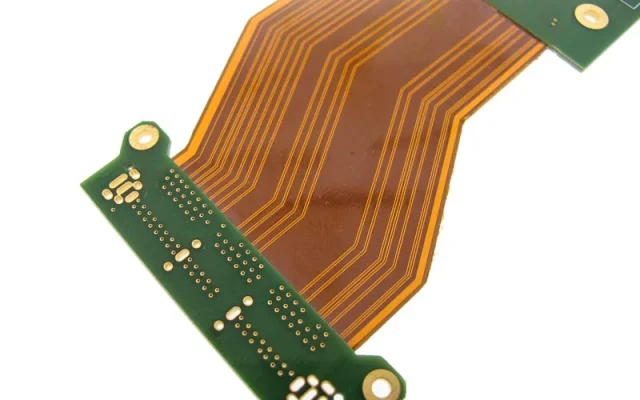

What Is a Rigid-Flex PCB?

A Rigid-Flex PCB is a hybrid printed circuit board that integrates both rigid PCB sections and flexible circuit layers into a single structure. Rigid-flex PCBs allow circuits to bend or fold while maintaining the structural strength and component mounting capability of rigid boards.

Rigid-Flex PCB technology reduces connector usage, improves signal reliability, and supports compact electronic product designs.

Structure of Rigid-Flex PCB

A typical Rigid-Flex PCB consists of:

-

Rigid FR-4 or high-performance rigid layers

-

Flexible polyimide-based circuit layers

-

Adhesive or adhesiveless bonding layers

-

Copper signal layers and ground planes

-

Protective coverlay for flexible areas

Rigid and flexible sections are laminated together to form a unified circuit structure.

Key Advantages of Rigid-Flex PCB

Rigid-Flex PCB technology offers multiple design and performance benefits:

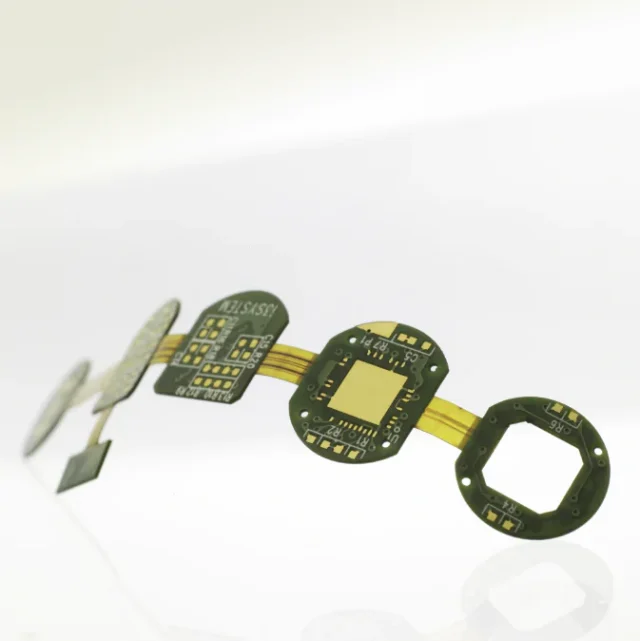

Space Saving and Miniaturization

Rigid-Flex PCBs eliminate connectors and cables, allowing compact product design.

High Reliability

Reduced interconnection points improve mechanical durability and electrical stability.

Improved Signal Integrity

Integrated circuit structure minimizes signal loss and electromagnetic interference.

Weight Reduction

Flexible circuit materials reduce overall product weight.

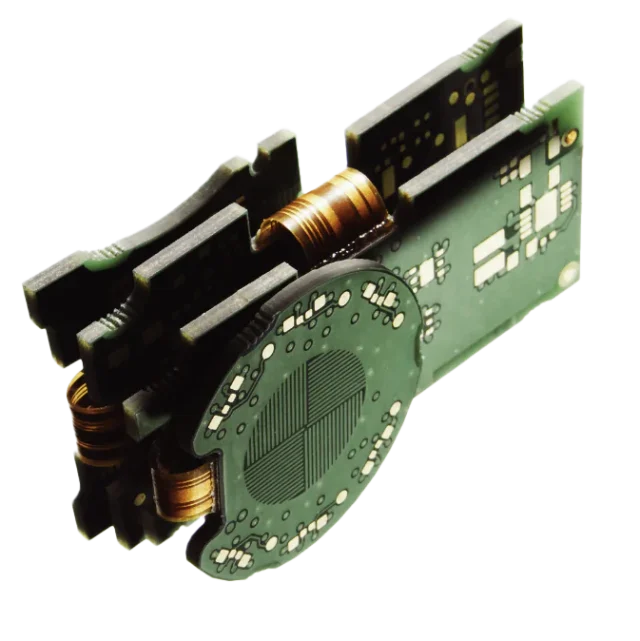

Enhanced Mechanical Performance

Rigid-Flex PCBs can withstand vibration, shock, and repeated bending conditions.

Design Considerations for Rigid-Flex PCB

Successful Rigid-Flex PCB design requires careful engineering planning:

Bend Radius Control

Proper bend radius ensures long-term mechanical durability.

Layer Stack-Up Optimization

Balanced stack-up structure improves reliability and prevents delamination.

Transition Zone Reinforcement

The interface between rigid and flexible areas must be carefully designed.

Material Selection

Common flexible materials include polyimide films with high thermal stability and flexibility.

Controlled Impedance

Rigid-Flex PCBs often require precise impedance control for high-speed signal applications.

Manufacturing Process of Rigid-Flex PCB

Rigid-Flex PCB fabrication involves advanced processes such as:

-

Multi-layer lamination combining rigid and flexible cores

-

Precision drilling and via plating

-

Laser drilling for microvias

-

Coverlay and solder mask application

-

Controlled impedance testing

-

Reliability and bending endurance testing

Strict process control ensures structural stability and electrical performance.

Applications of Rigid-Flex PCB

Rigid-Flex PCBs are widely used in industries requiring high reliability and compact design:

-

Aerospace and defense electronics

-

Medical devices and wearable electronics

-

Industrial automation and robotics

-

Consumer electronics and smart devices

-

Automotive ADAS and camera modules

-

UAV and drone control systems

-

Military communication equipment

-

Semiconductor and test equipment

Rigid-Flex PCB vs Traditional PCB Assembly

Compared with traditional rigid PCB assemblies connected by cables or connectors, Rigid-Flex PCBs provide:

-

Fewer assembly steps

-

Higher reliability

-

Better signal performance

-

Lower maintenance cost

-

Improved product durability

Conclusion

A Rigid-Flex PCB is an advanced circuit solution that combines mechanical flexibility with rigid board stability. By integrating multiple PCB technologies into one structure, Rigid-Flex PCBs enable compact, lightweight, and highly reliable electronic systems.

Choosing an experienced Rigid-Flex PCB manufacturer ensures accurate fabrication, stable material performance, and consistent product quality for complex electronic applications.