What Are High Frequency Laminates?

High Frequency Laminates are specialized PCB base materials engineered for high-speed and high-frequency electronic applications. Unlike standard FR-4 materials, high frequency laminates offer:

-

Low dielectric constant (Low Dk)

-

Low dissipation factor (Low Df)

-

Stable electrical performance at GHz frequencies

-

Excellent signal integrity

-

Reliable controlled impedance performance

High frequency laminates are widely used in:

-

RF PCB design

-

Microwave circuits

-

5G communication modules

-

Automotive radar systems

-

Satellite and aerospace electronics

-

High-speed digital systems

As communication technology evolves, selecting the right high frequency laminate is critical for maintaining performance and minimizing signal loss.

Key Properties of High Frequency Laminates

High frequency laminates are designed to ensure stable performance in demanding applications.

Low Dielectric Constant (Dk)

A stable and predictable Dk ensures accurate impedance control and consistent signal transmission.

Low Dissipation Factor (Df)

Low Df minimizes signal attenuation, especially in microwave and mmWave frequencies.

Thermal Stability

High Tg and low CTE improve reliability under thermal cycling.

Dimensional Stability

Essential for fine line and high density PCB fabrication.

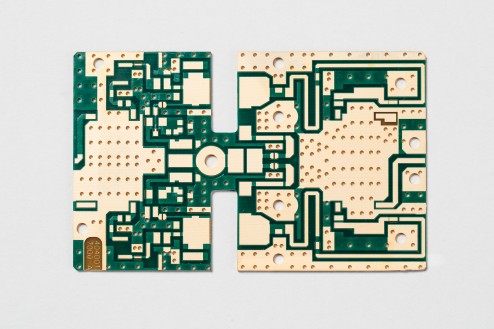

Types of High Frequency Laminates

Several material systems are commonly used as high frequency laminates:

PTFE-Based Laminates

-

Extremely low loss

-

Ideal for microwave and mmWave applications

-

Used in radar and satellite PCB

Hydrocarbon Ceramic Laminates

-

Lower cost compared to pure PTFE

-

Good balance between performance and manufacturability

-

Widely used in 5G PCB designs

Modified Epoxy High Frequency Laminates

-

Enhanced performance compared to FR-4

-

Suitable for high-speed digital applications

Popular High Frequency Laminate Materials

Common high frequency laminates include:

-

Rogers RO4003C

-

Rogers RO4350B

-

RO5880

-

Taconic RF-35

-

TLY-5

-

PTFE composite laminates

Each high frequency laminate offers different Dk, Df, and thermal characteristics tailored for specific RF and microwave applications.

High Frequency Laminates vs Standard FR-4

| Feature | High Frequency Laminates | FR-4 |

|---|---|---|

| Signal Loss | Very Low | Higher |

| Impedance Stability | Excellent | Moderate |

| Frequency Range | GHz to mmWave | Limited |

| Cost | Higher | Lower |

| RF Suitability | Excellent | Limited |

For RF PCB and microwave PCB applications, high frequency laminates significantly outperform standard materials.

Applications of High Frequency Laminates

High frequency laminates are used in:

-

5G base station PCB

-

mmWave antenna PCB

-

Automotive radar PCB

-

RF transceiver PCB

-

Satellite communication PCB

-

High-speed backplane PCB

-

IoT RF module PCB

For high frequency signal PCB and controlled impedance PCB designs, these laminates ensure minimal signal degradation.

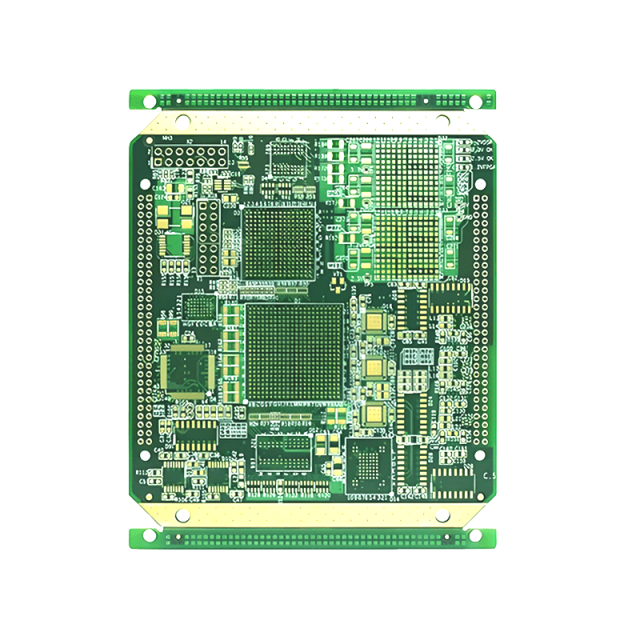

Manufacturing Considerations for High Frequency Laminates

Fabricating PCB with high frequency laminates requires:

-

Precise impedance control

-

Tight thickness tolerance

-

Controlled copper roughness

-

Accurate drilling and plating

-

Clean lamination processes

High frequency laminate PCB manufacturing demands specialized process control to maintain consistent RF performance.

Why Choose the Right High Frequency Laminate Supplier

A professional high frequency laminate supplier provides:

-

Stable material sourcing

-

Multiple laminate options

-

Technical material selection support

-

Controlled impedance testing

-

Prototype and volume production capability

Selecting the correct high frequency laminate is essential for ensuring signal integrity and long-term reliability in advanced communication systems.