What Is OEM PCB?

OEM PCB (Original Equipment Manufacturer PCB) refers to printed circuit boards manufactured strictly according to customer-provided design files, specifications, and quality standards. In OEM PCB manufacturing, the supplier focuses on fabrication and assembly, while the customer retains full ownership of design and intellectual property.

OEM PCB services are widely adopted by electronics brands and system integrators that require stable quality, scalable production, and cost-efficient manufacturing without investing in in-house PCB facilities.

OEM PCB Manufacturing Capabilities

A professional OEM PCB manufacturer typically offers comprehensive capabilities, including:

-

Custom PCB fabrication

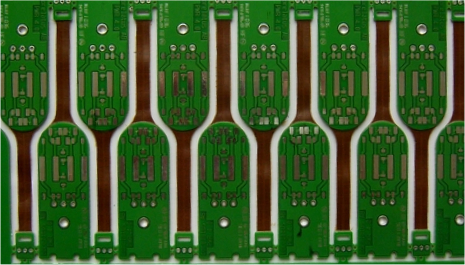

Single-layer, double-layer, multilayer, HDI, rigid-flex, and high-frequency OEM PCBs. -

Wide material selection

FR-4, high-Tg laminates, Rogers, Taconic, PTFE, metal-core, ceramic, and hybrid PCB materials. -

Precision process control

Tight tolerance control for trace width, spacing, thickness, and impedance. -

Surface finish options

ENIG, ENEPIG, OSP, immersion silver, HASL, hard gold. -

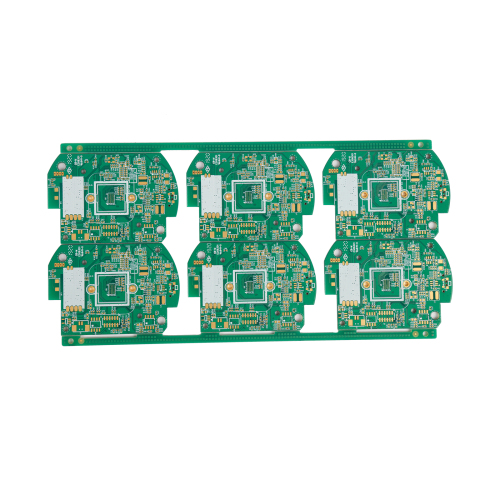

OEM PCB assembly (PCBA)

SMT, THT, mixed assembly, and functional testing.

These capabilities enable OEM PCB suppliers to support both prototype and mass production.

OEM PCB Manufacturing Process

A standard OEM PCB manufacturing process includes:

-

Engineering review and DFM analysis

Ensures manufacturability and reduces production risk. -

PCB fabrication

Imaging, etching, drilling, lamination, and surface finishing. -

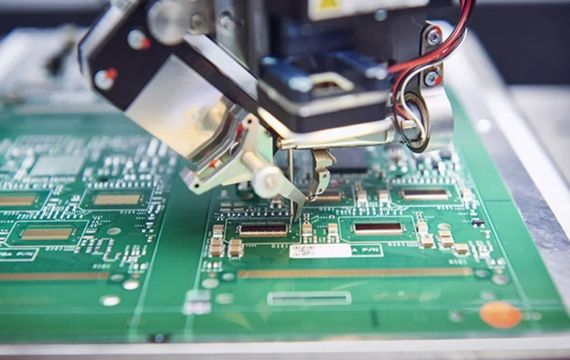

OEM PCB assembly (optional)

Component sourcing, SMT/THT assembly, and soldering. -

Inspection and quality control

AOI, X-ray inspection, impedance testing, and electrical testing. -

Packaging and delivery

Professional packaging to protect OEM PCB quality during shipment.

Strict process management ensures consistent quality and repeatability in OEM PCB manufacturing.

Advantages of OEM PCB Services

Choosing an experienced OEM PCB supplier provides key advantages:

-

Lower manufacturing and operational costs

-

Consistent and scalable production quality

-

Flexible order quantities from prototype to volume

-

Shorter product development cycles

-

Focus on core R&D and product innovation

OEM PCB manufacturing allows companies to bring products to market faster and more efficiently.

Applications of OEM PCB

OEM PCBs are widely used across various industries:

-

Consumer electronics

-

Industrial control systems

-

Automotive electronics

-

Medical devices

-

Telecommunications and networking

-

IoT and smart electronics

-

Test and measurement equipment

The flexibility of OEM PCB services supports both standard and highly customized electronic products.

How to Choose the Right OEM PCB Manufacturer

When selecting an OEM PCB manufacturing partner, consider:

-

Technical capability and production capacity

-

Quality management systems and certifications

-

Experience with similar applications

-

Engineering support and DFM expertise

-

Supply chain stability and lead-time reliability

A reliable OEM PCB supplier is not just a vendor, but a long-term manufacturing partner.

Conclusion

OEM PCB manufacturing is an efficient and reliable solution for producing high-quality printed circuit boards based on customer designs. With advanced manufacturing capability, strict quality control, and flexible service options, OEM PCB suppliers play a vital role in modern electronics production.

Choosing the right OEM PCB partner ensures stable quality, competitive cost, and long-term success for your electronic products.