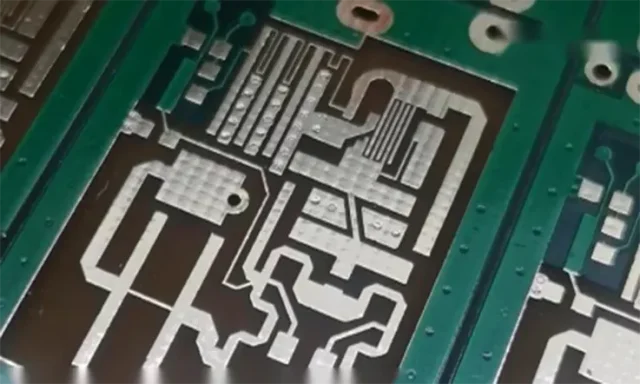

Common Hybrid PCB Material Combinations

FR-4 + Rogers (RO4003C / RO4350B)

-

Popular for RF + digital mixed boards

-

Cost-effective performance solution

FR-4 + PTFE

-

Used in microwave and mmWave designs

-

Excellent low loss performance

High TG FR-4 + Low Loss Material

-

Used in automotive and high speed systems

-

Improved thermal and electrical performance

Ceramic + Organic Laminate

-

Used in high power and high reliability applications

Advantages of Hybrid PCB Materials

Cost Optimization

Only critical signal layers use premium laminates.

Improved Signal Integrity

High frequency layers ensure low insertion loss and stable impedance.

Thermal Stability

High TG or specialty materials improve reliability.

Design Flexibility

Engineers can customize stack-up based on performance requirements.

Applications of Hybrid PCB Materials

Hybrid PCB materials are commonly used in:

-

5G base station PCB

-

RF transceiver PCB

-

Automotive radar PCB

-

High speed networking PCB

-

Satellite communication PCB

-

Mixed signal IC test boards

-

Semiconductor load boards

In these applications, combining multiple material systems ensures both electrical performance and structural stability.

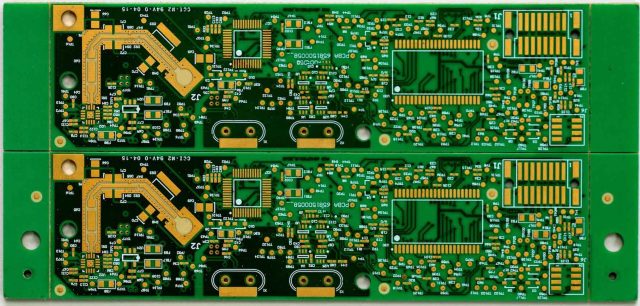

Manufacturing Challenges of Hybrid PCB Materials

Hybrid PCB fabrication requires advanced process control, including:

-

Precise lamination cycle management

-

CTE matching between materials

-

Controlled impedance verification

-

Accurate drilling for mixed dielectric stacks

-

Careful resin flow control

Improper material matching may cause:

-

Delamination

-

Warpage

-

Via reliability issues

Therefore, selecting an experienced hybrid PCB manufacturer is critical.

Why Choose a Professional Hybrid PCB Supplier

A reliable hybrid PCB supplier should provide:

-

Custom stack-up design support

-

Material compatibility evaluation

-

Controlled impedance simulation

-

High layer count capability

-

RF and high speed PCB expertise

Hybrid PCB materials are ideal for applications requiring both high performance and cost control in a single board design.