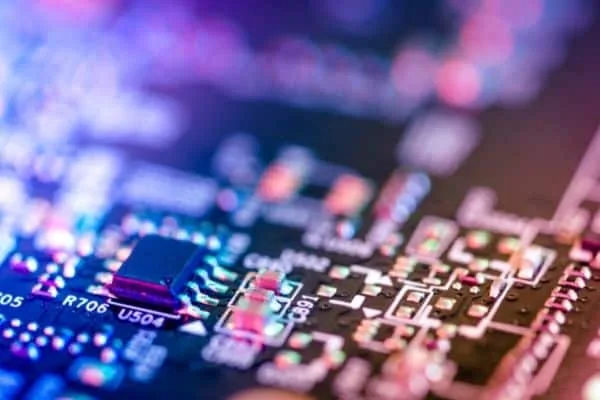

In today’s fast-paced electronics industry, fast delivery PCB services are essential for companies facing tight development schedules, urgent testing requirements, or accelerated product launches. Whether for PCB prototypes, engineering validation, or short-run production, fast delivery PCBs help engineers reduce time-to-market without sacrificing quality.

A reliable fast delivery PCB manufacturer combines efficient engineering processes, advanced fabrication equipment, and streamlined logistics to meet aggressive lead times.

What Is a Fast Delivery PCB?

A fast delivery PCB refers to printed circuit boards manufactured with significantly shortened lead times compared to standard production cycles. These PCBs are commonly used in rapid prototyping, design verification, ATE testing, and urgent customer orders.

Fast delivery does not mean lower standards. High-quality fast delivery PCBs still require strict process control, electrical testing, and dimensional accuracy.

Key Features of Fast Delivery PCB Manufacturing

Quick Turnaround Time

Fast delivery PCB services typically offer lead times from 24 hours to a few days, depending on board complexity and layer count.

Prototype and Small Batch Support

Fast delivery PCBs are ideal for prototype builds, engineering samples, and small batch production before mass manufacturing.

Engineering Review and DFM Optimization

Experienced PCB engineers perform rapid design checks to identify potential issues early, ensuring manufacturability and avoiding delays.

Consistent Quality Control

Despite shorter lead times, fast delivery PCB manufacturing includes AOI, electrical testing, and impedance verification when required.

Fast Delivery PCB Design Considerations

To achieve fast delivery without delays, PCB designs should consider:

-

Standard material availability

-

Reasonable trace width and spacing

-

Optimized stack-up and layer count

-

Controlled impedance planning

-

Clear fabrication notes and documentation

Designs aligned with fast delivery processes help maximize speed and success rates.

Materials Used for Fast Delivery PCBs

Fast delivery PCB manufacturing commonly uses readily available materials such as:

-

Standard and high-Tg FR-4

-

Low-loss laminates for high-speed designs

-

Copper thickness options optimized for quick processing

Material availability plays a critical role in achieving fast delivery timelines.

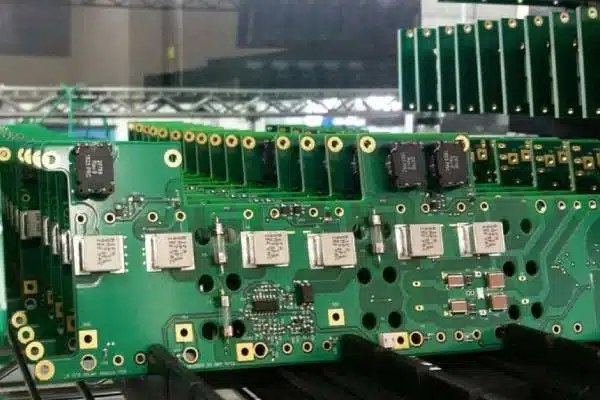

Manufacturing Capabilities for Fast Delivery PCBs

Advanced PCB factories support fast delivery through:

-

Automated drilling and imaging systems

-

High-speed lamination processes

-

In-house electrical testing

-

Parallel production lines for urgent orders

These capabilities allow fast delivery PCB orders to move through fabrication efficiently.

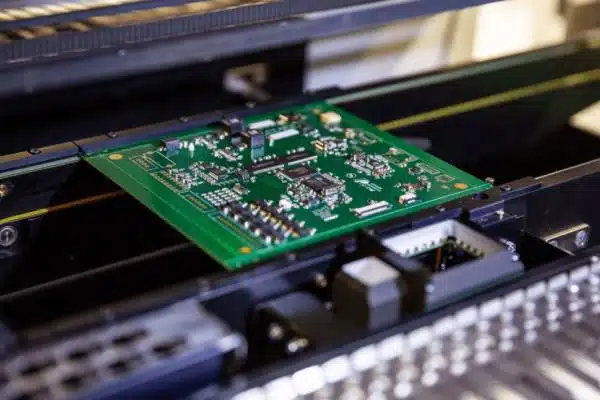

Fast Delivery PCB Assembly

In addition to fabrication, many manufacturers offer fast delivery PCB assembly, including:

-

SMT and through-hole assembly

-

High pin count and fine-pitch components

-

Rapid sourcing of common components

-

Functional and continuity testing

Fast assembly services further reduce overall project lead time.

Applications of Fast Delivery PCBs

Fast delivery PCBs are widely used in:

-

PCB prototype development

-

ATE and semiconductor testing

-

R&D validation and debugging

-

Emergency replacement boards

-

Short lead-time customer projects

These applications demand speed, flexibility, and reliability.

Why Choose a Fast Delivery PCB Supplier?

An experienced fast delivery PCB supplier offers:

-

Short and predictable lead times

-

Engineering support for urgent designs

-

Stable quality across quick-turn orders

-

Scalable production from prototype to volume

This ensures fast delivery PCBs meet both schedule and performance requirements.

Conclusion

Fast delivery PCB manufacturing is a critical service for companies operating under tight timelines. By combining rapid fabrication, reliable quality control, and engineering expertise, fast delivery PCB solutions enable faster product development and smoother project execution.

Choosing the right fast delivery PCB manufacturer helps you stay competitive without compromising performance or reliability.