What Is a Test Socket PCB for IC?

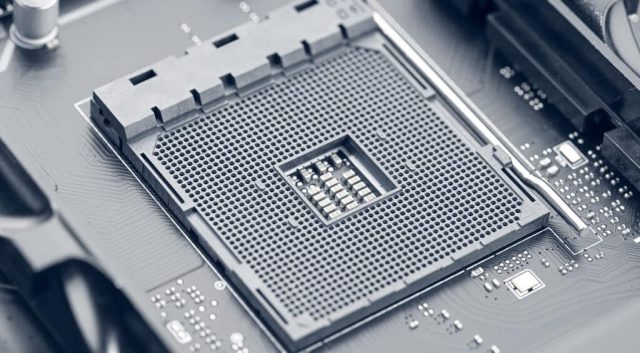

A Test Socket PCB for IC is a specialized printed circuit board designed to mount and support IC test sockets used in semiconductor testing. It acts as the electrical and mechanical interface between the integrated circuit (IC) and automated test equipment (ATE), enabling accurate functional, parametric, and performance testing.

Test socket PCBs are widely used in final test, system-level test, and engineering validation, where repeatable contact, signal integrity, and mechanical durability are critical.

Role of Test Socket PCB in IC Testing

The test socket PCB performs several essential functions:

-

Provides stable mechanical mounting for IC test sockets

-

Routes high-speed and high-frequency signals between IC and ATE

-

Supports controlled impedance transmission lines

-

Delivers clean power and ground to the device under test

-

Enables repeated insertion and removal of ICs during test cycles

As IC packages become denser and faster, the performance of the test socket PCB directly impacts test accuracy and yield.

Key Requirements for Test Socket PCB for IC

Compared to standard PCBs, test socket PCBs must meet stricter requirements:

-

High pin count support for advanced IC packages

-

Fine pitch routing for BGA, LGA, QFN, and custom packages

-

Controlled impedance PCB design for high-speed signals

-

Low crosstalk and low skew routing

-

Excellent flatness and warpage control

-

High mechanical reliability for long test life

These requirements make test socket PCBs a critical component in semiconductor testing systems.

Design Considerations

Effective test socket PCB design includes:

-

Optimized multilayer stackup with solid power and ground planes

-

Short and symmetrical signal paths to minimize parasitics

-

Impedance-controlled routing for high-speed interfaces

-

Robust via design to reduce signal discontinuities

-

Reinforced socket mounting areas to withstand mechanical stress

Close collaboration between PCB engineers, socket suppliers, and test engineers is essential.

Materials Used for Test Socket PCB

Material selection depends on signal speed and test conditions:

-

High-TG FR-4 for standard IC testing

-

Low Dk / Low Df materials for high-speed and high-frequency ICs

-

Hybrid stackups combining FR-4 and low-loss laminates

-

High-reliability prepregs for dimensional stability

For high-speed test socket PCB designs, low-loss materials help maintain signal integrity and timing accuracy.

Manufacturing Capabilities

A professional test socket PCB manufacturer should support:

-

Multilayer PCB fabrication (often 8–20+ layers)

-

HDI technology for dense routing

-

Controlled impedance manufacturing and testing

-

Tight tolerance drilling and registration

-

High-quality surface finishes such as ENIG or ENEPIG

Precision manufacturing ensures consistent electrical and mechanical performance.

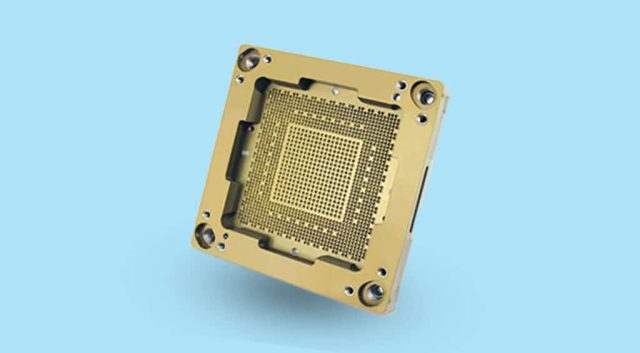

Assembly Considerations

Test socket PCB assembly typically includes:

-

Mounting of IC test sockets

-

Installation of high-speed connectors

-

Assembly of passive components for signal conditioning

-

Mechanical reinforcement for socket retention

Accurate assembly is essential to ensure reliable contact and long service life under repeated test cycles.

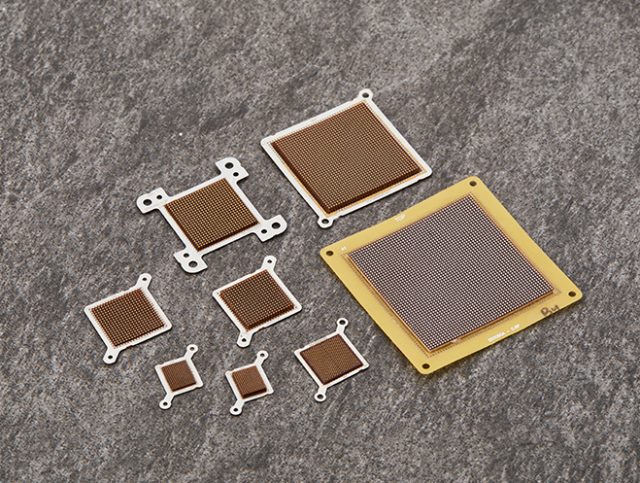

Applications of Test Socket PCB for IC

Test socket PCBs are commonly used in:

-

Final test load boards

-

System-level test PCB

-

Logic IC and processor testing

-

Memory test PCB for DRAM and NAND

-

RF and mixed-signal IC testing

They are a key element in high-volume semiconductor production testing.

Why Choose a Specialized Test Socket PCB Supplier

An experienced test socket PCB supplier offers:

-

Deep understanding of IC testing requirements

-

Optimized stackup and impedance control

-

Stable quality for repeated test cycles

-

Fast prototype and small batch support

-

Engineering support from design review to assembly

Choosing the right partner helps improve test accuracy, reduce downtime, and extend socket life.