What Is Small Batch PCB Manufacturing?

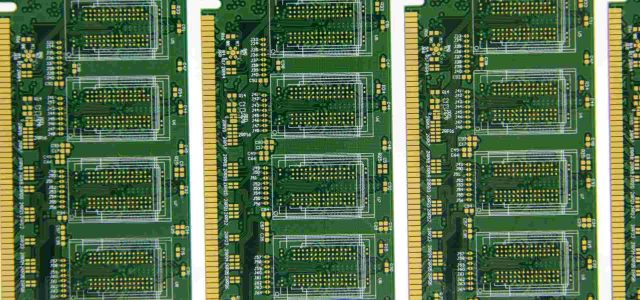

Small Batch PCB manufacturing refers to producing printed circuit boards in low to medium quantities, typically ranging from tens to several thousand pieces. Small batch PCB production is commonly used between the prototype stage and full-scale mass production.

Small Batch PCB services allow companies to validate product performance, conduct pilot testing, and support early product market entry while maintaining cost efficiency.

Why Choose Small Batch PCB Production?

Small Batch PCB manufacturing offers several important benefits for electronics development and production:

Flexible Production Volume

Small batch PCB production supports varying quantity requirements, making it ideal for pilot production and market testing.

Faster Time to Market

Low-volume PCB manufacturing reduces production preparation time and enables quicker product launches.

Lower Inventory Risk

Companies can avoid overproduction and reduce storage costs by ordering small batch PCBs.

Design Verification and Improvement

Small Batch PCB runs allow engineers to identify potential improvements before full-scale production.

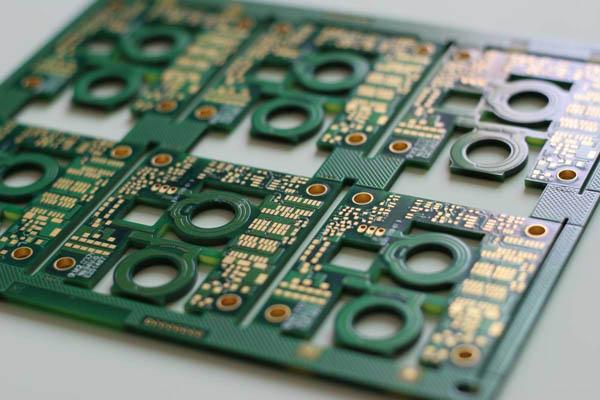

Small Batch PCB Manufacturing Capabilities

Professional Small Batch PCB suppliers typically support:

-

Single-layer to multilayer PCB manufacturing

-

HDI and high-density PCB structures

-

Controlled impedance PCB production

-

RF and high-frequency PCB manufacturing

-

Rigid, flex, and rigid-flex PCB fabrication

-

Special material and hybrid stack-up production

These capabilities allow small batch PCBs to meet diverse technical requirements.

Small Batch PCB Production Process

Small Batch PCB manufacturing follows a standardized production workflow:

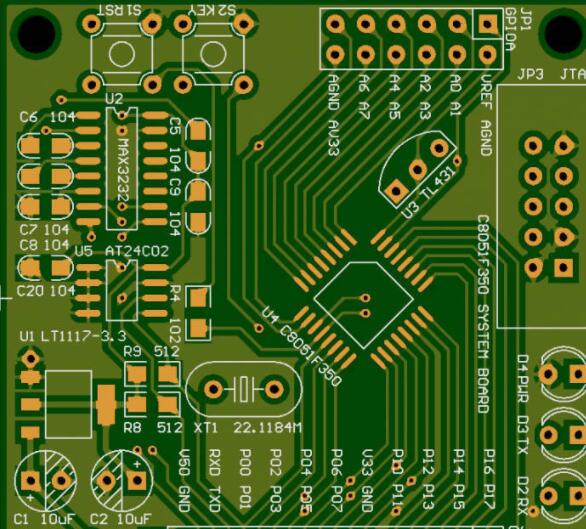

Engineering Review

Design files undergo DFM analysis to ensure manufacturability and production reliability.

PCB Fabrication

Boards are fabricated using advanced manufacturing processes and strict quality control.

Assembly and Testing (Optional)

Small batch PCB services can include SMT assembly, through-hole soldering, and functional testing.

Quality Inspection

AOI, electrical testing, and reliability testing ensure product quality.

Packaging and Delivery

Finished small batch PCBs are packaged according to customer requirements.

Applications of Small Batch PCB

Small Batch PCB manufacturing is widely used in:

-

Product development and R&D testing

-

Pilot production and engineering validation

-

IoT device manufacturing

-

Automotive electronics testing

-

Medical device product launch

-

Industrial automation equipment

-

Consumer electronics startup production

-

Semiconductor evaluation and testing systems

Small batch PCB services help bridge the gap between prototype and large-scale manufacturing.

Small Batch PCB vs Mass Production

Compared with large-scale PCB production, Small Batch PCB manufacturing provides:

-

Greater flexibility

-

Lower initial investment

-

Faster design iteration

-

Reduced supply chain risk

-

Easier product testing and validation

Small batch production is often the most efficient approach during early product commercialization stages.

How to Choose a Small Batch PCB Supplier

When selecting a Small Batch PCB manufacturer, companies should evaluate:

-

Engineering support and DFM capability

-

Production flexibility and lead time options

-

Material availability and technology capability

-

Quality control and testing standards

-

Supply chain reliability

-

Experience supporting prototype-to-production transition

A reliable supplier ensures stable quality and smooth production scaling.

Conclusion

Small Batch PCB manufacturing provides a flexible and cost-effective solution for pilot production, product validation, and early market launch. By supporting rapid production, design verification, and low-volume supply, small batch PCBs help companies accelerate product development while minimizing risk.

Working with an experienced Small Batch PCB manufacturer ensures consistent quality, reliable delivery, and scalable production solutions.